Pipe vgp: technical characteristics, division into classes

Water and gas metal pipes are manufactured according to the existing GOST and are used for the construction of gas, water, heating systems and other more complex structures. Such products are characterized by certain parameters, which should be familiarized before using.

This is what we will do in this article.

Features of water and gas pipes

The considered products can have different variations according to some parameters:

| Parameter | Possible options |

| Zinc layer |

|

| The presence of a threaded connection |

|

| Manufacturing accuracy |

|

| Wall width |

|

| Manufacturing method |

|

Tip: if you plan to use such pipes in a system in contact with water, it is recommended to choose galvanized models. Their price, though higher, but they will last due to resistance to corrosive processes for much longer.

Technical details

Let's study the technical characteristics of the VGP pipe according to GOST 3262 75:

- Production material - steel in accordance with GOST 1050.

- The dimensions of the pipe VGP according to GOST 3262 75 in length usually range from 4 to 12 meters.

They can also be:

- measured length;

- multiple measured length;

- unmeasured length.

- Inner diameter may vary by? up to 6 inches.

- The outer diameter is from 10.2 to 165 millimeters.

- Weight per meter depends on the cross section and, accordingly, can take values from 0.4 to 17.81 kilograms. According to GOST 10706 due to the strengthening of the weld, an increase in mass of 1% is allowed.

- Conditional pass, which is indicated in the marking of two letters DU - from 6 to 150 millimeters.

To find out the exact weight of an AIV pipe or another important parameter before purchasing it, take a look at the special table, which must be in each specialty store:

Groups

Water and gas pipes have the following division into groups:

| Group | Product Features |

| BUT | They are made from ordinary steel, for them only mechanical qualities are standardized. |

| B | Production is possible, both from ordinary and lightly alloyed steel, for them only the chemical structure is normalized. |

| AT | It is possible to produce both ordinary and lightly alloyed steel, for which mechanical qualities and chemical structure are standardized. |

| D | Possible hydraulic loads are normalized. |

Classes

The instruction also assumes the presence of several classes:

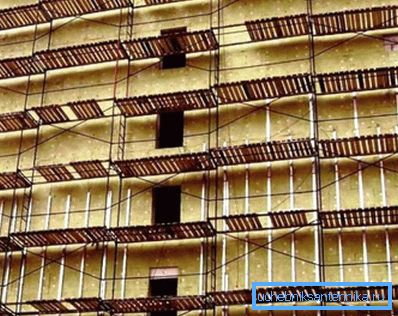

- The first. Metal pipes, simple in their structure, without any special requirements. They are used in the construction of scaffolding, all kinds of supports, fences, laying of wires, installation of gas and water supply pipelines. This is the most common class for household use.

- Second. Excellent withstand low and high pressure in the water mains, gas pipelines and oil pipelines.

Tip: if there is a significant pressure in the pipeline, it is not recommended to use products below the second class, as they may not withstand this level of operation.

- Third. Suitable for use in the food and chemical industries, furnaces, boilers and even in nuclear equipment due to the ability to withstand pressure at high temperatures.

- Fourth. With their help, oil fields are being developed for the subsequent implementation of its production.

- Fifth. Structural products that form the framework of transport equipment, bridge cranes, tower masts and others that require increased reliability of objects.

- Sixth. Components such as bearings, shafts, pistons experience extraordinary loads during their operation, so when they are created, sixth grade GVP pipes are used, which are manufactured using a special technology.

Conclusion

The products under consideration are very widespread in various industrial and domestic industries. Compliance with strict standards allows high-class models to be used not only as highways for transporting liquids and gases, but also to act as structural components of engine cranes, oil rigs and other sophisticated equipment (see also the article Steel water pipes: options, pros and cons standards).

The above specifications will help you navigate in their diversity. The video in this article will provide your attention to additional consideration of materials of direct relevance to the topic outlined.