Plastic pipes for heating: variations, characteristics,

Heating with plastic pipes has long ceased to be a subject of controversy: most experts recognize their efficiency and reliability, and European countries are actively switching to this material. Good technical characteristics, easy installation, long service life and safety have made plastic pipes for heating one of the most popular sanitary materials in our country and abroad.

Polymer pipes for heating systems

General features

Plastic pipes for heating are a whole class of sanitary equipment, which includes products made of various materials and their combinations, and for each such material there are a number of characteristic differences that relate to operating conditions, installation rules and technical nuances.

At the same time, this class has many common features, and in order not to repeat, we will first consider the general points, and then we will talk about the individual representatives and their characteristics.

Plastic pipe for heating is a product from polymeric raw materials, most often polypropylene and polyethylene with various inclusions are used, some types of polyvinyl chloride and polybutylene are also sometimes used, but their market share is insignificant.

These polymers determine the basic properties of the products made from them:

- The low density of plastics has led to a significant reduction in pipeline weight.. As a result, the cost of transportation and installation of equipment has decreased, in addition, the requirements for fixing fittings and the bearing capacity of walls are also significantly simplified;

- The cost of production of polymeric goods is much lower than the cost of rolled metal, which could not affect the prices of the final product. The exceptions are the most advanced technologies of high quality, such as PE-X - Al - PE-X and PERT - Al - PERT;

- Installation of heating with plastic pipes is simpler and cheaper than installation of rolled steel. To master the work with a tool for soldering or pressing in plastic can almost anyone in a short time;

- Polymers are not afraid of exposure to moisture and oxygen., they do not corrode and do not deteriorate as a result of the activity of bacteria and other pests;

- Roughness of walls is significantly reduced compared to metal, therefore, the pipes practically do not overgrow with salt deposits, silt and other substances;

- The ductility of the material allows the pipes to withstand hydraulic shocks and freezing the coolant;

- Repair of plastic heating pipes is much easier and faster..

Note! These features are valid only for high-quality materials produced from good raw materials in compliance with the technology. The modern market is full of fakes and just low-quality cheap goods.

It is considered to be that plastic cannot normally be operated in the conditions of high temperatures because of thermal expansion and fusibility. However, today these problems are solved with the help of reinforcement and the use of modern materials.

Polypropylene

Polypropylene has the largest market share in Russia. This is due to its cheapness and affordability, as well as the successful marketing policy of manufacturers and sellers.

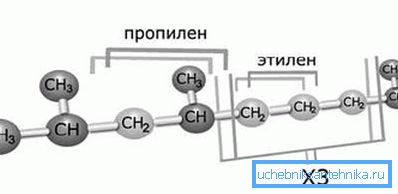

Pure propylene products (PP-R marking) are not used for heating due to the high thermal expansion coefficient. However, reinforced pipes can be used for hot water, especially since modern products are made from random copolymer (PPRC), which can withstand extreme conditions much better.

Reinforcement is made by two materials: aluminum and fiberglass.

Thus, we can select plastic and fiberglass pipes for heating, the characteristics of which are listed:

- Nominal pressure can be up to 2.5 MPa or 24 atm .;

- Maximum working temperature - not more than 95 ° C, nominal temperature - 70 ° C. Short-term jumps up to 110 ° C are possible;

- The density of the material according to GOST 15139 is 0.9 g / cm3;

- Thermal expansion coefficient - 0.15 mm / m * ° C;

- The tensile strength is 34 - 35 N / mm2.

Polypropylene is characterized by the general advantages of the plastics listed above, and also it is distinguished by monolithic compounds and rather high impact strength.

You can also highlight the ability of a material to withstand pressure and temperature drops, good noise absorption and thermal insulation, but at the same time low price remains the main and most significant advantage.

Soldering plastic pipes made of PPRC is much simpler and cheaper than arc or argon welding of metals, but it still depends heavily on the skill of the installer. In more modern systems, the human factor is practically excluded.

Among the shortcomings mentioned are the fear of low temperatures and the low reliability of the systems. After a few years of operation, the connections may start to leak, although it is difficult to specify the reason: the level of most domestic installers is frankly lame.

Note! One should also recall such a feature as the impossibility of pipe bending, which leads to a huge number of connections with swivel couplings.

Polyethylene

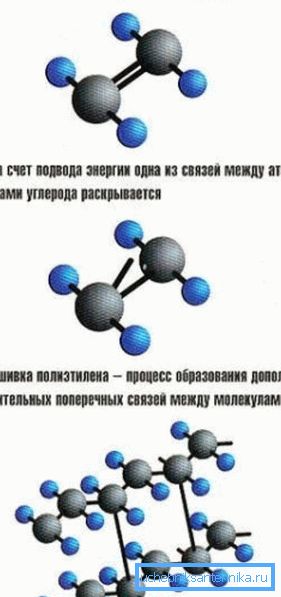

Recently, another type of plastic is actively gaining popularity - cross-linked polyethylene. This material is characterized by increased heat resistance, durability and excellent technical qualities. The most common type is PE-Xa; sometimes they produce compositions with an inner layer of PE-Xc to increase strength.

In heating systems, you can use several types of polyethylene:

- Pure PE-Xa polyethylene with a layer of ethylene vinyl alcohol that prevents diffusion of oxygen into the pipeline. The most popular brand is Rehau Raupink;

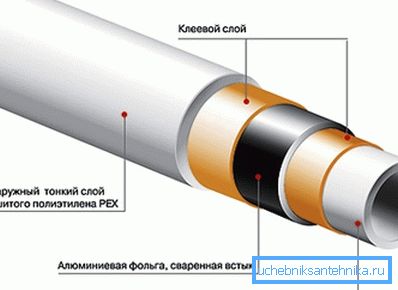

- The combined polyethylene reinforced by aluminum. Structure - PE-Xc - Al - PE-Xa;

- Aluminum-reinforced PERT-Al-PERT polyethylene is the most promising material, but at the moment its use is justified only in low-temperature heating systems.

The most reliable and proven are reinforced composite pipes.

For these products such characteristics are relevant:

- Nominal pressure - up to 10 atm .;

- Maximum working temperature - no more than 90 ° C, nominal temperature - 70 ° C. Short-term jumps up to 100 ° C are possible;

- The maximum pressure of pressure testing at a temperature of 0 - 25 ° C is 25 atm .;

- Guaranteed service life - at least 50 years.

Note! Cross-linked polyethylene is objectively more reliable and stronger than polypropylene. In addition, the installation of systems with their own hands simplified as much as possible, and the human factor is minimized.

Installation

As an example, we consider the technology of bell-shaped soldering of polypropylene:

- The end of the pipe must be cut at an angle of 90 degrees with a sharp knife or a special pipe cutter;

- If there is a surface reinforcement, it should be cleaned with a shaver, and also chamfered at an angle of 45 degrees to two-thirds of the wall thickness;

- On the soldering iron, you need to set the temperature to 260 ° C, then put on the coupling for connecting the pipes to the appropriate nozzle, and insert the end of the pipe into the Teflon head. The heating time depends on the diameter and wall thickness, it is indicated in the instructions or special tables;

- After heating, it is necessary to quickly insert the end into the clutch and press it against the stop, but do not press further;

- In conclusion, the parts to be joined should be kept stationary until the polymer hardens - about 2 minutes.

Note! The stated properties of this pipe connection are valid only in the case of using professional tools and strict adherence to technology.

Conclusion

Polymer pipes have proved to be a good replacement for metal in the heating systems of apartments and private households. The most reliable products are made of cross-linked polyethylene, reinforced with aluminum. The video will help you to better master the technology of installation work and prevent mistakes.