Pipes for ventilation: the choice between metal and plastic,

Ventilation system according to sanitary and hygienic standards is required in each building. Without it, the air stagnates, changes its composition, enriched with harmful substances and dampness, as a result of which it becomes dangerous not only for people, but even for the building itself. The most important element of ventilation, in turn, are metal pipes for ventilation, which we will talk about in this article.

Material selection

In the ideal case, the ventilation should be arranged immediately when the box is erected vertically near the chimney. It is possible to use for this purpose brickwork or finished pipes, which is much more practical and easier.

General requirements for pipes

To date, for arranging ventilation ducts, plastic or metal products are commonly used, which, above all, should perform a number of mandatory functions:

| Function | Explanation |

| Absolute tightness | The presence of cracks, loose joints, holes will lead to the return of air masses removed from the room back, which will significantly reduce the efficiency of the entire system |

| Optimal performance | Through the pipe must pass freely given volumes of air for the required amount of time |

| Compliance with hygiene standards | The material must be environmentally friendly and not dangerous to human health. |

| Noise insulation | In fact, in the ventilation wind is formed, which, as you may know from your own observations, can be very loud, which will create discomfort for the tenants |

| Fire resistance | Fire safety instructions must be strictly followed. |

| Aesthetics | Must match the overall interior of the room. |

| Thermal insulation | Lack of heat loss significantly increases airflow strength. |

Tip: It is recommended to use pipes with a circular cross section for ventilation. Since the angles in the rectangular contribute to the creation of additional eddies that impede the movement of air.

Comparison of plastic and metal pipes

Metal and plastic are fully consistent with most of the requirements put forward above, but what is still better? Let's compare:

| Characteristic | Metal pipes | Plastic pipes |

| Weight | Large, as a result, the pipeline needs a reinforced fastening system | Small, so:

|

| Strength | High - able to withstand significant mechanical stress | Medium - PVC or HDPE products have sufficient reliability to withstand under the pressure of a strong wind at the outlet to the outside, but can be deformed as a result of a strong impact or physical pressure |

| Corrosion | Are subject to | Not subject to |

| Combustibility | Missing | Present |

| Processing complexity | Cutting is hard and with special tools. | Cutting is easy with simple tools available on the farm. |

| Bandwidth | Roughness is possible on the gland, which slightly complicates the passage of air. | Plastic is absolutely smooth and does not hinder the passage of air. |

| Price | Relatively high | Low |

Tip: if you plan to use metal products, it is recommended to purchase stainless steel or zinc coated pipes for this. Though they will come out more expensive, they will not be exposed to corrosion at the point of transition from the room to the outside, where there is abundant condensate sedimentation.

The remaining indicators for the considered products are about the same. It is also important to mention that both materials have rigid and flexible representatives. And if everything is roughly clear with rigid ones, then the flexible ones are corrugated sections of pipes, which make it convenient to bend round difficult sections when installing the pipeline.

It is clear from the table that it is difficult to say which pipe is better. Each has its own advantages and disadvantages. But it can be concluded that, due to low cost and ease of operation, plastic products are much more profitable to use in a private house, and in production, where durability and fire resistance become more important, metal samples will be more practical.

Installation Features

When arranging the ventilation duct in your house should consider a few important points:

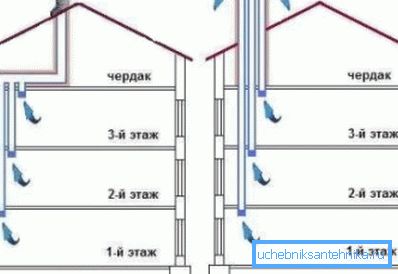

- It is desirable that the ventilation should be in every room or at least on every floor, and in particular this applies to the bathroom and kitchen.. In these rooms, the testing of air masses occurs at an increased rate.

- It is possible to lay a pipeline for each room separately with its own exit to the outside, but this will be inappropriate.. It is much more economical and practical to make one exit with the ventilation ducts connected to it.

- Place the outer part of the pipe in such a way that it exerts the least load from the wind.. To do this, you can hide it behind the ridge of the roof. So you not only protect the structure itself from possible deformations, but also prevent the backward blowing of the spent air masses.

- Before calculating the diameter of pipes needed for high-quality ventilation, it is necessary to take into account the volume of the room and its purpose.. But for residential buildings, 120 mm is usually quite enough, and you will most likely find products in the store with exactly this section.

- For fixing the connecting elements of the pipeline, use special clamps for ventilation pipes.

Conclusion

Ventilation is required for each room. For its implementation requires special pipes, which are usually made of plastic or metal. Above, we examined in detail their comparative characteristics and some nuances of installation.

The video in this article will acquaint you with additional materials. Choose pipes for ventilation rationally.