Plumbing: installation work

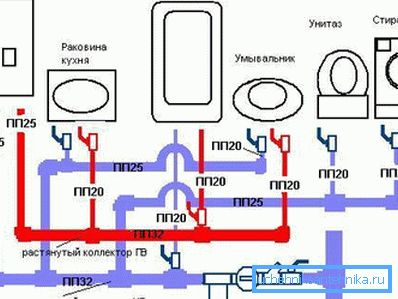

By and large, the basic layout of water distribution in the country, in a country house or in an apartment is absolutely no different, since in any case there is a source of hot and cold water, as well as bathrooms, where pipes are brought. Currently, such wiring in most cases are made of polypropylene.

This is a very reliable material that withstands high temperatures (up to 110? C), and also is easily and quickly welded with a special soldering iron. You will learn how to do this in practice, what pipes are needed for this, and in addition you will be presented with a thematic demonstration of the video in this article.

Assembly work

Materials

- PN-10. The cheapest intra-apartment polypropylene (PPR or PPR) pipe, this PN-10 - instruction allows its use exclusively for cold water with a temperature not exceeding 20? C and as an extreme option - up to 45? C, if the working pressure does not exceed 1 MPa. Usually. Plumbers do not favor such a pipe, preferring a thicker material.

- PN-16. Such a pipe is used much more often, although it does not have reinforcement, since the permissible operating water temperature can be 60? C at a nominal pressure of 1.6 MPa. Such material in some cases can even be used for the supply of hot water, but on the condition that the wiring will be under plaster, which will not allow them to deform.

- PN-20. Plumbing pipes of this type are often called universal, since they can be used both for hot and cold water supply systems and for heating - its working temperature is 95? C at a constant pressure of up to 2 MPa. This is possible due to the reinforcing layer, which may be fiberglass, but more often it is aluminum foil.

- PN-25. But the pipe with such a marking can be used for installation of heating in a private house or in the country with their own hands, where the water temperature has an operating temperature of 95? C and throws of up to 110? C are possible at constant pressure of up to 2.5 MPa. This is possible due to the thickening of the walls and the closer location of the reinforcing layer to the surface, although during installation this creates certain inconveniences (stripping the foil with a shaver).

| vendor code | Wall in mm | Diameter (DN) in mm | Length in m |

| PN-10 for cold water | |||

| PPBB20 PN-10 | 1.9 | 20 | 4/100 |

| PPBB25 PN-10 | 2.3 | 25 | 4/80 |

| PPBB32 PN-10 | 3.0 | 32 | 4/40 |

| PPBB40 PN-10 | 3.7 | 40 | 4/20 |

| PPBB50 PN-10 | 4.6 | 50 | 4/20 |

| PPBB63 PN-10 | 5.8 | 63 | 4/12 |

| PN-20 for cold and hot water | |||

| PPBB20 PN-20 | 3.4 | 20 | 4/100 |

| PPBB25 PN-20 | 4.2 | 25 | 4/80 |

| PPBB32 PN-20 | 5.4 | 32 | 4/40 |

| PPBB40 PN-20 | 6.7 | 40 | 4/20 |

| PPBB50 PN-20 | 8.4 | 50 | 4/20 |

| PPBB63 PN-20 | 10.5 | 63 | 4/12 |

| PN-20 for heating | |||

| Al-PP320 | 3.4 | 20 | 4/100 |

| Al-PP325 | 4.2 | 25 | 4/80 |

| Al-PP332 | 5.4 | 32 | 4/40 |

| Al-PP340 | 6.7 | 40 | 4/20 |

Table of technical parameters PN-10 and PN-20

For docking, turning or moving to another plane of the polypropylene pipe when installing it in the house, in the country or in the apartment with their own hands, special PPR threaded, solder and combined fittings are used. These devices also allow you to make decoupling with pipes of different diameters, for example, when switching from a thicker riser to horizontal wiring.

Note. For welding of polypropylene pipes, three types of electric soldering irons are used - xiphoid, disk and pipe. In technical terms, when installing a water supply system, there is no difference between them, but in the first two types, pair nozzles are used, and for the latter, unpaired ones. All nozzles are made of their aluminum alloy, but the higher quality ones have a Teflon coating that protects molten polypropylene from sticking.

Welding work

Let's start with the fact that the layout of water pipes in an apartment, in a bathhouse or in the country begins with a markup, that is, you will need to determine exactly where and how high a particular bathroom will be and mark them with chalk or technical pencil . This will allow you to accurately calculate the required PPR metric, as well as the type and approximate number of threaded, soldering and combined (reduction) fittings needed for docking and bends.

We say the approximate number, since only threaded fittings can be accurately calculated for output to different plumbing fixtures, but the number of fittings (tees, angles, couplings, bypass and plug) can always fluctuate. Therefore, they are bought with a small margin.

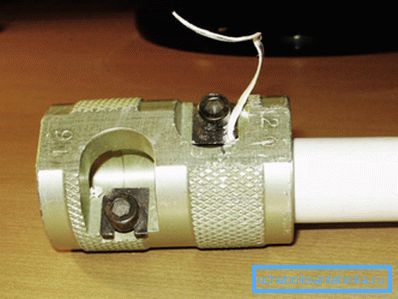

Depending on which line you are driving (hot or cold), the marking of the polypropylene pipe may also change. For example, you can lay the supply of hot water from an electric boiler or gas column with a PN-25 pipe, but in this case, before the welding work, its end should be processed with a shaver.

This device is somewhat reminiscent of a school pencil sharpener, only in this case you are not shooting a tree, but an SPR layer and aluminum foil, exposing the inner SPR layer for soldering.

To weld polypropylene in an apartment or in a private house with your hands at room temperature, you need to heat the soldering iron to 280-290? C, and if it is cold, set the thermostat to full capacity - usually it is 300? C.

A fitting is put on the hot nozzle from the thin side (it is put on it), and a pipe is inserted into the thicker part — a retention time of 5–6 seconds so that the flow tube warms up well and provides sufficient adhesion. After that, both elements must be removed simultaneously and connected with the same holding time.

| Diameter in mm | Solder depth in mm | Heating time in seconds. | Cooling time in min. |

| 20 | 14–17 | 6 | 2 |

| 25 | 15–19 | 7 | 2 |

| 32 | 16–22 | eight | four |

| 40 | 18-24 | 12 | four |

| 50 | 20–27 | 18 | four |

| 63 | 24–30 | 24 | 6 |

| 75 | 26–32 | thirty | 6 |

| 90 | 29–35 | 40 | eight |

Table of welding parameters of SPR pipes

During welding work it is very important to adhere to the soldering depth - this is the distance that the pipe will go into the fitting. Pay attention to the table, which is located a little higher and, according to the diameter, you can put a mark on the end of the mark with a pencil or marker - with time you will not need marks - experience allows you to stick to the desired distance automatically.

The fact is that if the pipe penetrates into the fitting deeper than the specified distance, it partially or even completely blocks the passage, which means that this node will have to be cut and in its place with the help of pipe couplings to solder a new one.

You can weld all the nodes separately in the house or in the apartment with polypropylene, that is, you can solder each joint directly at the place of its operation, but this is very inconvenient, since the wall itself will interfere with you, as well as different turns, protrusions, the impossibility of bending the pipe and etc.

Therefore, it is best to weld the nodes in whole blocks separately, as shown in the upper photo, and then connect them at the place of use (floor, wall, ceiling). Do not forget that each section of the pipe must be carefully measured, and each fitting must be welded at the angle at which it will be operated.

Note. Polypropylene can be installed on top of the wall to be fixed with plastic or metal brackets. But it is best to do hidden installation, under plaster or frame lining, because PPR is not susceptible to corrosion and will serve for many years.

Conclusion

If you have the necessary tools - a tape measure, scissors and a soldering iron, then you can always do the wiring of plumbing or heating in your own house or apartment with your own hands. But at the same time it is very desirable to have a partner who can hold the welded block in the right position at the right moment.