Plastic pipes for water supply: types and their distinctive

By and large, the installation of plastic pipes for water supply may involve three types of materials:

- metal,

- polypropylene,

- polyethylene.

All of them are successfully used for low pressure pipelines, which are used in both residential and industrial sectors. But if polyethylene (PE) is used mainly for the trunk, then polypropylene (PP or PPR) and metal-based laminate are usually used for wiring (there is no abbreviation).

Below we take a closer look at the technical and installation properties of such materials, as well as see the video in this article.

Pipeline

Briefly about polyethylene

- When a water supply system is installed in the private sector, a well or a well (sand or artesian) is usually used as a water intake unit, and a submersible or surface hydrophore pump is used for the pumping station. In any of these options, a polyethylene pipe with a diameter of 32 mm is used as a highway to the junction assembly (with rare exceptions). In this case compression fittings are used for docking for pipes, which can be straight (coupling), angled to 90 ?, tee, quadrangle and reduction for switching to other sections.

- Installation of PE is most often done underground, but it is a rather delicate material, therefore, when it is buried in a trench, some precautions are used, that is, a sand pad.. To do this, pour a layer of sand from 2 cm to 5 cm and put a water pipe on it, after which it is again covered with sand so that solid objects in the soil (stones, metal, glass) do not damage the wall. A considerable advantage of polyethylene is its low price.

Note. In addition to water supply, polyethylene pipes are used for installation of low-pressure sewage systems, as well as cable channels for electrification and communication.

Polypropylene wiring

For typical wiring, polypropylene (ecoplast) is currently used most often, the abbreviation of which in Russian looks like PP, and in Latin - PPR and the dimensions of plastic pipes for water supply from PP vary from 20 mm to 110 mm (outer diameter). In addition, such PPR products can be either single-walled or reinforced (the reinforcing layer is made of either aluminum foil or fiber glass fiber).

The state of PPR depends on the purpose and can again be denoted by the abbreviation PN followed by a number that indicates the density of the wall and the method of using this pipe (for hot or cold water, autonomous or centralized heating).

Thus, PN10 is designed for transporting cold water, with a temperature that does not exceed 20? C in a constant mode, and can quickly reach 45? C. In this case, the wall (depending on the section) can be from 1.9 to 10 mm, and the internal diameter from 16.2 mm to 90 mm and withstand a pressure of 1 MPa (10.2 kg / cm2).

PN20 is designed for both cold and water (such a pipe is often called universal), with a temperature that does not exceed 80? C in a constant mode, and can briefly reach 100? C. In this case, the wall (depending on the cross section) can be from 16 mm to 18.4 mm, and the internal diameter from 10.6 mm to 73.2 mm and withstand a pressure of 2 MPa (20.4 kg / cm2). Usually reinforced with aluminum foil.

PN25 is designed for both cold and water (such a pipe is often called universal), with a temperature that does not exceed 95? C in a constant mode, and can briefly reach 150? C.

In this case, the wall (depending on the cross section) can be from 4.0 mm to 13.3 mm, and the outer diameter from 21.2 mm to 77.9 mm, the inner diameter from 13.2 mm to 50 mm and withstand pressure 2 , 5 MPa (26 kg / cm2). The pipe is usually used for centralized heating, but the reinforcing layer here is not located in the middle of the layer, but closer to the outer edge.

For the PN25 docking, a trimmer is used, as in the photo above, which removes not only the top PPR layer, but also aluminum foil, in order to ensure good adhesion when welding pipes of this type with an electric soldering iron. The diver is selected in accordance with the outer diameter of the polypropylene pipe PN25.

The joining works for polypropylene pipes are carried out with the help of a feedthrough (coupling, angle 32?, 45 ?, 90 ?, tee), reducing and threaded fittings (changing to another material). Fragment number 4 shows the correct fit of the pipe to the fitting, which, with greater depth, causes the edge to flatten out and, as a result, lowers the flow of the water supply.

Note. For polypropylene, repairing plastic pipes of water supply is done very rarely, as the warranty period from the manufacturing plant is from 50 to 100 years. But sometimes a tie-in is required, which, given the stiffness of the pipes, is made using an American fitting.

Metalloplast

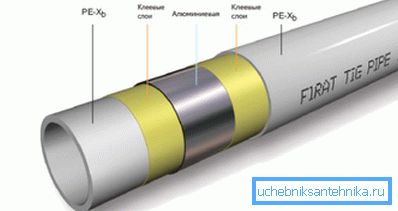

The easiest and fastest material for distributing plumbing is metal-plastic - here soldering work is not required for docking and decoupling - the connection is made with the help of compression metal fittings and sockets. The pipe itself consists of five layers, where the lower and the upper are made of polymers, the middle (reinforcing) of aluminum foil and two binders of glue.

If the working pressure does not exceed 10 atmospheres, and the water temperature is not more than 90? C, then the service life of metal-plastic water supply pipes, according to manufacturers, must be at least 50 years.

The weak point here are the fittings and water sockets for metal-plastic pipes - they are made of metal and, despite the fact that it can be of very high quality, any metal is susceptible to corrosion. In addition, the reinforcing layer is also vulnerable, which can be with or without a joint - in cases where the foil has a seam, this weakens the strength of the reinforcement.

More durable is a seamless reinforcing layer when the foil is dressed in the form of a solid tube or a layer wrapped overlap. Seamless option is also used for laying the floor heating system (instead of polyethylene).

Conclusion

Like any other pipe, metal-plastic can be combined with any materials (metal, polypropylene), but there is one indisputable advantage - the installation of metal-plastic pipes for water supply can be carried out on uneven surfaces - the pipe easily bends. This feature allows you to mount the pipe, laying them, both in a straight line, and with any turns, without using for this metal fittings that are susceptible to corrosion.