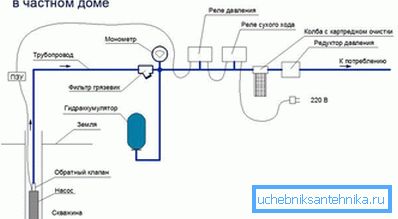

Pipeline water pressure

The most probable causes of disturbances in the operation of the water supply system in a private house are, as you know, corrosion of the pipe walls, the deposition of salts on them, and the high pressure of water in the pipeline. Taking into account the fact that in recent years their plastic counterparts are replacing metal pipes more and more often, only the last two reasons listed above represent a real threat to your water supply system. The issue of combating salt deposits does not fall under the theme of our article (although they affect partly the pressure indicators in pipes), in connection with which we will consider only the last factor.

To prevent possible problems, you should familiarize yourself with the passport attached to them and make sure that they are able to withstand the pressures provided for in your water supply system before purchasing pipe products.

Tip! Increased pressure in the system entails an increase in water consumption.

This leads to additional energy consumption consumed by pumping equipment, which ensures the continuous circulation of water in the system.

Pressure value

It is well known that maintaining the normal level of water pressure in pipes is the most important condition for the operation of the water supply network, as well as its long-term and trouble-free operation. In this case, the pressure in the pipeline may differ significantly from the fixed average, normalized for household plumbing systems.

So, for example, for normal operation of a kitchen valve, the pressure of the carrier in the water supply system should not be less than 0.5 bar.

But in real terms, the value of this indicator, as a rule, is somewhat different from the specified value. That is why when accepting the water supply system (after its repair, in particular), it is desirable to check the working pressure for compliance with the established standards.

Well, in the case of self-laying of pipelines before starting work, one should carefully read the basic requirements for household plumbing systems, as well as the generally accepted order of their arrangement.

Pressure balancers

Consider some devices that will help equalize the pressure.

Expansion tank

To equalize the water pressure in domestic pipelines, special tools can be used to remove excess media. Moreover, the excess pressure in the system can be compensated very simply - for this, a so-called expansion tank is installed in it, which takes over all the excess media.

In accordance with its design, all known samples of expansion (compensation) tanks are divided into devices of open and closed type. They are very often used in the hot water supply systems, as in this case the probability of the formation of pressure drops in the system is very high. This is due to the fact that the coolant in the process of its circulation through the network (from the "return" - to the heating boiler, and then back into the system) slightly increases its volume.

Tip! When the water temperature changes by 10 ° С, for example, the rate of expansion of the coolant in the system reaches 0.3% of the total volume of liquid in it.

The disadvantage of open-type expansion devices is that their installation puts the system into a mode that is characterized by low coolant pressure and, as a result, poor handling. In addition, in an open system, there is a gradual evaporation of the carrier. You will need additional efforts for its continuous recovery.

To all of the above, you can add the fact that due to the openness of the tank, fresh portions of air constantly flow into it, which causes an acceleration of the corrosion processes in the system.

Tip! Since open-type expansion tanks should be placed in the uppermost part of the building, they require compulsory insulation. It is clear that the cost of the entire water supply system as a whole in this case increases markedly.

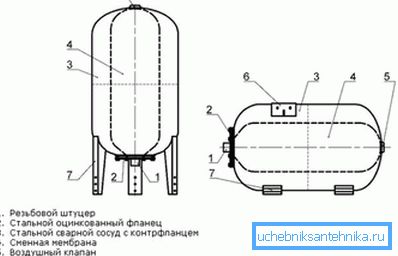

It is possible to avoid all the above troubles due to the use of a tank of a closed type as a compensation device, the installation site of which, as a rule, is not standardized. These tanks are equipped with a built-in membrane mechanism that allows you to adjust the pressure of the carrier in the closed mode.

Accumulator

In addition to the compensation tanks in the water supply systems, so-called accumulators can be installed, used to protect the pipeline from such a dangerous phenomenon as a water hammer.

The phenomenon of water hammer is usually manifested when an emergency shutdown of pumping equipment from the network or when there is a sharp closing (opening) of the water intake valve. The resulting dynamic loads can significantly exceed the permissible values for a particular pipeline. Note that such devices are usually operated in pipelines with drinking water and allow you to create a small supply of media that can be automatically redirected back to the system (in the event of a decrease in pressure in it). Like in the compensation devices considered earlier, accumulators can be operated in a closed or open form and have all the above disadvantages.

Tip! At the same time with hydraulic accumulators, it is recommended to place expansion tanks of small capacity (about 0.2 liters) in water extraction points.

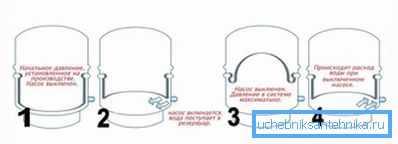

The principle of operation of the hydraulic accumulator

When studying the design of the simplest closed-type hydraulic accumulator, we find that its action is based on the same membrane mechanism (similar to the expansion tank). In a closed volume, the membrane is in a steady state, balanced by approximately equal pressures of the coolant and the air bubble located on opposite sides of the partition. . This change is automatically transmitted to the sensitive element of the built-in relay, which shuts off the pump when this parameter reaches a certain value.

In the process of water consumption in the system, its pressure decreases markedly, which again leads to the relay triggering, but now for switching on. Hydraulic indicators

The calculation of carrier pressure sufficient for the normal functioning of your water line will allow you to accurately determine the samples of tubular products purchased before its installation. It should be remembered that the limit values of pressure in the network are usually associated with the following indicators:

- the upper and lower thresholds of fluid pressure, for which the compensatory devices of a closed type installed in the network (expansion tank and accumulator) are designed;

- pressure values that create conditions for the normal functioning of household appliances that are dependent on water supply (a washing machine, for example);

- limit values of pressures for which the pipes purchased by you and the accessories attached to them (valves, tees, mixers, etc.) are designed.

Tip! The unit for measuring the pressure of a carrier circulating in water mains is 1 bar (or 1 atmosphere). The value of this indicator for urban water mains (according to the requirements of the currently valid SNiP) should be about 4 atmospheres.

Also note that the valves installed in the heating pipeline, mixers, as well as the pipes themselves must withstand short-term pressure surges of up to 6 atmospheres. When buying basic samples of household equipment connected to your water supply network, you should choose models that have a small margin of safety in terms of the limiting factor. Such forethought will allow you to protect them from sudden pressure surges in the network caused by hydraulic shocks.

It is very important that the water pressure in the water supply system of a private house has a level that allows you to simultaneously include several consumption points at once, which can be achieved with a minimum of 1.5 bar.

For direct reading of pressure in the water supply network, standard measuring manometers are used with a standard linear scale, calibrated in appropriate units.

Service recommendations

According to the requirements of SNiP, the operability check of devices in the heating network, as well as the status of all auxiliary equipment should be carried out at least once a year.

During this test, first of all, the presence of leaks in the water supply system and the resulting pressure drop is established. After all the leaks are repaired, it will be necessary to check the pressure in the water supply system as indicated by the pressure gauge installed on the main hydraulic accumulator.

In the normal operation of the system, the reading of this device should be close to the minimum value (Pmin). With a noticeable difference from Pmin (more than 10%), you will need to try to increase the pressure to the desired rate by turning on the pumping equipment operating in your network. If the water pressure in the heating network increases (immediately after the pump stop relay triggers), it will be necessary to make pressure measurements again, but now in the shutdown mode. The specified parameter, by analogy with the previous case, should not differ from the Pmax value by more than 10%.