Pipes for wells: features of choice and installation

Suburban area needs uninterrupted water supply. It is necessary both for comfortable living of the tenants themselves, and for the ripening of the crop in their garden. In this case, the most rational method of extracting water is drilling and equipping a well, an important stage of which is the installation of pumping and casing pipes. About them and will be discussed in this article.

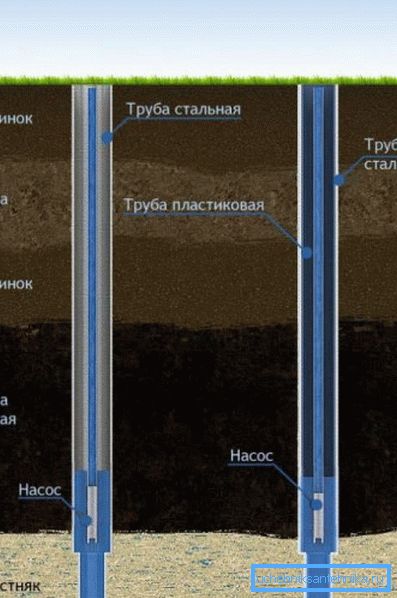

Selection and installation of casing

During the drilling process and after its completion, the well needs to be protected from the shedding of the soil. If this is not done, then sooner or later a collapse will occur and all your efforts will go to pieces. It is to prevent such disastrous consequences and installed casing, reliably propping up the earth walls.

Tip: before choosing a product, carefully review the properties of the soil and the characteristics of the installed water pumping station. This will allow you not to be mistaken with the material.

Let's see which pipe is better for the well:

Steel

Some time ago, steel occupied a leading position in the equipment of wells, but with the advent of plastic into life, the situation changed dramatically, visually highlighting the tangible flaws of metal products:

- High price.

- Exposure to corrosive processes.

It should not be forgotten that only iron structures are able to withstand any possible ground pressure during drilling. This property allows them to remain in demand.

Tip: when drilling artesian wells with a depth exceeding 65 m, it is recommended to use steel structures only. Only they will be able to withstand such strong loads of earth layers.

Asbestos cement

These products are also time tested and are distinguished by the following positives:

- Low cost.

- Long operational life.

But there are also negative points:

- The relative fragility, which greatly complicates the installation work with their own hands.

- The need to drill larger holes due to the thick walls of the asbestos-cement pipe.

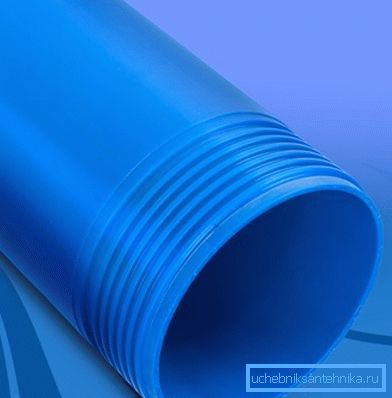

Plastic

Polymers are widely distributed relatively recently, but have already established themselves with their unique technical characteristics:

- Corrosion Resistance.

- Full hygiene.

- Chemical inertness.

- Low price.

- Excellent tightness of connecting nodes.

- Little weight.

- Long service life, over 50 years old.

- Simple installation instructions.

The disadvantage is to include only susceptibility to mechanical stress, which must be taken into account when choosing this product. (See also the article Plastic sewers: features.)

Plastic pipes, in turn, are divided into PVC and polyethylene, the differences between which should also be aware of:

| Material name | Pipe abbreviation | Technical properties |

| Low-pressure polyethylene | HDPE |

|

| Polyvinyl chloride | PVC |

|

As you can see, low-pressure polyethylene products are much more practical than PVC pipes. It is noteworthy that this also applies to the pipe that is connected to the pump for lifting water.

Installation

Regardless of the material chosen, the installation of the pipe has several important nuances:

- After you have drilled a few meters of the well, it is time to lower the first section of the structure. Further drilling should continue inside it to avoid collapse.

- Lower the remaining pipes as they are immersed. To hammer them, use wooden males or special extensions so as not to damage the edges of the product.

- After water appears, siphon the mule and pour some gravel to form a bottom filter. (See also the article Sewage system: features.)

Tip: it is recommended to make holes on the sides of the first-meter pipe. This will increase the productivity of the well.

Water lifting pipe

We have already figured out the advantages of pipes made of low-density polyethylene, so we will not return to this issue, but rather consider some of the features of their installation, together with a submersible pump:

- Level, lay out on a flat surface and connect all necessary elements to the water-lifting equipment:

| Title | Special features |

| HDPE pipe |

|

| Power cable |

|

| Cable |

|

- We fasten into a single tire.

- We lower the pump into the casing, holding the cable. If the movement begins to stop, then scroll through it, continuing to press.

- After the dive we set the tips on the surface and use the well.

How to get pipes from a well in case of breakage of water-lifting equipment or to carry out maintenance work? To do this, simply remove the tip and gently pull the entire structure over the cable. After that, as well as during installation, decompose for a thorough inspection.

If the groundwater is located close to the surface at a distance of 5-7 m, then an excellent solution would be to create an Abyssinian well, which does not need a casing structure, but immediately “pierces” the soil with a water lift.

Conclusion

The working well is necessary on each country site. Its arrangement does not do without use of pipes. They are needed both to protect the structure from earthen collapse, and to deliver water to the surface.

The video in this article will introduce you to more information. Successful to you well arrangement!