Pipeline laying: methods and materials for highways and

What methods are laid pipes for water supply? How is the polypropylene pipe laid at the hot water supply to the cottage? How are the main water pipelines under busy motorways and building foundations? In the article we will try to acquaint the reader with some aspects of the performance of these works.

A private house

Let's start with information that has practical value for owners of cottages. What is the water supply input made from and how does it fit into the ground?

Material

Typically, only cold water is put in the cottage. Hot water and heating is organized on its own; gas, electricity, firewood, coal, pellets (pressed pellets from sawdust), etc. can be used as heat sources.

In this case, the most efficient use of polyethylene pipes.

Why?

- Polyethylene is extremely durable. The service life of the pipe is estimated at least 50 years.

- It is resistant to corrosion (as, indeed, all other polymers).

In addition: polyethylene is extremely resistant to aggressive media. It is from this plastic, along with the glass, that dishes are produced, in which concentrated acids and alkalis are supplied.

- Polyethylene - dielectric. If so, you can not be afraid of stray currents and the occurrence of electrochemical processes that destroy the valves.

- Its surface is not overgrown with lime deposits., which distinguishes the material from any steel pipes.

- In favor of polyethylene pipes says their price.: at the same throughput it is 1.5-2 times lower than that of non-galvanized steel.

- Finally, polyethylene retains its elasticity at low temperatures.. In practical terms, this means that even when the water freezes, the pipe will not be broken by the pressure of ice: the shell will only stretch a little, and when defrosting it will return to its original dimensions.

The input from the water meter assembly in the well is laid with a one-piece pipe: with a diameter of up to 180 mm it is supplied in coils and coils. Wiring in the house can be done, of course, with other materials; as an adapter mounted compression fitting.

And what better to use in the case when hot water supply and heating are provided by connecting to the heating main?

- When overhead laying input traditionally used steel pipe. Connections are mounted by welding or on threads; thermal insulation is made of glass wool with fiberglass or galvanized iron sheath.

- When underground installation is preferable to use reinforced polypropylene pipes.. It is reinforced - because they have greater tensile strength and have a lower elongation when heated. To connect straight lengths, low-temperature socket welding is used; Aluminum reinforcement requires pre-stripping in the field of welding.

Nuance: if the polyethylene pipe when laying can be bent with a radius of at least five of its diameters, then the turns of polypropylene bushings are carried out only by fittings.

Laying in the ground

At what depth do they lay water pipes when laying the entry into the ground?

To answer this question, we turn to the regulatory documents.

- According to SNiP 2.04.02-84, the depth of laying of water pipes, counting to their lower surface, should be at least half a meter more than the maximum depth of penetration into the soil of zero temperature (freezing depth).

- The code of the rules of joint venture 40-102-2000 makes an addition: this depth can be reduced by using non-hygroscopic thermal insulation.

For the convenience of the reader, we present the values of the depth of freezing for some regions of the post-Soviet space.

| Cities | The depth of freezing, m |

| Kaliningrad, Simferopol | 0.7 |

| Frunze, Dnepropetrovsk | 0.8 |

| Rostov-on-Don, Kiev, Minsk, Riga | 0.9 |

| Tallinn, Kharkov, Astrakhan | 1.0 |

| Pskov, Kursk, Smolensk | 1.1 |

| Voronezh, Volgograd, St. Petersburg | 1.2 |

| Tver, Moscow | 1.4 |

| Vologda, Saratov, Penza, Kostroma | 1.5 |

| Uralsk, Samara | 1.6 |

| Kazan, Izhevsk, Ulyanovsk | 1.7 |

| Orenburg, Ufa | 1.8 |

| Chelyabinsk, Perm, Sverdlovsk | 1.9 |

| Kurgan, Kostanay | 2.0 |

| Tobolsk, Petropavlovsk - Kamchatsky | 2.1 |

| Omsk, Novosibirsk | 2.2 |

Why are water pipes laid at great depths? Everything is obvious: in the absence of water pumping at ambient temperatures below zero, they will simply freeze. At the same time, deep laying solves the problem of pipe deformation when moving along the surface of a motor vehicle.

Note: insulation of water supply does not guarantee its protection against freezing. It only makes freezing slower. Radically the problem of defrosting when laying pipes at a shallow depth is solved only by a heating cable laid in a common insulating jacket with them.

Highways

How are the water mains laid?

Materials

Until recently, when laying intracity water supply systems massively used:

- Cast iron pipes with a flared seal with a cabol (impregnated with bitumen organic fiber) and molten lead. Cast iron corrosion resistance allows many laid age and more back lines to remain in service today. The main problem of the material is its fragility: ground movement leads to accidents.

- Black steel Its use is one of the insanities associated with attempts to save money; the service life of the steel water supply system before the first accident, generated by its corrosion, was no more than 10-15 years.

In addition: due to rust and lime deposits, the lumen of the pipe during this time was reduced to 25-40 percent of the original. Guess how it affected the pressure of the water?

Fortunately, progress does not stand still, and now more curious solutions have spread.

- Pipes from VChSHG (nodular cast iron with nodular graphite) possess the corrosion resistance of cast iron and the ductility of low carbon steel. The tightness of the socket connections is ensured by rubber o-rings.

- Polyvinyl chloride pressure pipes are connected by sockets and pipe couplings using the same rubber O-rings or adhesive joints.

- Finally, polyethylene main pipes are joined by low-temperature butt welding: the ends of adjacent pipes are melted with an electric heater and pressed against each other. Alignment and clamping with a large trunk diameter are performed using mechanical or (with a cross-section of more than 250 mm) hydraulic devices.

Laying in the ground

If oil and gas pipelines and heating lines can be laid above the ground level and directly on its surface, then the main water supply systems, as described above, are buried in the ground.

The traditional styling scheme is clear and familiar:

- A trench is digging along the future highway;

- The pipeline whip welded or connected in other ways is laid in a trench on a sand pillow and covered with soil.

Under roads with heavy traffic, pipes are often placed in a reinforced concrete chute, which does not allow them to be damaged when the surface is under considerable stress.

It is clear that this is not the most practical way: a huge amount of earthworks and the need to restrict traffic will hardly please the workman and the citizens.

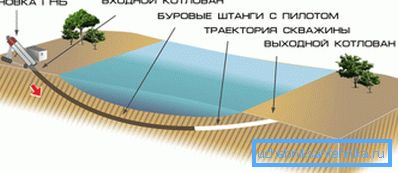

In 1971, a new era began in the construction of urban underground pipelines: Martin Cherrington (USA) was the first to test the laying of pipelines using the HDD method (horizontal directional drilling). The essence of the method is clear from its name: the pipe does not fit into the trench, but is passed under the surface without disturbing the upper layers of the soil.

Currently, trenchless pipe laying is practiced in several ways:

| Method name | Short description |

| Horizontal directional drilling | Moving articulated drill rods with a pilot (direction correction system) run through a horizontal section along a gentle arc. If necessary, the channel can be expanded by multi-stage re-penetration. Then the finished pipe whip is pulled into the well; in parallel with it, a bentonite solution is supplied, which serves as a lubricant and cementing the walls. |

| Horizontal puncture | It is applied when laying the pipeline under highways or the bases. A steel pipe is placed in an open well, later used as a casing for the pipeline; its front edge is provided with a cone. The pipe is pressed through the soil with jacks with an effort of hundreds of tons; the soil is not removed, but compacted around the casing. To speed up the puncture vibro-impact and pneumatic impact machines can be used. |

| Pipe clogging | The pipe of large diameter with sharpened edge is pressed by jacks. The soil trapped in its cavity is removed from there mechanically or manually. |

| Pipeline rehabilitation | The shock head moves along the old pipeline, destroying it and pressing the pipe remains into the ground around it. Behind it stretches the whip of the new pipeline. |

SNiP 3.05.04-85

How to be guided when building a water supply system with your own hands? Basic instructions for the design and piping are contained in SNiP 3.05.04-85 External networks and water supply and sewage facilities. We give some requirements of this document.

So, how should the pipeline be laid according to the SNiP?

- For socket joints with rubber seals, the angle of rotation at each joint should not exceed 2 degrees for diameters up to 600 mm and 1 degree for diameters from 600 mm.

- Deviations from the design axis of the pipeline should not exceed 100 mm.

- Rubber seals on socket connections cannot be used primorozhennymi.

- Steel and reinforced concrete pipelines are protected from corrosion.

- Welding between each other polymer pipes (in particular, HDPE and LDPE) is not allowed.

- Welding of steel pipes can be carried out at a temperature not lower than -50 degrees, polyethylene - not lower than -10 degrees.

Conclusion

We hope that we were able to satisfy the reader’s curiosity in the field of methods of laying water pipelines and the materials used for this purpose. As usual, additional information can be found in the video in this article. Successes!