Plastic pipes for heating - features, types and methods of

Today, when organizing communication systems, plastic pipes are used much more often than cast-iron or steel pipes. But when faced with their diversity, questions arise which plastic pipes are better for heating, which features are characteristic of these products, etc. In this article, we will look at their characteristics, application and much more.

A variety of plastic pipes

Given the fact that all heating products made of plastic include a reinforced element, depending on the type of reinforcement there are the following types:

- Plastic products with aluminum reinforcement. They are reinforced with a sheet of aluminum, either from the outside or towards the middle.

- Pipes that are reinforced with fiberglass material. Fiberglass is placed between the outer and inner layers of the pipe.

- Reinforcement with composite materials. In this case, it is reinforced with a composite consisting of polypropylene and fiberglass.

Characteristics of polypropylene products

Polypropylene pipes are a great alternative to cast iron and steel products.

The technical characteristics of plastic pipes for heating provide them with the following advantages:

- Increased wear resistance, which allows the use of polypropylene materials to supply hot and cold water.

- Low weight, allowing easy transport to the installation site.

- Simple installation process that allows you to organize heating from plastic pipes with your own hands.

- No special service required.

- It is worth paying attention to the fact that they prevent the growth of bacteria and the formation of deposits.

- There is no release of any harmful substance, no impact on water quality.

- This type of material does not need painting.

- Low hydraulic resistance prevents vibrations from moving water.

- Also, plastic products are resistant to chemical and mechanical stress.

- The material used in the production process is highly flammable and can work at ambient temperatures of up to 120 degrees.

Note! The deformation (softening) of the plastic structure occurs at temperatures from 130 degrees, and melting occurs in excess of 150 degrees.

- They cope with a strong water pressure.

In general, the advantages of such products are many, the low price and the guarantee that they will last 50 years, make it possible to make a choice in favor of the material described by us.

Where are plastic pipes used

The versatility of polypropylene materials causes their use in many areas:

- Hot and cold water supply system.

- Boiler installations.

- Organization risers.

- Under floor heating systems.

- For the discharge of waste water and irrigation systems in the field of agriculture.

- For the organization of transportation of chemical liquids in the field of industry.

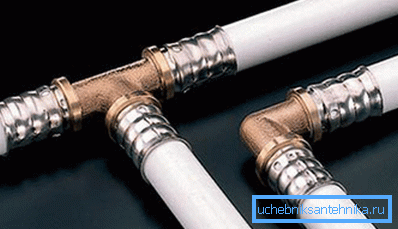

Fitting for polypropylene pipe

In order to make the connection of polypropylene pipe products, special parts are needed. Plastic heating pipes and fittings create a single system, ensuring the perfect fit of all parts, therefore, in addition to the choice of these materials, it is important to choose the right fitting.

Note! For plastic compounds used fittings, which are mounted by soldering. But there are others that are threaded, such fittings are able to connect products of various materials.

Select fittings for polypropylene pipes, you need to be guided by the types of products used in the device of the heating system, as well as the conditions in which the heating system will be used.

Polypropylene pipes of different diameters

The diameters of plastic pipes for heating are important parameters for organizing pipelines. After conducting hydrodynamic calculations and drawing a diagram of the heating system, you can select the desired diameter of the products in each particular installation location.

Here are some examples of using different diameters:

- Large sizes, more than 20 cm, are used in buildings designed for high maneuverability - in hospitals, shops, hotels and etc.

- A diameter of 2-3 cm is used for the construction of country houses. Such materials have high throughput and it is easy for them to give any shape.

- When organizing a riser, a diameter of 2.5 cm is used.. The same indicator is relevant for central heating systems.

- Instructions for arranging the system of warm floors advises to choose small diameters - not more than 1.5 cm.

We mount pipes from polypropylene

The work on the organization of the heating system is quite simple, the main thing is to take into account a few simple recommendations and requirements:

- Do not work at low temperatures.

- All materials must be cleaned and inspected for damage.

- Soldering of plastic heating pipes should be carried out only with a special tool.

- It is unacceptable to do the threads on PVC pipes.

- The use of special scissors (cutter) is necessary in order to accurately cut the product.

Tip! If you do not have special scissors on hand, you can use a hacksaw or jigsaw. The main thing, after cutting, carefully clean the cut and sand it from burrs.

The main stages in the device of the heating system of plastic products can be considered the following:

- Having calculated what sizes of plastic pipes for heating we need, we make a marking and cutting of details.

- We note the depth at which the fitting is immersed, we note this distance from the cut.

- Also note the places where parts and fittings are connected.

- We carry out heating of both parts with a special apparatus.

- Then we connect both parts according to the markup.

- During the cooling of the docking seam it is possible to slightly adjust the quality of the connection.

Conclusion

We considered all the features that have plastic pipes for heating, as well as important points of the workflow. After installation, check the quality of the connections and, in case of leakage, use sealants to eliminate poor quality joints.

We hope that the above information will be useful and will help determine the appropriate elements of the heating system. In the presented video in this article you will find additional information on this topic.