Polypropylene tubes - a detailed overview of the perspective

The polypropylene pipeline confidently wins the heart of man. Every year more and more people install the PP pipes in the apartments instead of the usual steel or metal-plastic. The reasons for this popularity lie in the exceptional performance and low price of polypropylene.

Advantages and disadvantages of PP pipeline

Replacing pipes with polypropylene looks justified, because compared with other materials (for example, steel, copper, etc.), polypropylene stands out favorably:

- low weight;

- ease of installation, soldering is done in minutes using a special soldering iron. Connection in the end - one-piece;

- smooth inner surface, thanks to this, the material wears less;

- low cost;

- elasticity.

As for the shortcomings, it is possible to distinguish unless:

- high linear expansion ratio. Partly, this disadvantage is solved with the help of plastic reinforcement with aluminum foil or fiberglass, the reinforcing layer is placed between the layers of polypropylene and acts as an expansion limit when heated.

- the temperature of the coolant should not exceed 95? Some types of pipes can withstand up to 110? С, but only for a short time, if the temperature of the heat carrier will always be so, then the appearance of waves is inevitable.

For example, a pipe made of polypropylene PN 20 to 20 marked PPR-AL-PEX (PPR-AL-PPR) can be successfully used not only for cold but also for hot water supply and even for the installation of a heating system. Such marking indicates that the reinforcement was carried out with aluminum foil.

Note! In order for pipes not to go in waves on a long straight section, it is recommended to use U-shaped expansion joints. Thanks to them, there will be no bending when heating, only the ends of the compensator will slightly converge.

Polypropylene under the microscope

The technical characteristics of polypropylene pipes are largely determined by the properties of the plastic itself.

There are several types of polymers:

- homopolymer (characterized by brittleness at low temperature);

- block copolymer - characterized by high elasticity, but wears out quickly.

But especially valuable is a random copolymer (it is also called a polymer of the 3rd type). At low temperature, it does not crumble, and the upper limit of the working temperature is at 90–95 ?.

Such outstanding properties are achieved due to the introduction of ethylene into the molecular chain of PP. It is this “neighbor” that gives plastic such unusual properties. It is important that the price of the material practically does not change in a big way.

It can be noted that the type 3 PP is completely environmentally friendly, which is especially important when processing it. It is produced in the form of colorless granules.

Regulatory requirements

In this regard, there is a big gap in the Russian regulatory framework. It can be noted except that the document of 2003 - GOST R 52134-2003, it formulated the main requirements for pipelines of thermoplastics operating in the pressure mode.

The document contains a range with an indication of all sizes of PP pipes, it also normalizes the maximum deviations of the geometric dimensions. In addition, attention is paid to the calculated part - formulas are given for calculating the strength of the pipeline walls and its durability.

You can also see the marking of pipes of thermoplastics. For example, the PVC-U designation according to GOST means that unplasticized polyvinyl chloride was used for production, and the letters PB indicate that the pipeline material is polybutene.

In addition to the pipeline itself, attention in the standard is also paid to fittings (requirements relate to the tightness of the joints). The document also describes the process of testing the pipe and the joint for strength and tightness.

Pipeline selection

When the work on the replacement of plumbing or heating in the house is done by hand, the question of choosing the right pipe is quite relevant. Thus it is necessary to proceed from the operating conditions of the system.

Cold water supply

The standard pressure in the cold water supply system should be between 0.3 and 6.0 atm, so PN10 pipes can be used to supply water (the number 10 indicates the maximum pressure that the pipeline can withstand without deformation).

For the layout of the apartment is quite suitable pipe made of polypropylene 25 mm. Of course, no one will prohibit the use of reinforced piping for cold water, but this will simply lead to unnecessary costs, and will not affect the durability of the system.

Hot water supply

In the system of supplying consumers with hot water, the maximum pressure value is somewhat less; it should not exceed 4.5 MPa. As for the selection of the pipeline, here we must also take into account the effect of temperature.

Note! The pressure that the pipe can withstand is indicated for room temperature (20? С), when heated to 80 - 90? С this value decreases by about 3 times.

As in the case of cold water supply, the diameter of the pipes that dissipate hot water in the apartment does not usually exceed 25-32 mm. But for risers it can be used a pipe made of polypropylene 50 mm. Selection can be performed according to the table.

For hot water is most often used pipeline with marking PN20. You can also meet a less common pipe - PN16, but for it the maximum coolant temperature is limited to 60? С.

Heating system

The temperature of the coolant can reach 95? С, which, in combination with the pressure in the system, places increased demands on the pipeline. The installation instructions for heating systems allow using only reinforced PP pipes (PN20 or PN25). A pipe made of polypropylene PN 25 to 20c with PPR-FB-PPR marking indicates that reinforcement was performed using fiberglass - this is the main difference between PN25 and PN20.

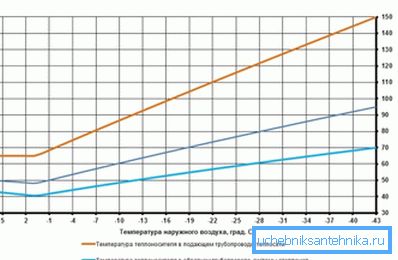

In the case of autonomous heating in the area immediately adjacent to the boiler, the temperature of the coolant may exceed 100? С, so the PP will not work here. To solve this problem, a small section of the steel pipe usually goes from the boiler, and the rest of the wiring is done using polypropylene. The average outdoor temperature also affects the temperature of the heat carrier.

As for the diameters, then the following sizes are most often used:

- for wiring on floors - no more than 32 mm;

- for the risers of the heating system, a polypropylene pipe of 63 mm may well be used.

Corrugated PP Pipeline

Corrugated pipes can be used for sewer systems or as cable channels (of course, such pipes are produced of much smaller diameter). Sewerage works in free-flow mode, and the cable channel does not undergo serious loads at all, therefore the requirements for such a pipeline are not so high.

The corrugated pipe from polypropylene for sewerage is issued two-layer. Outside, the surface is wavy, which increases the rigidity and allows you to more effectively transfer the pressure of the soil, and inside - smooth, which practically does not interfere in the path of the water flow.

As for the cable channels, such tubes are produced in single layers, for them polypropylene of increased elasticity is used. In this case, the main characteristic is considered to be fire safety, the PCB should not burn and release harmful substances into the atmosphere.

In conclusion

Polypropylene pipes are deservedly considered almost the best choice for the organization of plumbing and heating systems. Cheapness, high durability and ease of installation allow them to gradually oust competitors from the market in the face of steel or copper pipelines.

The information presented in the article will help you navigate when choosing a pipe for a specific task. The video in this article details the main types of PP pipes.