Polypropylene reinforced pipes and their features

Polypropylene reinforced pipes for heating and plumbing are a completely new material that has been on the market for just a few years. Therefore, many are interested in - what is the advantage of these pipes and is it important reinforcement? Next, we will try to answer this question and consider all the features of polypropylene pipes.

Polypropylene Disadvantages

Polypropylene pipes have become one of the most popular types of plastic pipes, as they have a number of positive qualities (find out here how and for what purpose the drainage pipes are used at the site).

However, they are not without flaws that are associated with the characteristics of the material itself:

- Polypropylene is a low-melting plastic;

- It has a high coefficient of thermal expansion.

Now let's take a closer look at the shortcomings of pipelines made of this material.

Heat resistance

The stated melting point of the material is 175 degrees Celsius, however, it begins to soften at a much lower temperature - 140 degrees. The guaranteed temperature at which the products meet all the declared characteristics and the pipeline works as expected is 95 degrees Celsius (for some varieties it is even lower).

Such a large temperature “margin” is due to the fact that, simultaneously with the impact on the walls of a polypropylene pipeline, at the same time, high temperature and pressure, its durability is much less than when exposed to these factors separately.

Temperature expansion

As you know, when heated, all materials expand, only some are larger, while others are smaller. Polypropylene refers to those that expands very strongly. Of course, this property does not matter for a cold water main, but when arranging heating systems or a hot water main, it causes a lot of problems:

| Aesthetics | When lengthening, the pipeline goes unattractive waves |

| Integrity of decorative coatings | In the case of hidden installation of the pipeline, for example, in the coating of walls or under the screed, the expansion leads to cracking of the coating. |

Problem solving

As you probably guessed, the solution to all of the above problems are reinforced polypropylene pipes. The fact is that the reinforcement serves as a solid frame for the pipe, which does not allow it to increase when heated in length and width.

In addition, with excessive heat, the reinforcement does not allow the pipe to swell and burst. True, the maximum operating temperature declared by the manufacturers is still 95 degrees Celsius, but the reinforced pipes are still much more heat resistant.

Types of reinforcement

Today, there are two types of reinforcement:

- Aluminum;

- Fiberglass.

Each type of reinforcement gives the product certain properties.

Aluminum

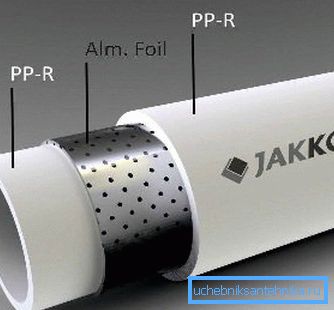

Aluminum reinforced polypropylene pipes consist of several layers, between which aluminum foil is placed. The layers are glued together with polypropylene glue.

Note! The quality of multilayer products depends largely on the quality of adhesive bonding. Therefore, it is not uncommon for cheap pipes under certain operating conditions to stratify.

I must say that aluminum reinforcement is of two types:

- Solid;

- Armored.

Fiberglass

Fiberglass is an alternative to aluminum. As in the previous case, layers of polypropylene are located outside and inside the product, and a layer of fiberglass is located inside. Moreover, all layers are monolithic.

The inner layer of these products is welded with the outer and inner. As a result, polypropylene fastens fiberglass fibers, and fiberglass in turn prevents it from deforming. Unlike the previous type of reinforcement, when using fiberglass, glue is not used.

The disadvantage of fiberglass is that it increases the weight of the product, but for the price of its price is slightly reduced. True, the cost depends on the manufacturer.

In addition, it should be noted that the glass-fiber-reinforced heating pipe saturates the coolant with oxygen, as a result of which the boilers rust. However, according to many experts, this problem is more far-fetched than real, since there are no concrete numbers.

Installation Features

The soldering of reinforced polypropylene pipes is performed according to the same principle as conventional polypropylene products:

- First of all, the products are cut to size, in accordance with the scheme of the future pipeline;

- Then the fittings and pipes are heated with a special soldering iron until softened;

- Heated elements are combined and held in this position until the materials harden, resulting in a reliable connection.

However, there is a difference - the installation manual for pipes reinforced with aluminum contains another technological process. Before heating the product with a soldering iron, it must be cleaned, i.e. remove the aluminum layer.

However, nothing complicated about it.

If the aluminum layer is located outside, the operation is performed as follows:

- The pipe must be inserted into a special simple sleeve with knives

- Next, you need to rotate the tool with your own hands several times.

- After this, the spike is performed according to the standard scheme.

Note! Polypropylene pipes for heating aluminum-reinforced should contain a solid foil. Perforated reinforcement can be used for plumbing hot water.

For pipes with reinforcement located inside, a slightly more complicated tool is used - end facer. The principle of its operation is that it selects the inner layer from the end of the pipe, which ensures a reliable joint of the pipeline elements.

This operation prevents:

- Pipeline delamination;

- The destruction of aluminum as a result of electrochemical processes that occur when there is a potential difference in metals.

As for the soldering of products reinforced with fiberglass, the process is no different from the soldering of single-layer polypropylene.

Tip! It is possible to distinguish polypropylene pipes reinforced with fiberglass along the junction - they have three layers of approximately the same thickness.

That's all the features that you need to read before soldering reinforced polypropylene pipes.

Conclusion

The reinforcement of polypropylene pipes allows to improve their basic characteristics. Therefore, they very quickly began to be in demand. Most often they are used for the device heating systems and pipelines, in fact, for these purposes they were developed.

From the video in this article, you can get more information on this topic.