Plastic pipes: complete information on their types,

Now plastic pipes have an extensive scope of use. They are most popular for the installation of a variety of engineering networks. Plastic, polymer - these are common names, so you should talk about products from it in detail.

Production of plastic products

First, the advantages of polymer pipes.

Product advantages

- They are not subject to corrosion.

- Hydraulic resistance in them does not increase over time.

- Head loss due to friction is less by one third than in metal counterparts.

- Frost resistance, preservation of plasticity at low temperatures.

- Low specific weight.

- Excellent bandwidth.

- Low thermal conductivity.

- The material is a dielectric.

- Simplicity of assembly of systems from such pipes.

Field of use

- Systems of drinking, domestic and hot water.

- Transportation of technical and chemical liquids.

- Delivery / supply of flammable gases.

- Heating systems.

- Sewerage and drainage.

- Such pipes can be used as protective channels for electrical wires and communication cables.

Varieties of plastic

Among the polymer products distinguish pipes of thermoplastics and thermosets. Below is a table of these materials.

| Thermoplastics | Reactants |

| polyethylene (PE) | fiberglass |

| polyvinyl chloride (PVC) | fiberglass |

| polypropylene (PP) | epoxy resin |

| polyamide (PA) | polyester resin |

| polybutylene (PB) |

Plastic consists of carbon extracted from gas and oil. During processing, this low molecular weight substance undergoes polymerization.

As a result, new materials are created, the number of bonds between their molecules is greater.

- Thermoplastic consists of homogeneous (linear bond) molecules. If the material is heated, it becomes soft, while cooling the plastic will restore the initial structure. The instruction warns that the softening temperature of the material is low (from 60 °), therefore the scope of use of thermoplastics is limited.

- Reactoplast has a composite structure (spatial connection). It is chemically non-uniform and undergoes additional processing during production. As a result, the material molecules form three-dimensional additional bonds.

Note! Reactor plastics are more thermally resistant. However, if the temperature threshold is exceeded, they are destroyed. Thermoplastic is less fragile, internal connections are preserved when it is fully melted.

Main technical specifications

One of the main characteristics of pipes is the diameter.

Overall parameters

Below is a table regarding pipe diameters.

| Designation | Decryption | Characteristic |

| Dn fittings | nominal diameter | the main overall parameter of pipes and |

| ID (DN) passageway | conditional diameter | internal diameter in mm |

| OD (D) | external diameter | outer diameter in mm |

| En | pipe wall thickness | |

| SDR standard dimensional relation (Standart Dimension Ratio) | divided by Dn by En (SDR = Dn: En) |

Strength properties

Strength properties

- The density of the material.

- Nominal pressure (PN) is the pressure level (nominal) that the pipe can withstand.

- Minimum Required Strength (MRS) - long-term strength (minimum) material.

- “C” is the safety factor. It depends on the installation conditions of the system. The coefficient of 1.25 have plastic pipes for plumbing. The value of 2 / 3.15 is taken for gas analogues.

- Maximum Operation Pressure (MOP) is the operating pressure (maximum). Calculated using the formula 2 • MRS: C • (SDR-1).

- Ring stiffness (SN), in kN / m2.

- Stretch yield strength, in MPa.

- Elongation (relative) at tearing, in%.

- The change in the length of the product after it is heated, in%.

- Thermal stability of products implies their resistance to maximum and minimum temperatures, as well as the working value of this parameter.

- Resistance to slow and fast cracking.

- Impact strength.

Features of various plastics

- PVC pipes can retain their original shape even when heated to + 85 °. They are well amenable to welding, have the lowest coefficient of linear expansion (at a temperature of + 60 °). Used in sewer, cold water, ventilation systems.

Note! Usually, PVC pipe systems are assembled using cold welding. You can mount them hidden or external method.

- PP pipes are used for cold and hot water systems, air duct assembly. They can be used at a temperature of the transported substance up to + 95 °. The term of operation is up to 50 years.

Welding of plastic pipes of this type is carried out by the diffusion method. It is simple, the process takes only a few minutes, and the joints have high tightness.

- PE pipes are used at a low temperature of the transported substance. They are suitable for external systems of water and gas supply, as well as networks that deliver technical liquid and gaseous substances. Polyethylene can retain its structure at ambient temperature and transported substance at -20 ° / + 40 °.

Connect the PE pipe, with a cross section of less than 63 mm, using electrofusion couplings, brass or PP fittings. Plastic pipes of large diameter (over 63 mm) are mated by butt welding. Analogs of cross-linked polyethylene are joined by cold pressing (permanent connection).

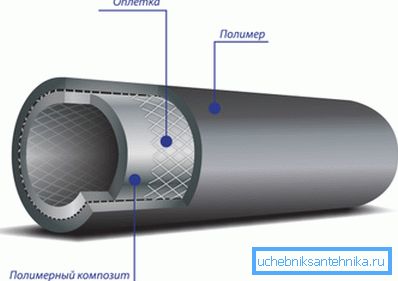

- Metal-plastic analogues have a three-layer structure. In them between the outer and inner layers of the polymer is a foil of aluminum. It protects the material from oxygen leakage and reduces its linear thermal expansion.

Systems of such elements are assembled using press fittings and compression analogues. Let's apply metallayer in heating and pressure head pipelines. It can withstand the temperature of the working substance up to + 95 ° continuously and up to 110 ° for a short time.

Practical use of plastic pipes

Many engineering communications are now assembled from plastic, not metal.

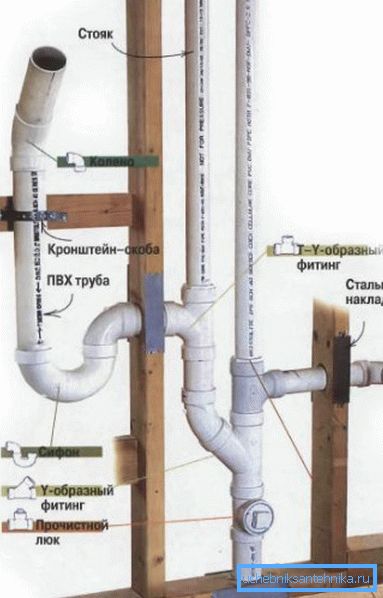

Sewage

PVC pipes have good resistance to aggressive sewage. Operating the system is easy.

If it becomes clogged, you can disassemble the area and clean it.

Note! To prevent problems: leaks, blockages, depressurization, choose quality products. Plastic sewer pipes must be completely smooth, without cracks, blisters and burrs.

- Produced products have a different cross section. Pick it up, starting from the load on the system.

- For apartment buildings and small public buildings, 110 mm diameter trunk pipes should be chosen. In large medical and educational institutions, hotels, analogs with a cross section of 200 mm are used. At industrial facilities - 300 mm.

- For cottages, houses and cottages for one family fit pipes having a diameter of 50 mm.

Assembling a plastic pipeline for sewage is extremely simple. It is only necessary to insert one element into the socket of the other with a rubber sealing ring. It is not necessary to mint and gloss over the joints.

Note! When the smooth end is not inserted into the socket, heat it over the gas stove or brush it with a solution of soap. Do not overheat or melt the plastic.

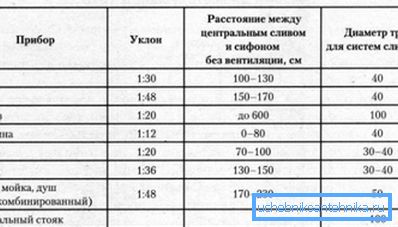

When assembling the sewage with your own hands in your own home, consider the slope of the pipeline and the depth of its foundation.

- Slope depends on the ability of the system to self-cleaning and the flow rate of the fluid. For general sewer networks, if the flow velocity is optimal (0.7 / 1 m / s), the slope is 1 cm per 1 m of the length of the system.

- The recommended level of pipe laying is 0.7 / 0.9 m at the house exit with subsequent deepening in the direction of inclination (not less than 1 meter to the entrance of a septic tank, cesspool or well).

Water pipes

For plumbing, you can use pipes from different types of plastic.

- Polyethylene analogues (international designation PE) hold a working pressure of 6/10 kgf / cm ?. The minimum temperature of their operation is -20 °. Therefore, the products can be used for both external and internal parts of the water supply system.

- Products made of cross-linked polyethylene (PEX) has high strength and improved temperature properties.

- PVC analogues have high working qualities, their price is relatively low.

- Aluminum-plastic pipes (PEX / AL / PEX) hold pressure levels up to 10 bar. Suitable for arranging hot water, because maintain temperature at + 95 °.

The main condition for the installation of a plastic pipeline is to use short nodes with increased rigidity at the minimum. The system must be as flexible as possible. A small number of compounds reduces the risk of leakage.

Fix pipes from plastic to the base should be clips and movable supports.

When mating metal and plastic elements, detachable fittings are used, having metal inserts inside.

Ventilation, gas supply and heating

When assembling a heating system, plastic elements have several advantages.

- They serve up to 50 years, while not corroding.

- Due to the smoothness of the inner walls, the pipeline does not make any noise when the coolant flows through it.

- The system does not settle limescale.

- Plastic has a low thermal conductivity, so the media cools in it more slowly than in metal.

- The material is resistant to temperature changes and hydraulic shocks.

Aluminum, PE, PVC, PP pipes are suitable for heating systems. The last analogues over time can lose their original form, since have high fluidity. Based on this, the PP pipes should be attached more frequently.

Heating plastic pipelines are mated with fittings or soldering. In order not to spoil the wall covering, you need to put on the system a sufficient number of compensators.

Recently, polyethylene pipes have been used for gas pipelines.

- They have a high level of resistance to external and chemical influences.

- Such products are plastic and at the same time durable. Their installation is convenient and possible in areas with harsh climates.

- Plastic products do not need additional protection before laying it in the ground, because resistant to electrochemical effects.

- Plastic is used only for underground installation. Entry into the building and internal wiring of the gas network is made using metal pipes.

Note! The use of PE pipes for gas pipeline systems is prohibited in regions where the winter temperature reaches -45 ° or seismic activity can exceed 6 points. They can not be used for the transportation of combustible gases in high-pressure systems (I and II category).

Another niche for the use of plastic products is the ventilation system. They guarantee the reliability of the engineering network and have a long service life. When installing the system near the ventilation outlet, the main pipe is mounted. From her divorced other elements, usually with a diameter of 100/160 mm.

Often, to prevent the appearance of an unpleasant smell, such a duct is equipped with a fan. That is, forced ventilation is created, which ensures maximum air exchange rate.

Conclusion

Plastic pipes for sewage, water and gas pipeline systems, ventilation have a variety of characteristics. Therefore, you can easily select products that are best suited for your operating conditions. The video in this article will complement its information.