Polypropylene reinforced pipe: the main types and technology

Today, polypropylene (PP) flexible reinforced pipe, which recently appeared on the domestic market, is becoming an excellent alternative to traditional metal pipelines. These types of materials are distinguished by increased strength characteristics, resistance to temperature fluctuations and the ability to withstand aggressive environmental influences.

Types of reinforced materials

Propylene pipes on the market are presented in a wide range. The lowest price for single-layer species. Multilayer pipes consisting of three or more layers are considered as a material of increased strength (read also the article Polypropylene reinforced pipes and their features).

Additional layers increase strength and other technical characteristics.

The reinforcing layer can be made of various materials:

- Aluminum allows you to increase the strength of the final product;

- Fiberglass reinforcement is applied to the inner surface, making it even stronger;

- In addition, layers of hot melt are present in multilayer pipes, which also increase strength.

Marking

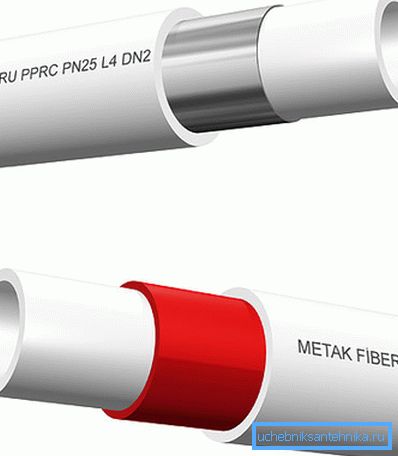

A fiberglass reinforced pipe may be different from other pipes due to the markings on its surface. The fact is that the upper and lower layers of such products are absolutely identical, and in the middle there is a reinforcing layer.

Depending on how this middle layer is, the following symbols are applied:

- PPR-FB-PPR - designation of the presence of fiberglass reinforcement;

- PPR-AL-PPR (PPR-AL-PEX) - indicates the presence of aluminum reinforcement.

In fact, it turns out that the technical characteristics of the pipe reinforced with glass fiber and reinforced with aluminum are almost identical.

Note! In the market, you can meet with fiberglass of different colors, but the hue of such material does not affect its characteristics, and therefore should not affect your choice.

Why make hardening

There are several reasons why products are reinforced:

- Tightening the frame. Polypropylene - the material is quite flexible and ductile. The hardening process will avoid the change in pipe size in length and width;

- The ability to maintain all dimensions and shape, even in conditions of high temperature;

- The ability to maintain wall thickness even under high pressure and temperature conditions.

Advantages of reinforced polypropylene materials

A pipeline of this kind of material has a number of advantages:

- Increased wear resistance;

- Ease and simplicity of installation;

- Long operational period;

- Universality of use;

- High level of resistance to external aggressive influences, temperature changes and chemical reagents;

- Impossibility of blockages and rust.

Unlike older products with threaded connections, glass fiber reinforced pipes do not need special maintenance. The pipeline, created with their help, fits perfectly into the interior of any type.

Note! Such pipes are great for laying walls and walls in the thickness, which allows you to save the useful floor space and does not spoil the appearance of the created decoration.

Such a pipeline has an unlimited service life, and at the same time it will not require regular repair or restoration work.

PP materials to create a heating system

Durability and reliability allow the use of reinforced pipes for heating, which are more comfortable during the operation of the system.

Installation of pipeline systems using reinforced polypropylene materials does not take much of your time and money. This type of products are connected by soldering, as well as PVC-reinforced pipe.

During operation, such reinforced pipes will not stratify and will not lose the integrity of their structure.

Council Having decided to undertake the installation of a pipeline of polypropylene fiberglass-reinforced pipes with their own hands, it is necessary to take into account such a parameter as linear expansion. In such pipes it is 6% higher than in metal.

Installation Features

Instructions for welding pipes with a diameter of 10, 16 and 20 is no different. This procedure is implemented using a specialized tool.

Work is done as follows:

- Before the start of installation work, it is necessary to prepare for this process, making a clear plan of action and drawing a line with reference to the rooms in the house;

- The pipe is cut into pieces of the required length;

Council If we are talking about pipes reinforced with aluminum, then it will be necessary to remove the reinforcement at a distance of a few millimeters from the edge. This can be done with a tool such as a flat-tool for a reinforced pipe.

- With the help of a specialized tool, the edge of the pipe and connecting fittings are heated to the desired temperature;

- The heated elements are connected and fixed in one position until they are fully glued.

In the process of gluing the pipe and fitting can not rotate these parts. Otherwise, you risk a leaky connection.

It is also necessary to pay attention to the pipes in the process of heating and connection, eliminating the possibility of nodules, which can cause obstructions and constipation of the system.

If the system is being laid not in the wall, but on its surface, then for fasteners, clamps should be used that are attached to the wall, and then a pipe is passed through them.

Finally

Reinforced propylene pipes proved to be in practice, as products are much more efficient than metallic materials. In the near future, they will completely replace almost all metal pipelines (see also the article Polymer pipes: how to choose the appropriate material for the arrangement of engineering networks).

Installation of such products is quite simple, and you can easily cope with this task yourself without the involvement of specialists from the outside. And read the visual instructions on how to do it correctly, you can by viewing the video in this article.