Polypropylene pipes: what you need to know

At the moment, polypropylene pipes according to GOST R 52134-2003 are confidently pushing metal counterparts from all applications. The reasons for this situation are simple - products are available, reliable, easy to install, have a long service life, do not rust and do not overgrow with deposits.

What you need to consider in the first place

For the production of polypropylene products used raw materials 3 modifications.

Varieties of polymeric material

- Homo-polymer is type I. It is labeled as PP-H in the international classification and PP-G in the Russian.

- The block copolymer, which is type II, is designated PP-B / PP-B.

- A random copolymer of type III is classified as PP-R / PP-R.

Note! State standard says that in the manufacture of water and heating pipes, you can use the material of all three varieties. However, manufacturers now prefer to use PP-R. This plastic is the most versatile. Its main advantage is resistance to extreme temperatures.

- About how to make a random copolymer. It is obtained by changing the structure of polypropylene when ethylene is introduced into its molecular chains. This "neighborhood" improves the characteristics of the material: its viscosity, elasticity, resistance to high temperatures

- By varying the proportions of PP and ethylene, it is possible to obtain various subspecies of a random copolymer. Recently, PP-R / C has become very popular.

- More recently, another subtype of this material has been developed - PP-R / CT. Its crystal lattice has improved 40/50% performance.

The manufacture of polypropylene pipes in this case takes place using a special cooling method. In its course creates a structure consisting of the smallest crystals.

It turns out very dense and flexible at the same time. From such raw materials it is possible to make products that, with a long service life, have resistance to high pressure (up to 18/20 bar) and positive temperatures up to + 95/110 °.

Advantages and disadvantages of pipelines from PP

- The price of products is less, and they themselves are lighter than their metal counterparts.

- Installing them yourself is much easier. Diffusion welding makes it possible to assemble a completely sealed network in the shortest possible time.

- The elasticity of the material makes it possible to use flexible polypropylene products in floor heating systems.

- Polypropylene products are chemically inert. That is - it is non-toxic and does not affect the quality of the coolant / water.

- The polymer does not rust, sediments do not build up on its particularly smooth inner surface.

- The service life of polypropylene pipes is very long and depends on the scope of their application. Analogs for cold water supply have been used for up to 50 years, and pipe products for hot water and heating for up to 25 years.

- They are able to withstand changes in temperature and pressure in the network in a very wide range.

- Polypropylene has good sound insulation. Therefore, pipelines from it do not make noise when water, drains or coolant flows through them.

Lacks of polypropylene pipes are insignificant. The main one is the high fluidity of unreinforced material. Therefore, the elements of the system should be securely fixed to any basis.

Product Specifications

Selectable products from the PP must exactly match the characteristics of the created engineering communication. Each polypropylene pipe according to GOST 52134-2003 belongs to a class. They are listed in the table below.

| Class | Scope of application |

| I | Hot water up to + 60 ° |

| II | Hot water up to + 70 ° |

| III | Low-temperature floor heating to + 45 ° |

| IV | High-temperature floor and low-temperature radiator heating up to + 70 ° |

| V | High temperature radiator heating up to + 95 ° |

| Hv | Cold water |

Product Varieties

Any pipeline has its own distinctive features. It is extremely important in this case the temperature of the internal environment in the system and the working pressure in it.

The table below shows a range of polypropylene pipes, according to their temperature characteristics and ability to withstand pressure.

| Mark | Purpose and specifications |

| PN-10 | Cold water supply up to + 20 °, warm floors up to 45 °, pressure 1 MPa |

| PN-16 | Hot (up to + 60 °) and cold water supply, pressure 1.6 MPa |

| PN-20 | Hot water up to + 95 °, pressure 2 MPa |

| PN-25 | Reinforced for hot water and heating up to + 95 °, pressure 2.5 MPa |

Composite analogues

Not only solid but also combined pipes are made from polypropylene.

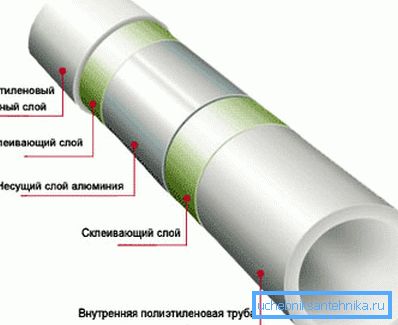

- They can be reinforced with fiberglass or aluminum foil..

- Solid analogues can only be used for hot and cold water.. The reliability of polypropylene pipes, reinforced with metal or fiberglass, is such that they are suitable for all engineering systems.

- The main advantage of such products is low thermal elongation.. For products with fiberglass it is 2 times less, for aluminum-plastic counterparts - by 4 times than for solid PP pipes.

- The metal layer in the pipes can be solid or perforated..

Note! The instruction highlights the second option. With such reinforcement, diffusion penetration of oxygen into the working environment of the system is excluded. This increases the efficiency of closed heating networks with their great length.

To install the PP pipe was correct, it should be carried out according to the SNiP.

Here is the documentation that relates to this process:

- SP №40 / 101 "Random copolymer";

- SNIP № 2.04.05 / 91 "Ventilation, heating and air conditioning";

- СНиП №2.04.01 / 85 "Internal sewage and water mains of buildings".

The most common products on the Russian market

The table below shows the rating of polypropylene pipes, which are most popular in the Russian construction market.

| A place | A country | Brands |

| one | Germany | Banninger, Aquatherm, Wefatherm, Rehau |

| 2 | Czech | Ecoplastics, FV-Plast |

| 3 | Turkey | Tebo, Pilsa, Jakko, Vesbo, Firat, Kalde, Valtek |

| four | China | Dyzain, Blue Ocean |

| five | Russia | RVK, Politek, Heisskraft, Santrade, Pro Aqua |

Conclusion

GOST for polypropylene pipes defines them as durable, reliable and durable material. Such products can be used in hot and cold water supply, heating, ventilation and sewage systems. Watch the video in this article, it will let you know a lot more.