Pipes for heating: an overview of 3 options for arranging an

To build a water heating system, you need a powerful heating boiler and high-quality radiators. But no less important are the pipes for heating, which serve to transport the coolant and connect all the necessary elements into a single network.

Instructions for choosing the most suitable parts are presented to your attention below.

Requirements

Before answering the question of which pipes to use for heating, it is necessary to determine the most important technical characteristics of the parts to which attention should be paid when purchasing them.

So, pipelines and fittings used for water heating must meet the following requirements:

| Centralized coolant flow | Autonomous heating system |

| Temperature | |

| The heating pipe in city apartments, where hot water is heated in the boiler room and supplied through main canals, must be able to withstand temperatures up to 95 degrees Celsius. This is provided for by building codes. | Heating pipes connecting an autonomous gas or electric boiler with batteries must transport the coolant with a temperature not higher than 75 degrees Celsius. If masking of the heating pipe in a screed or installation of a heated floor is intended, then the water temperature will not exceed 35aboutWITH. |

| Pressure | |

| If the pipes for heating are laid in the apartment, you should choose such parts that can withstand a constant pressure of 5-6 atmospheres. However, abrupt hydro and pneumatic shocks are possible, therefore it is advisable to buy pipes that do not collapse even at 20 atmospheres of internal pressure. | Autonomous engineering networks operate at much lower loads. Thus, pipes for heating systems equipped with individual heaters must withstand a pressure of a maximum of 1-2 atmospheres. As for the water hammer, then with the correct operation of the equipment they are absolutely excluded. |

Note! The above are not all the criteria for the selection of pipes. In particular, do not forget to choose the size of the parts correctly (otherwise the battery and boiler nozzles simply do not dock with the pipelines). A significant impact on the purchase price and has a manufacturer.

For example, Czech products Ecoplast have excellent characteristics and quite affordable cost. Well and the last - simplicity of installation by the hands. Steel pipes, though durable, but flexible polymer parts are much easier to run through the rooms and dock with each other.

To make it easier for you to decide which pipes are needed for the heating system, we’ll consider some options in more detail.

Varieties of products

Option 1. Of steel

Pipes from ordinary carbon steel has been used for the manufacture of plumbing and heating systems for a very long time.

This is due to their two features:

- the highest strength - the parts withstand the internal pressure of water exceeding 20 atmospheres, and do not collapse from external and internal physical effects, including shock;

- excellent heat resistance - the pipes will retain their integrity even if water is poured over them with a temperature of more than 150 degrees Celsius.

Note! These figures are for guidance only. If you install steel pipes in the heating system, this does not mean that the engineering network will withstand such loads. The weak link may be nozzles, taps, pumps, filters, and so on.

On the other hand, the use of such parts is gradually abandoned, because, along with the advantages, steel has several rather significant drawbacks:

- Susceptibility to corrosion. Depending on the diameter and thickness of the walls, steel pipes in heating systems can last from 10 to 20 years, after which they will become unusable. And we are talking about the formation of rust both inside pipelines and outside.

Tip! To protect the external parts of the climate network from the negative impact of the environment will help banal primer and protective enamel. Covering pipes from time to time with paint, you will significantly extend their life.

- Reducing the internal cross-sectional area. Steel pipes are clogged with mineral deposits, rust particles and other elements during operation. Over time, their capacity drops, which negatively affects the functioning of the climate system.

- Installation difficulty. During installation, you must use special equipment for bending and joining parts, as well as to have certain skills and abilities to work with a gas burner.

Another point is the non-aesthetic appearance. Steel risers do not allow concealed laying in the walls and floor, so they will always be visible. To give them an aesthetic appearance, use a variety of screens and pads on the heating pipe.

The most popular and efficient way is to install highways in boxes made of drywall. This method will perfectly hide all non-aesthetic-looking elements even if the distance between the heating pipes is large enough.

Note! In addition to steel, there are also cast iron pipes for heating. However, they are more often used in steam rather than water heating systems, as well as in the design of heat exchangers in industrial plants.

Option 2. Stainless steel

The disadvantages of steel parts, which were mentioned in the previous section, lack a stainless pipe for heating. And we are talking not just about a different composition of the material, but about a completely different design.

Here are just some of the features of a modern stainless steel pipe used for mounting climate systems:

- with a wall thickness of 0.5 mm, they are perfectly bent by hand and retain the diameter of the inner cross section at the bend, avoiding creases;

- connected with fittings with high-strength silicone seals;

- maintain the internal pressure of the heat carrier exceeding 15 atmospheres at a temperature up to + 150 degrees Celsius.

These parts have only one, but a significant drawback - stainless pipes are quite expensive. Therefore, the most widespread installation of climate systems received plastic, with many advantages at very affordable prices.

Option 3. Of polymers

The market for plastic pipes that can be used for arranging heating networks is quite diverse.

The following varieties are popular:

- Metal plastic. These pipes were widely used in private construction at the end of the 20th century, but now their popularity has declined significantly. The fact is that although the pipes themselves, reinforced with foil, are strong enough, the tightness and service life of compression fittings used to connect parts with each other leave much to be desired.

Press-fittings help avoid problems, but special tools and skills are needed to work with them.

As for the technical characteristics of metal pipes, they are:

- maximum pressure - from 12 to 15 atmospheres;

- coolant temperature - up to 95 degrees Celsius.

- Polypropylene. Pipes from this type of plastic are used much more often. Differ in the increased durability, but do not love too high temperature of the heat carrier.

The same previously mentioned ecoplastic can transport liquid under pressure up to 20 atmospheres, however, if the water temperature rises to 95 degrees, this figure immediately drops to 6.

Polypropylene is great for installation in stand-alone systems with gas and electric boilers. However, installation in urban apartments with a centralized flow of coolant is better to refuse, because water hammer can easily destroy your climate network.

Tip! For heating it is better to use reinforced polypropylene. It is not only more durable, but also has a lower coefficient of thermal expansion. It is possible to install sufficiently long sections of pipes without the use of compensating loops or bends.

- Crosslinked polyethylene. The main quality of these pipes is flexibility. Maintain pressure to 10 atmospheres at a temperature of 80 degrees.

Ideal for standalone radial type wiring systems. Also widely used in the arrangement of floor heating systems.

Sold in the form of bays, so you can lay segments of any length. They can be bricked up in a screed, but it must be ensured that not a single fitting connection is poured with concrete, otherwise you will have to dismantle the screed in case of leakage.

Types of wiring

Whatever pipes for heating and water you choose, you should properly install them. The work should be done in such a way as to ensure uniform distribution of the coolant over all radiators and other elements of the system.

There are several common options:

- Heating in one pipe. This type of wiring was previously used in the construction of apartment buildings. Another name is Leningrad. It is a ring of pipes, laid along the perimeter of the house, to which radiators are docked in a parallel or sequential way.

This is the simplest scheme, requiring a minimum number of pipes and fittings.

The disadvantages of this solution are obvious:

- the inability to regulate the temperature in individual rooms with thermostats;

- if a radiator breaks down or leaks, you cannot replace or repair it without stopping the operation of the entire climate system and draining the coolant;

- Radiators that are closer to the boiler heat up more than the elements mounted in the far rooms, so it is necessary to correctly select the number of sections in the heating devices.

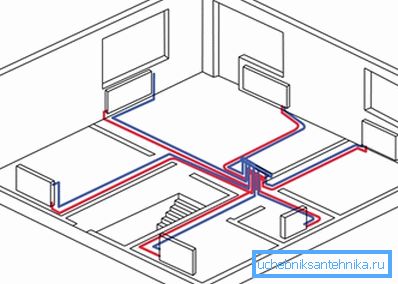

- Double pipe layout. In this case, one main pipeline supplies the coolant to the radiators, and the second - return flow - delivers the cooled liquid to the heating boiler.

Although the two-pipe installation method is more expensive, its advantages will not make you give up on your choice:

- all elements of the heating system are heated uniformly;

- With the help of automatic or manual regulating valves, you can increase or decrease the volume of fluid flowing into the battery, thereby changing the temperature in the premises;

- when leakage occurs, it is possible to cut off the damaged area with a crane, without overlapping the coolant current to other elements of the system.

Note! In addition to the above options, there is a three-pipe heating system, as well as four-pipe and radial. These are quite exotic options that are used in cases when it is necessary to organize several heating rings with different temperature of the heat carrier (for example, for radiators and floor heating systems).

Conclusion

Pipes for heating is undoubtedly an important element of the heating system, as the durability and efficiency of the climate network depend on their quality, tightness and strength. In order not to have problems for 10-15 years of operation, also buy high-quality fittings, valves and other parts required for installation.

For more information about the design of engineering systems of a private house, see the video in this material.