Pipeline fittings - types and their features

The pipeline system in addition to flat sections of pipes usually has all kinds of twists, branches, transitions from one diameter to another and other elements. For their installation using special fittings, which, in fact, this article is devoted.

General information

Pipeline connecting elements or, as they are also called, fittings perform several functions. Besides the fact that they allow to form the necessary element of the pipeline, for example, branching or transition, the fittings ensure the tightness of the joints and, at the same time, are responsible for the reliability of the system.

Accordingly, the durability of the entire pipeline depends on them. Therefore, the choice of fittings must be approached no less responsibly than the choice of the pipes themselves. And for this you need to familiarize yourself with all their existing species, which we will do further.

Types of compounds

First of all it should be said that the connection of pipelines is of two types:

- Detachable - these include compounds obtained by soldering, welding, pressing, concreting or gluing.

- All-in-one - threaded, flanged, bell-shaped and so on.

Types of pipeline connections depend on the material from which the parts are made, as well as on the following factors:

- Physico-chemical properties of the transported product, such as toxicity, aggressiveness, ability to precipitate, etc.

- Operating conditions - the need for frequent disassembly, system pressure, explosion safety, etc.

Depending on the type of connection of the elements of the pipeline, fittings are also selected. But, besides the type of connection, the fittings differ in purpose.

Most often in the pipelines are the following details:

- Elbows;

- Tees;

- Transitions;

- Couplings

Now take a closer look at their types and purpose.

Taps

The main function of the taps is to change the trajectory of the pipe and the direction of the workflow. This type of fitting is one of the most common pipelines. Visually, this detail can be represented as a pipe section bent at a certain angle.

Of course, in pipelines of small diameter, you can make a turn by bending the pipe with your own hands, but if the diameter is large, then you will not be able to bend the pipes.

Therefore, the taps are used in various types of systems:

- In chemical pipelines;

- Water pipes;

- Heating mains;

- Gas pipelines, etc.

According to the method of manufacture, the connecting pipe bends are distinguished by:

| Bent | These products are characterized by angles of 3–90 ° with a gradation of one degree. They are made, as it is not difficult to guess from the name, by bending in a cold way or under the influence of high temperature. |

| Stamped | Made by stamping blanks and their subsequent welding. |

| Made by pulling (seamless bent) | These products are performed by pulling over the horn-shaped core. A feature of seamless bent bends is the slight radius of curvature. |

| Welded sectional | Performed by welding pipe scraps. |

The most common are stamped bends and made by pulling.

With regard to structural features, the most popular are the curved products, i.e. having a small radius and characterized by the following angles of rotation:

- 45 degrees;

- 60 degrees;

- 90 degrees;

- 180 degrees.

Recently, stainless steel bends, which are made of steel containing chromium, are very popular when installing various types of pipelines. Their advantage is resistance to corrosion and various aggressive media.

Note! A variety of corner angles allows for the best system throughput. After all, the rotation of the pipeline at an angle of 90 degrees is the most common source of turbulence, as well as a catalyst for the clay sediments in the system.

The classification of swivel joints can also be performed according to two criteria:

- Construction material;

- According to the technology of installation of this element in the pipeline.

For the installation of steel systems, the corner bend is a threaded sleeve, the body of which is bent at a certain angle. However, there are similar fittings for a welded joint, in this case their inner and outer diameter equals the inner and outer diameter of the pipeline.

In plastic pipelines, depending on their type, the connection is welded and socket-shaped.

Tees

This type of fitting is installed in places where it is necessary to branch the pipeline.

Depending on the ratio of the neck of the tee to the body of the tee, they are distinguished by:

- Transitional - have a different diameter of the neck and the passage openings of the body. They are used in areas where the branch pipeline is different in diameter from the central one.

- Equal tees - have the same diameter of the neck and the through holes of the housing.

It should be noted that the tees are related to those parts of the pipeline that are subjected to high dynamic loads and pressure. Therefore, they are subject to high demands regarding reliability and durability.

By scope, tees are divided into:

- Products for work in medium aggressive and low aggressive media are made of carbon steel grades - 10, 20, StZ.

- Products for work in highly aggressive environments are made from alloyed and high-alloyed steels of grades 5X5M, 15XM1, 12X18H10T, etc. Of course, the price of such parts is higher.

Manufacturers use different methods for manufacturing tees:

- Mold casting method;

- By cutting gas parts and their subsequent welding;

- By stamping one-piece forging and then drilling holes;

- By stamping steel sheet and subsequent welding.

Transitions

Transitions are called parts that allow you to smoothly change the diameter of the pipeline.

To date, there are many different options for adapters, which are divided primarily into:

- Stamped;

- Welded.

The main characteristic of adapters is the input and output diameter, as well as the transition length. In addition, products may differ in the material from which they are made.

Perhaps the most widely used transitions from stainless steel, which are used in the following areas:

- Chemical - due to resistance to aggressive environment;

- Food - due to environmental friendliness;

- Energy - as a result of strength and durability.

The need for a transition can be caused by a variety of reasons. For example, reducing the diameter will increase the pressure in the pipes and, consequently, increase the pressure. Expansion allows to achieve the opposite effect.

Thus, the transitions are the most valuable part for the distribution of pressure and planning loads on the system. As with tees, transitions are subject to increased requirements with respect to reliability and durability.

Currently, there are several ways to manufacture these parts:

- Forging ring-shaped or stamping of conic forgings with their further mechanical processing;

- Rolling from sheet blanks and subsequent welding;

- Stamping from sheet blanks and subsequent welding;

- Stamping from tubular blanks by crimping or dispensing.

By way of installation, the transitions can be both collapsible and welded.

Note! Welded pipe joints according to GOST 16037-80 are allowed only if the fittings are made of the same steel grade as the pipes.

Flanges

Flanges are parts in the form of a disk (sometimes in the form of a square frame), designed to connect pipes of the same diameter with bolts. This connection is used primarily at the points of connection of pipelines to equipment that has counter flanges, as well as at sections of pipelines that require periodic replacement and disassembly during operation.

These parts differ in the way they are connected to the pipes.

They are:

- Welded;

- Threaded.

Flanged welded connections according to GOST 12815-80 are divided into:

- Flat welded (welded in two seams);

- Loose on the weld ring;

- Welded butt.

For connecting pipes made of alloyed steel, use free flanges that rest on the flanged end of the pipe. The connection on the thread, as a rule, is used for high pressure pipelines.

The dimensions of the flanges are standardized, which ensures their interchangeability in pipelines.

This applies to:

- Outer diameter of the part;

- The diameter of the bolted circle;

- The diameter and number of bolt holes.

For tightness of flange connections, a special gasket is used between them, the shape of which depends on the properties of the transported liquid or gas and the pressure in the system.

According to GOST 12815-80, there are eight types of sealing planes flanges:

- With a ledge;

- With connecting tab;

- With a hollow;

- With groove;

- With thorn

- Under the oval gasket;

- A groove for fluoroplastic gaskets;

- Under the lens gasket.

It should be noted that the tightness of the connection depends largely on the quality of gaskets.

Therefore, they are subject to the following requirements:

- Elasticity;

- Strength;

- Strength;

- Thermal resistance;

- Chemical resistance

Note! The instructions for use of threaded and flange connections do not allow their use for pipelines laid in places difficult to access for inspection.

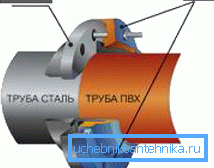

Couplings

The coupling is a part whose inner diameter is equal to the outer diameter of the pipes being joined. These connections can be used for the installation of collapsible and monolithic pipelines. In the first case, use threaded couplings, and in the second - glue or under the welded connection.

I must say that in any case, the coupling provides a tight connection. The pipeline material can be any, the most important thing is that it coincides with the material of the coupling.

In fact, the coupling is an alternative to the flange connection. For example, in steel pipelines, it, like flanges, allows for the dismantling and replacement of individual sections of the system. Since metal pipelines are not too durable, this possibility is very popular.

It should be noted that there is another type of couplings - bell-shaped, which are used in non-pressure pipelines, for example, in sewer systems. The connection is then made using rubber seals.

Conclusion

As we found out, even the same fittings for pipelines are of several types. Therefore, their choice should be approached very carefully. High-quality and properly selected parts will increase the life of the pipeline.

From the video in this article, you can get more information on this topic.