Plastic pipes for ventilation: features of choice and

Despite the fact that many compatriots in the arrangement of air exchange schemes in residential buildings use improvised materials, there is a category of products specifically designed for the arrangement of ventilation systems. In this article we will talk about how to choose plastic pipes for ventilation and how to install them.

The advantages of these products

The advantages of special plastic ducts include such qualities as:

- standardized sizes and cross-section configuration with supply and exhaust fan units or recovery units;

- low weight and, as a result, a small load on fasteners and on the surface on which the installation was carried out;

- absolute corrosion resistance;

- higher tightness of the connection in comparison with the connection of metal ducts;

- lower operating noise;

- ideally smooth internal surface and as a result a small amount of pollution;

- easy mechanical cleaning of the system with minimal use of chemicals;

- esthetic appearance;

- durability.

After we have decided on the characteristic advantages, we will consider where plastic ventilation pipes are used.

Application features

Speaking about the features of the use of polymer ducts, it is necessary to note that they have one major drawback, namely, they are unstable to high temperatures.

Perhaps this is the only limitation that determines the scope of application of polymer products. As a result, a plastic ventilation pipe of 100 mm or analogs with a different diameter can be used as any air ducts in household systems, but cannot be used to divert exhaust gases from heating equipment.

In addition, polymeric air ducts are not used in the device ventilation systems in production. When productivity is required from a ready-made system by industrial standards, metal channels are used instead of plastic structures.

Instructions for the use of plastic pipes does not imply their use in the arrangement of saunas, baths and steam rooms.

Important: The high temperature characteristic of such premises can lead to deformation of polymer products. Moreover, some types of polymeric materials with strong heat can release potentially unsafe substances into the environment. That is why in the saunas and baths the air ducts are made of sheet steel.

Polymer Duct Types

At present, polymer ventilation ducts are represented by various modifications, which differ in the type of materials used in the production, cross-sectional configuration, frame sizes, installation features and manufacturer's brand.

Consider these types in more detail:

- According to the type of production material, the pipes differ from:

- polyvinyl chloride (PVC);

- polyurethane (PU);

- polypropylene (PP).

Of all the modifications listed, PVC ventilation pipes are the most popular. The relevance of these products largely explains the reliability, durability and, most importantly, reasonable price, compared to the cost of other polymer products.

Pipes made of polyurethane are rarely used today, since the cost of production of such products is high. In addition, PU air ducts are characterized by an insufficiently smooth inner surface, which may serve as a reason for the formation of operational blockages.

Polypropylene air ducts are not much inferior to PVC products, but their price is slightly higher, and, in addition, to ensure the proper strength of the PP, products must have a greater wall thickness than PVC analogues.

- In accordance with the configuration of the cross section, round and rectangular products are distinguished.

Immediately, we note that the cross section configuration in no way affects the performance of the channel. The only criterion for choosing the configuration is the design features of the hoods and blowers.

In addition, when choosing the configuration of the cross section, you can be guided by aesthetic preferences. For example, it is no secret that the square channel fits perfectly into the angle between the wall and the ceiling, whereas it is better to hide the round pipe in a special box.

- In accordance with the standard sizes, air ducts are divided into those products that are suitable and those that are not suitable for the implementation of a particular ventilation scheme in the house. First of all, attention is paid to the diameter of the cross section, if the pipe is round (the required values are 55-110 mm). If the duct is rectangular, the aspect ratio of the cross section is taken into account. Choosing the size of plastic pipes for ventilation, you need to take into account the parameters of the hood or other equipment to which the pipe will be attached. The length of the channel (the required sizes of 0.5 to 1.5 m) is a less important parameter, since polymeric products can be cut if necessary.

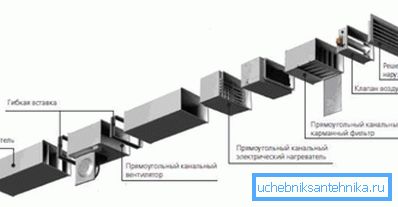

Important: When choosing a duct, you need to understand that buying one plastic duct is not enough and you will need special ventilation connectors, taps, adapters, if different cross-sectional configurations are used, etc.

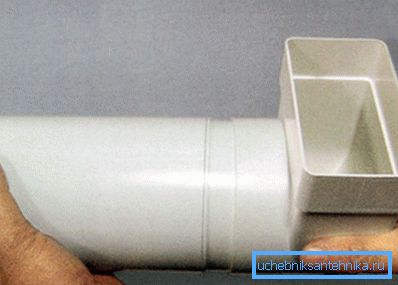

- Manual installation of plastic pipes with their own hands involves the use of special connecting elements, the inner surface of which corresponds to the size of the outer surface of the duct. Thus, the pipe as in a case moves in a connecting element and is reliably fixed in it, providing due degree of tightness. One more kind of assembly connection - bell-shaped. One end of the tube is wider than the other. The narrow end is inserted into the wide and fixed there by a thread or rubber seal. A similar type of connection is found when installing drainage pipes when assembling a sewer.

Important: Choosing one or another type of connection, we give preference to those air ducts that correspond to the type of connection provided for the ventilation equipment used.

Conclusion

Of course, in a country house can be collected ventilation from sewer plastic pipes. But only the use of special ventilation channels allows you to build a system that will not only work well, but also look good.

Have any questions? You will find more useful information by watching the video in this article.