Polypropylene pipes for heating: 5 stages of installation of

Beginners who do not have enough practical experience, when deciding on the choice of certain technologies for designing a climate control system, are wondering whether polypropylene pipes can be used for heating. An unambiguous answer you can get only by reading the material posted below.

Polymer Features

First of all, it should be noted that this type of plastic, like any other, is excellent for transporting a liquid medium, which is the coolant in the room heating system.

In addition, the heating of polypropylene pipes has many advantages that favorably distinguish this solution against the background of existing alternatives.

These include:

- Easy installation procedure. Pipes made of polypropylene for heating are joined together by soldering. This technology, unlike the welding of steel parts, does not cause difficulties even for a novice master and does not require the involvement of specialists from the side, the price of which services are quite high.

- Polypropylene, being one of the types of plastic, does not oxidize in air, because the heating system of polypropylene pipes is absolutely not subject to corrosion. This greatly prolongs its life.

- On the inner surface of the pipelines, due to the exceptional smoothness of the plastic, there is no deposition of mineral salts dissolved in water.. Therefore, even after many years, the capacity of the heating system and, accordingly, its efficiency will not decrease.

- Polypropylene pipe for heating, despite the flexibility, has high mechanical strength. This means that the indoor air heating network constructed from this kind of polymer can withstand the high temperature of the heat transfer medium and the increased pressure of the circulating fluid.

- Properly designed and designed heating scheme made of polypropylene pipes, due to the high rate of flow of fluid, differs in the increased efficiency in comparison with the heating made of metal details.

- Low estimated cost of installation of the heating system makes it possible to save.

Tip! Considering that pipes for heating made of polypropylene are easy to weld with each other with your own hands, you can easily design the necessary water supply network on your own, further reducing your costs.

Selection of materials

There are various types of polypropylene pipes. But not every variety of them is suitable for water supply and heating. All necessary technical characteristics are reflected in GOST R 52134-2003.

This document also indicates the diameter of polypropylene pipes for heating - the table in it allows you to choose the right type of parts depending on temperature, pressure and type of heat carrier.

The marking of polypropylene pipes will help to distinguish between different polymer parts: PN 20 and PN 25 grades are suitable for heating. Plastic used in their manufacture makes it possible to transport liquid whose temperature is 90 degrees Celsius (the standard also provides for a short-term excess of this parameter by 10 degrees) .

The numbers after the letter marking indicate that the coolant pressure in the heating system may be 20 or 25 times higher than atmospheric.

It is better to use polypropylene pipes and fittings for heating, labeled PN 25. These products are reinforced with a thin metal foil, which gives the water transport network additional reliability.

Regardless of whether you are installing a new network of space heating or a banal replacement of pipes, before purchasing them you should make sure of the quality of:

- the product must have a perfectly round and even shape;

- the structure of the plastic from which the pipes are cast must be uniform throughout their length;

- on the pipe must necessarily be marking, through which you can find out the date of its manufacture, batch number and other technical parameters.

Note! For the manufacture of a heating network, you need to buy pipes and fittings connecting them produced by one plant. Each manufacturer may make small changes in the composition of the polymer used. Subsequently, when soldering, this may lead to the appearance of a marriage and a loose connection of parts with each other. In addition, the sizes of products from different manufacturers may slightly differ.

Assembly of the heating system

Stage 1. Calculations

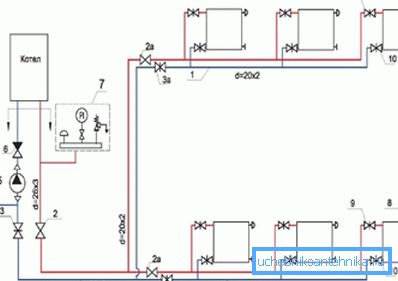

Despite the fact that the installation of the heating system can be done independently, it is advisable to design it to a professional engineer. Only he can calculate all the necessary parameters and draw up a drawing according to which the assembly will be carried out.

The choice of a specific type of heating is based on the characteristics of the room and its area. In addition, depending on the used radiators, systems with upper coolant supply and lower ones can be installed.

Before drawing up the documentation, the specialist must inspect the dwelling, remove its actual dimensions, verify the presence or absence of insulation, and so on.

The final project, in addition to directly drawing, should indicate:

- What is the diameter of polypropylene pipes to be used when designing a heating system for the premises;

- angles at which the main pipelines must be laid to ensure the natural flow of water;

- fixing points and ways to connect radiators and other appliances (boiler, water heater, etc.).

Stage 2. Required Tools

Heating with polypropylene pipes will function for a long time and efficiently only if during the installation the soldering procedure was carefully followed.

In this work, you will need not only directly pipes and fittings, but also special equipment:

- special welding machine for soldering polypropylene (it is also called "iron" or "soldering iron");

- nozzles that allow to heat parts of different diameters;

- special pipe cutter or scissors, with which you can cut pieces of pipe of the desired length;

- shaver - a device for removing from the end of the pipe the remnants of the reinforcing foil, which can interfere with the soldering;

- Faskosnimitel - a device that makes a bevel on the cut of the pipe, thanks to which it enters the fitting for connecting pipes better.

Stage 3. Preparation

Before proceeding to the connection, it is necessary in a special way to prepare the pipes for use:

- With the help of special scissors or pipe cutter, the acquired polypropylene pipes are cut into lengths you need;

- From the end of the pipe (its outer part) a chamfer is removed with a width of 3 mm at an angle of 15 degrees. Thanks to this operation, the pipe is easier to enter the connecting fittings. In addition, the sharp end does not “clean off” the layer of heated plastic, which can lead to a violation of the tightness of the joint in the future.

- The pipe and the inner surface of the fitting should be thoroughly cleaned from dust and debris, then degreased with a special compound.

Stage 4. Welding

It is necessary to begin work with preparation of the equipment:

- Install the iron on a special stand, which facilitates its use and protects against injury.

- The thermostat of the device should be set at 270 degrees Celsius. This temperature is optimal for the welding of polypropylene pipes during installation of the heating system.

- After that, you need to wait for the device to heat up. The end of this process will be indicated by a green LED.

The process of connecting pipes to each other is performed in the following sequence:

- A fitting is placed on the soldering iron pin, and a pipe is inserted into the socket. This must be done simultaneously so that the heating and melting of the plastic on both parts takes place evenly.

- The warm-up time depends on the diameter of the parts used and is indicated in the accompanying documentation for the soldering iron.

- At the end of melting, you need to remove the pipe and fitting from the soldering iron and insert them into each other.

To ensure maximum quality during the docking, it is advisable to follow these tips:

- connecting parts, you need to make sure that their axial line is strictly parallel;

- during the hardening of plastic can not move the pipe and fitting;

- when joining products it is forbidden to turn them around its axis.

Stage 5. Fixing

Connection with radiators of heating is made using special quick-detachable elements, which are attached to the end sections of the heating pipelines.

In order to avoid warping during operation, all finished parts should be fixed on the wall with clamps or brackets. They must be designed to withstand the weight of the pipe filled with water. In the same way mounted radiators.

Conclusion

The instructions provided in this article describe in detail the sequence of actions that allows you to equip polypropylene single-pipe heating of a private house with your own hands. Similar construction is carried out and the construction of a similar scheme in the apartment. More details about our topic will tell the video offered to your attention.