Plastic sewer pipes: analysis of the scope, advantages and

Plastic pipes for the sewerage today practically forced out other types of similar materials from the market. Unlike steel, cast iron, asbestos cement and ceramics, plastic is fairly easy to process, which is an invaluable advantage for self-assembly.

Below we describe the main types of polymer pipes, as well as the features of their use in the arrangement of wastewater systems.

Review of materials

As a raw material for the production of tubular products, three types of polymers are commonly used - polyethylene, polypropylene and polyvinyl chloride.

Each material has its own characteristics, and therefore in this section we will look at them in sufficient detail:

- Plastic sewer pipes made of polyvinyl chloride (PVC) occupy one of the most voluminous niches in this market segment. Some have significant strength, easily connected without special devices, withstand intense chemical exposure.

- Polypropylene products are superior to PVC sewer pipes in strength and durability. However, their mechanical characteristics for sewage in most cases are redundant: the drainage system simply does not feel the loads for which polypropylene is designed. In addition, the connection pipe-fitting is usually carried out using special devices for thermoplastic welding, which also complicates installation.

- Polyethylene products can also be used for arranging sewage systems. They are characterized by high chemical resistance, elasticity and an extensive nomenclature. Comparative characteristics of various types of polyethylene pipes are given in the table below.

| Product type | Operational features |

| Corrugated double-layer | Used for outdoor sewage equipment. The shape of the product and the considerable strength of the material reliably protect the internal channel from deformation, even when laying at a considerable (up to 20 m) depth. |

| Pressure head | Differ in the increased durability, are most often used at installation of water supply systems. Also, pressure pipes made of "cross-linked" polyethylene (PEX marking) can be used for trenchless sewage installation. |

| Free-flow | Continuous extrusion polyethylene pipes of low pressure can also be used for the installation of sewer networks. They are somewhat inferior to pressure ones in strength, but in most cases their characteristics are quite enough for long service life. |

Naturally, since there are a variety of types - the characteristics of plastic sewer pipes will also differ. However, for arranging water disposal in a private house or installing pipe wiring in an apartment, almost all the mentioned varieties are suitable, therefore, in most cases, the decisive factor in choosing is affordable price.

Note! If finances allow, it is better to choose products from foreign manufacturers “with the name”, such as OSTENDORF or REHAU. However, products from domestic companies POLITEK, POLITRON, etc. also quite competitive.

Application features

Advantages and disadvantages

The popularity of these products is due to an impressive list of their advantages.

Among those, first of all, the following should be highlighted:

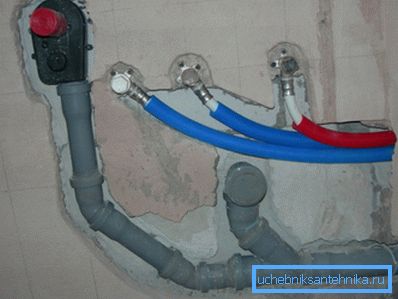

- Easy to handle and install by hand. The plastic from which the pipes are made is easily cut with ordinary tools, and either special glue or welding is used for the joint (for more details, see the next section).

- Light weight. The pipeline has a minimum load on the supporting structures, which is important when equipping water disposal systems in frame buildings. In this case, the strength of the product will be sufficient even for flush mounting under the ground or in the thickness of the floor.

- High resistance to external influences, primarily chemical. For the production of tubular products, maximum inert polymers are used, which are not destroyed or degraded, even after prolonged contact with fecal water.

Note! Unlike metal pipes, plastic pipes do not require the arrangement of cathodic protection, since they do not undergo electrochemical corrosion.

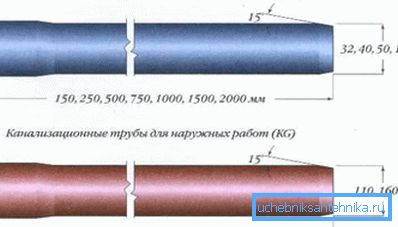

- Extensive range. According to GOST, sewage plastic pipes are produced in diameters from 40 to 110 mm (external ones up to 160 mm), however today there are many non-standard models on the market. In addition, most manufacturers to each pipe diameter produces a full set of fittings for connecting and forming the wiring.

- An important factor is also the price.. Having learned how much a plastic sewer costs (from 120 rubles per linear meter with a diameter of 110 mm), many finally make a choice in favor of this material. For comparison, a similar product made of cast iron will cost you approximately 1,000-1,500 rubles.

Installation Tips

In order for polymeric pipes for sewage to serve as long as possible (up to 50 years), they must be properly installed. Here, the instruction provides for three possible methods of connection, and below we will describe in detail about them.

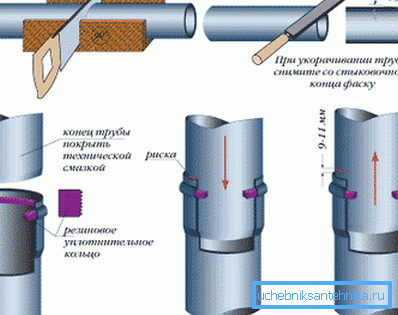

The first method of joining elements is the simplest: we insert the end of one pipe into the socket of another, and the details are fixed due to the elasticity of the inner cuff. This technology is the least time consuming, however, the reliability of the joint leaves much to be desired: when the pipes are deformed or the rubber seals dry out, leakage may occur.

PVC pipelines can be mounted by gluing.

This is done like this:

- We cut off details according to the required size.

- Carefully clean the cutting line, ensuring that there is no burr on the outside and inside.

- Gluing sites are sanded and degreased.

- We apply a special glue on the surface of the socket and on the inner side of the socket.

- We put the parts into each other, making sure that excess glue protrudes at the joint along the entire circumference.

- From above we brush the joint with a brush, evenly distributing the protruded glue and forming an additional protective contour.

For polypropylene most often used weld:

- Cut the pipe we put on the nozzles of a special soldering iron.

- Turn on the machine, warming the material until it softens.

- We connect the pipes without rotation and fix them for 30-40 seconds. During this time, polypropylene will have time to cool down and an airtight weld will be formed at the point of contact.

Note! Such a connection will be permanent, so before starting work it is important to carefully consider the configuration of the sewer pipework, as well as lay in the design sufficient for maintenance the number of inspection hatches.

Conclusion

Plastic pipes for sewage are the best choice if you want to equip the drainage system on your own and with minimal financial costs. At the same time, the quality of pipelines will be quite sufficient in order not to worry about their functioning in the next few decades (see also the article Dimensions of plastic pipes for sewage: GOST and the real range).

The video in this article demonstrates the features of this material in more detail.