Plumbing insulation - the main options for the protection of

If in urban apartments this issue is irrelevant, then when living in the private sector, as well as in suburban and suburban areas, it is quite acute. Most often, in the city of communications, they are built by specialized organizations, which initially do everything in accordance with technology. But if you want to warm the water supply system in the country - you can do all the necessary work with your own hands, the main thing is to know the basic requirements of the technology and to strictly follow the recommendations.

The most important nuances in the work

Consider what factors should pay close attention to the installation process:

| Features of the region | Before insulating the well and the water supply system for the winter, it should be clarified in the respective organizations what the maximum depth of frost penetration is. The choice of a specific option and the total amount of work depends on it. Naturally, the shallower the depth of the gasket, the more thoroughly the insulation required. |

| Applicable Materials | Whichever thermal insulation option you choose, all the materials and products used must meet quality standards, because this is the only way to guarantee reliable communication protection. |

| Problem areas | As you know, the most dangerous in terms of freezing are the turns of the pipeline, stop valves, as well as entry points into the house. They should be given the closest attention and warming especially carefully. |

Tip! You can equip problem areas with additional heating, which will be included only in the coldest periods. This will eliminate problems when large frosts occur and save money, because energy will be consumed only when necessary.

The main options for thermal insulation

If you are thinking about how to insulate the water supply system in the country with your own hands, then you should begin by defining the material with which the work will be carried out. There are various offers on the market, and each of them has its own characteristics.

Types of materials

To date, the most popular and sought after options are the following:

- Insulation of foam plastic is distinguished by a low price and a very small mass, so that you can easily carry out the work with your own hands without attracting helpers.. This material has a fairly high thermal insulation properties, while it is easy to lay. In addition, the service life of such structures is several decades, but this is under the condition that they are not deformed.

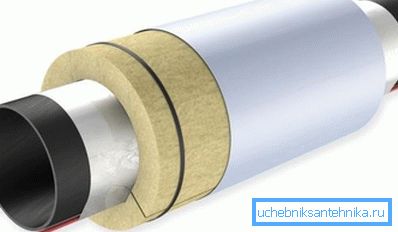

- Warming of the water pipe in the street is recommended to do with the help of polyurethane foam segments. They are similar to the above option, but unlike it have much higher strength and can withstand even significant loads. They also implemented a mortise connection, and fixing of each element is done with plastic clamps.

- Products made of basalt wool have high levels of thermal insulation, but need additional protection from moisture, for this purpose any waterproofing materials are used - from traditional roofing material to more modern products.. This option is most often used on large diameter pipelines.

- Another option - the elements of mineral wool, with high performance properties of this material is quite soft, in addition, it must be protected from moisture. The best use is for risers, entrances to the house and communications under the foundation, that is, all the places where flexibility is required and the loads are low.

- Consider how to insulate the plumbing underground without the use of traditional options.. To do this, you will need a special heating cable for heating the pipes, and it can be laid both outside the pipes and inside them (in this case, heating is most effective, since energy is spent solely on heating the working environment). Connecting this option will not cause difficulties even for people without relevant experience.

Workflow organization

Installation depends on the option that you chose as the primary.

When using pipe insulation work is performed as follows:

- The pipeline is laid, if it is not located in the tray, the soil around it is cleared to ensure convenient access.

- Insulating elements are installed carefully to prevent damage. Each section is fixed with plastic clamps or with the use of special high-strength adhesive tape. After fixing, the elements should stand tightly and securely.

Note! To improve the insulating properties and further strengthen the system, the elements are set offset by 15 cm relative to each other. This allows you to mount insulation with overlap, eliminating the cooling of individual sections through the seam connections.

- It is desirable to strengthen all connections also with the help of scotch tape. If additional protective material will be installed from the outside, this is done after the fastening of the main elements is completed.

- Turns and bends are closed with the help of special shaped parts. They greatly simplify the work and provide adequate reliability in difficult areas.

Using a heating cable, remember the following recommendations:

- It is very important to conduct a competent calculation to determine the required power.

- Installation and connection instructions are required to study before starting work.

- Laying should be carried out according to the planned parameters.

- The design should not have connections in length.

Conclusion

Competent insulation of water supply in the ground and the place of entry into the house ensures its performance in all weather conditions. The video in this article will help to understand some of the nuances of the topic in more detail and in detail.