Plastic pipe connection without soldering machine

When arranging communication systems, it is necessary to dock out the individual elements, however this process can be performed in completely different ways. Special attention is given to the connection of plastic pipes without soldering, because in this case it is possible to do without the use of a special apparatus, the price of which is quite high.

Docking with fittings

In this embodiment, a set of shaped parts is used, allowing the combination of not only two, but more elements. Learn how to connect plastic pipes in this way wants every developer who does not have at his disposal an apparatus for soldering.

Advantages of the method

- The low cost of fittings allows you to reduce the cost of summarizing communications.

- Easy installation allows docking even for non-professionals.

- The ability to use parts in systems with pressure head expands the scope of application.

Note! It should be borne in mind that this method is applicable to elements with a small diameter, and in other situations it is often used that it is connected with thermal effects.

Work

The time has come to understand how plastic pipes are connected directly by compression fittings. From the tools you will need: a sharp knife for cutting elements, a calibrator, as well as manual or automatic tongs for the clamping operation.

First of all, cutting is performed on the components of the communication system, if this is required in a particular case. The incision should be made strictly perpendicular, so as not to form bevels and other flaws. After that, the calibrator eliminates ovality at the junction.

Then a special coupling is put in, and the fitting itself with sealing rings is inserted into the pipe. Top is crimping cooked tongs. Thus, it is possible to connect plastic elements.

However, in some cases it is required to learn how to connect a plastic pipe with a cast-iron pipe. For this purpose, a special adapter is used, the diameter of the sides of which corresponds to the dimensions of the pipes used. In the process of joining it is necessary to remember that the coefficients of linear expansion of plastic and cast iron are noticeably different.

Bonding of individual elements

In addition to the above options, there are other ways to connect plastic pipes. One of those is the process of bonding, when the ends of the component parts are joined using a special chemical composition. During the work it is possible to ensure sufficient tightness.

The principle of the composition

Glue intended for plastic products usually contains polyvinyl chloride, which dissolves in methyl ethyl ketone, tetrahydrofuran and cyclohexanone. In the two-component compositions are also added special additives that improve adhesion.

Advantages of the adhesive method

- Quality grip chemical means with surfaces of elements allows to receive high tightness.

- Availability the main material makes it possible to apply it to a wide range of consumers.

- Invisibility of the joint It has a positive effect on the aesthetic perception of the components of the communication system.

Attention! The glue used should be stored well away from an open flame, as it is easy to catch fire. In addition, when working it is necessary to protect the skin from the ingress of the substance.

Composition

You can make bonding with your own hands. Works should be carried out at a temperature of from +5 to +35 degrees. In advance, you need to prepare a brush with natural bristles. In most cases, it comes directly from the adhesive composition.

Before starting the main steps, it is advisable to assemble the structure without the use of a chemical agent in order to perform a preliminary fitting. Before applying the substance, it is necessary to degrease the surface using solvents.

A thin layer of glue is applied to the prepared surfaces. The plastic product is inserted into the hole until it stops; in this case, it is necessary to avoid rotation or other manipulations. For 15–20 seconds, the components are held together so that the adhesive has time to dry.

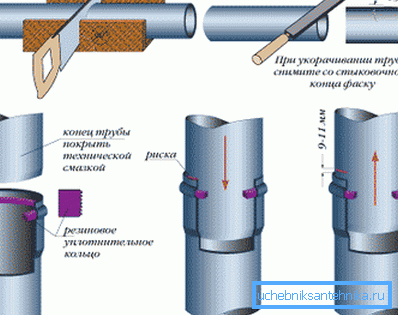

Bell flush

The presented method is applicable mainly for sewer systems, as they do not create pressure. At the ends of the elements used there are special connections for plastic pipes - sockets. With their help, the fixation itself is made.

Positive aspects of technology

- Relatively high assembly speed ensures installation in the shortest possible time.

- The absence of the need to purchase additional components reduces costs.

- The possibility of self-assembly allows you to refuse professional help.

Note! For non-pressure systems, this option can be considered quite tight, because when installed, a rubber gasket is inserted inside, which at the same time makes it possible to compensate for the discrepancy between the parts to be connected.

Description of the assembly process

Making sure before mounting that there is a rubber ring in the socket, you need to clean it of various impurities, then you will be able to achieve good adhesion. Grease must be applied to the smooth edge of the pipe to improve sealing. After this is done docking.

To do this, the smooth end of the element is inserted inside the socket to the stop. The point of contact with the edge is marked with a marker to make it easier to determine the distance to the dock. Next, the product is pulled back about 10 mm directly from the dash.

The gap is made to compensate for linear expansion, which usually occurs during temperature fluctuations. In this regard, it will be possible to avoid the appearance of internal stresses in the communication network.

The cutting of the system components is strictly perpendicular to eliminate the possibility of pipeline bending. After cutting from the face, the chamfer is removed using a regular file. This reduces the likelihood of damage to the gasket.

Final part

After considering this topic, almost every newcomer should qualitatively make the connection of plastic pipes without any help. Additionally attached visual instruction that will help to understand the difficult points associated with the installation work.

Also the video in this article will be useful.