Pipes in the bathroom - design and installation features

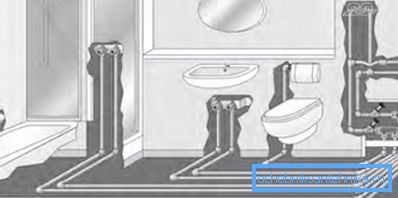

Laying pipes in the bathroom - a responsible event, which should be taken very seriously, especially if you do all the work with your own hands. The reliability of the system and its durability depend on the correctness of the project and the thoroughness of the installation; this is especially important if pipes run inside walls or be poured into the floor, because to eliminate the leakage, you will have to carry out a whole range of works.

Bathroom tubing options

Pipes for a bathroom are produced from a variety of materials, we consider the advantages and disadvantages of the most widely used solutions:

| Metal | Steel pipes for several decades were the only option. They are distinguished by labor-intensive installation (most often welding equipment is needed), while the price of products is very high. In addition, the metal is susceptible to corrosion, which is a huge disadvantage in conditions of constant dampness. |

| Polyethylene | This material is distinguished by a rather high strength and impressive elasticity indicators, due to which the pipes from it, even when freezing, most often preserve integrity, but are afraid of high temperatures - from them they are deformed |

| PVC (polyvinyl chloride) | An excellent solution for an open version of communications. During installation, a variety of solutions can be used: welding, glue, special fittings, everything depends on the specific conditions and characteristics of a particular object. |

| Polypropylene | Without a doubt, the most popular and popular option today. Not only water pipes, but also sewage pipes, as well as products for heating systems are made of polypropylene. It is easy and convenient to work with this type of materials, wiring pipes in the bathroom can be done independently. |

How to build a workflow

It is very important to draw up a clear plan of action so that work moves quickly without delays and downtime. All communications must be assembled in compliance with the technology, the only way to ensure their reliability and durability.

Preparatory stage

Long before the start of work it is necessary to carry out a number of activities. Their list depends on the features of the object, for example, if the replacement of pipes in the bathroom is done, then it is necessary to provide for dismantling the old system. At new facilities, everything is much simpler, because nothing needs to be dismantled.

First of all, a project of future communications is being developed, the main thing is to foresee all the nuances:

- It is very important to determine the exact location of all elements of the system, the amount of necessary materials and used components depend on it.

- Next, you need to decide which method of laying will be used: the open version is simpler in execution, but the closed version looks much better, because communications are not at all visible.

- The next important part of the measures is the determination of the optimal diameters of all the pipes to be used. This indicator depends on the number of sanitary equipment and estimated water consumption.

Tip! It is very important to carefully check the correctness of the project, it is best to attract a qualified specialist for this, it guarantees that all calculations and location will comply with the established norms and standards.

Next, you need to purchase everything you need for the work, and you should not forget about the working tool.

In addition to materials and fittings, you will need the following accessories:

- A special device for heating and soldering elements among themselves.

- Scissors for cutting pipes.

- A knife for stripping pipes.

- Measuring tape and marking marker.

System installation

It can be divided into two large stages, each of which is done separately.

Most often, the first installation of sewer pipes in the bathroom, the workflow is as follows:

- First, careful measurements of all sections of the system are carried out in order to calculate the slopes, which should be 2 cm per linear meter with a pipe diameter of 110 mm and 3 cm per meter with a diameter of 50 mm.

- If old cast iron pipes are replaced, then a new part of the riser is often installed, so that the connection between plastic and cast iron is reliable, it is necessary to purchase special adapters.

Remember! When assembling the system in a private house, it is necessary to provide for ventilation of the sewage system, for which a separate duct is brought to the roof and is not connected to the ventilation system.

- Particular attention should be paid to the installation of the riser, it should be located exactly, without any distortions and slopes.

- It is also important to carefully fix all the elements in a stationary state so that the slopes are uniform, without drops and do not move during the work, as this significantly increases the likelihood of blockages.

Then you can begin to assemble the plumbing system, the installation of pipes in the bathroom is as follows:

- When deciding how to hide the pipelines, you can choose one of the following options: wall chipping to the size of the communications or installing the box after the system is assembled.

- Next, the pipes are cut into pieces of the right size, it is important that the ends of the elements do not have scuffing and are dry and clean.

- Soldering is carried out according to the instructions, the pipes and fittings are put on the fittings and are kept for the required time, after which they are removed, carefully combined and strongly pressed against each other for a few seconds. Full freezing occurs within a minute.

- At the entrance to the system, a tap must be installed so that in case of accidents and when servicing the system it is possible to turn off the water. It is also desirable to put on the input filter for water purification.

- After completion of work, all pipelines are thoroughly checked, for this the system is filled with water, and the connections are inspected for leaks.

- If the pipes are to be closed with a duct, then after the assembly of the system, a frame made of metal profile is installed, which is sheathed with gypsum-fiber sheets or moisture-resistant gypsum board.

Conclusion

When working on the installation of pipes in the bathroom, the most important thing is the use of high-quality materials and compliance with the technological process. This is the only way to guarantee the reliability of the system.

The video in this article will help to understand the question even better.