Popular ways to connect pipes - a detailed overview

When installing a heating system, sewage system and water supply, it is imperative to have to solve the problem of connecting pipes. At the same time, it is necessary to take into account the material from which the pipeline is made, the operating conditions of the system, and many other parameters. Studying a variety of existing methods of connection, it is worthwhile to consider the most popular options.

Pipe Connection Classification

For convenience, all types of pipeline connections are divided into 2 large groups:

- separable - it is possible to disassemble the joint with your own hands without violating the integrity of the material. A threaded connection can be considered a classic example in this group, a thread is cut at the ends of pipeline sections and, if necessary, the junction can be easily disassembled;

- one-piece - disassembly is possible, but the pipeline material will suffer. A welded joint can serve as an example in this case. Welding of metal will not allow to disassemble the pipeline in the future, it can only be cut into pieces.

The proposed classification is too general. And if in the case of a permanent joint there are not so many options (welding, gluing or socketing), then in the category of detachable joints there are several interesting ways.

Popular types of pipeline connections

In addition to practicality, the choice of the type of dock also needs to take into account the material properties as well as the mode of operation of the pipeline. For example, sewage in a private house works in a pressure-free mode, so the usual bell-fitting dock fits.

But in the case of the installation of the heating system will require something more reliable. The following are the most common methods.

Threading

It can be considered a classic method that was used decades ago.

The instruction hasn't changed at all since then, you need to act in the following sequence:

- fitting is performed and a mark is made on the pipe to which it will be necessary to cut the thread;

- Actually, carved. For convenience, the pipeline needs to be fixed in a vice, the slightest bias of the plate when cutting threads can cause leaks in the future;

- underwinding is performed - a linen thread or any synthetic sealant is simply wound onto the thread. Its price is minimal, and the tightness of the joint increases significantly;

- the thread is screwed on the fitting. Threaded connection of pipes belongs to the category of plug, which facilitates the dismantling and cleaning of the pipeline.

Note! Threading slightly weakens the cross section. Therefore, it is necessary to avoid as much as possible mechanical effects on the joint.

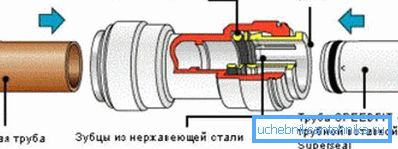

Using Collet (Clamping) Fitting

The use of such a fitting allows you to even connect pipes from different materials. The connection is obtained detachable, which can also be attributed to the advantages of using collet fittings.

When using a collet connection of pipes for joining different materials, on the one hand, the tightness of the joint is achieved by means of a cap nut and compression ring, and on the other hand, by means of a collet.

Docking is performed in the following sequence:

- a cap nut and compression ring are put on the pipe (in this sequence);

- then the nut is tightened, the ring is deformed and tightly presses the end of the pipeline to the end of the fitting;

- on the other hand, the tube is simply inserted into the collet and retracted until it stops. The design creates sufficient pressure on it, so that the strength of the joint is guaranteed.

Mobile connection

Sometimes standard fittings do not allow docking at the desired angle. In this case, you can use a swivel pipe. This method of joining will be useful also by the fact that the angle of inclination can be easily changed without dismantling a part of the pipeline.

Such fasteners are sold already assembled, and the mobility is achieved due to an unusual construction of the socket. The bell itself is quite wide, and the part of the pipe that is placed in it has a spherical shape. The space between the end of the pipeline and the inner surface of the socket is filled with rubber inserts and a layer of lubricant.

Note! The resource of this type of docking is limited (the manufacturer indicates the guaranteed number of turns), so you should not bend or unbend the pipeline unnecessarily.

As for the angle of rotation, it is usually in the range of 40-50 ?. Large turning angles complicate the design of the turning part and jeopardize the tightness of the joint. Transporting corrosive liquids greatly shortens the life of the hinge.

High pressure pipe

It is hardly necessary to work with high pressure at home (pressure in the water supply system cannot be considered as such). But in the industry quite often liquids are transported under considerable pressure, which puts forward more stringent requirements for the joints.

Pipe fittings of high pressure with a large number of turns and fittings installed in these places will have a low degree of reliability compared to a pipeline with a minimum number of turns.

To solve this problem, pressure hoses are often used - high pressure hoses. Externally, such a sleeve looks like an ordinary rubber hose with metal fittings on both sides.

Despite its appearance, the design of RVD is complicated. The sleeve consists of an inner layer of special rubber, and the strength is achieved by the power frame made of metal threads. Often there are several such power frames.

The main advantage of such sleeves is that the turn is smooth and the resistance to the flow of fluid is minimal. The ends of the hoses are attached to the pipeline with metal fittings.

American - simplicity and reliability

Any types of pipe connections should be reliable and, if possible, allow the pipeline section to be dismantled as quickly as possible without dismantling the rest of the pipeline. For these parameters, an American out of competition.

To dock 2 sections of the pipeline in this way, you will need 2 threaded fittings (one of them with a restrictive collar), a rubber gasket and a cap nut. At the ends of the pipeline should be internal thread.

American pipe fitting is performed in the following sequence:

- the part with the external thread is screwed onto the pipeline section with the internal thread;

- after that comes the turn of the part with the collar, you need to put on it a sealant and a cap nut, after which the fitting is also screwed onto the pipe;

- after that, it remains only to tighten the flare nut to the external thread of the return fitting.

Note! Unlike most other types of docking, to dismantle a part of the pipeline, it is not necessary to disassemble it entirely. The entire assembly / disassembly process is performed with just one nut.

Tavrovoy connection

T-pipe joints can be either at a right angle or at an acute angle; it is necessary when another pipe needs to be inserted into an existing pipeline. An example is a tie-in sewer pipe going from the apartment to the riser. You can provide a tie-in in two ways - using special fittings or welding (if the pipes are metallic).

As for fittings, for this we use tees and crosses, these elements allow you to create a complex knot. Such a connection with a tee can be performed by any of the methods described. Can be used crimp fitting, welding PP (in the case of polypropylene pipe), socket connection (if we are talking about sewage), etc.

Inset metal pipes using welding is rare and quite difficult for a novice plumber. The main problem here is to correctly mark the cutout on the pipe into which you need to crash and on the end of the pipeline that will join.

To solve this problem, you can use special templates, in which, depending on the diameter, there are curves that mark the contour of the cutout, you can also use special marking programs.

Note! If the cuts do not match perfectly, then the cracks will have to be baked with pieces of metal, and this will adversely affect the tightness. Therefore, the markup should be focused on.

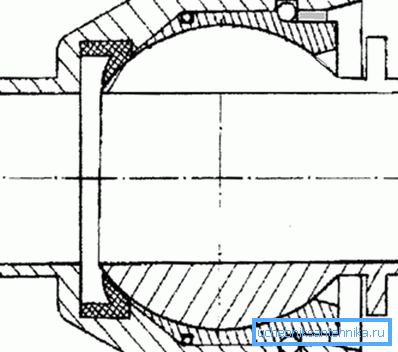

Nipple joint

The nipple connection of pipes belongs to the class of detachable and consists of the actual fitting (a conventional threaded sleeve and a restrictive shoulder), a sealing ring and a cap nut.

The order of joining sections of the pipeline in this way somewhat resembles an American:

- On the fitting (threaded sleeve), you need to put on the sealing ring and the union nut;

- after that the fitting is screwed onto the threaded pipe;

- to complete the connection, it remains only to screw the union nut onto the coupling or the end of another pipeline.

This method is often used when you need to embed a measuring device into an existing system. The fitting is convenient because there are almost no restrictions on the diameters of the elements to be joined; to ensure tightness, it is enough to simply select the required diameter of the choke fitting.

Grouting connection

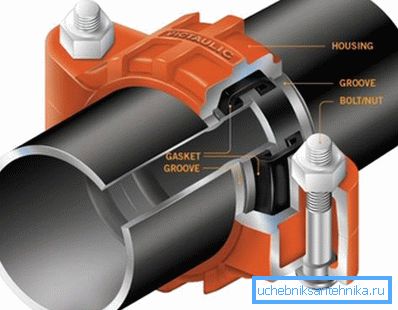

This type of connection can be considered one of the simplest. Grooved connection of pipes belongs to the category of welded detachable types of docking of the pipeline.

Gruvlok - the usual clamp that allows you to quickly combine into one whole 2 pipes. The design of this element is quite simple - a plastic case inside which is a rubber seal and bolts on both sides. Tightening the bolts creates the necessary pressure, the rubber cuff deforms tightly against the surface of the pipeline, thereby ensuring the tightness of the joint.

Loose pipe connection is the best option from the point of view of pipeline maintenance. At any time, the bolts can be loosened, the clamp is removed and the damaged pipe section can be cleaned or replaced.

The construction of some grooves is a bit complicated and has a protrusion around the entire circumference. In the pipeline at a certain distance from the joint there should be a groove; when docking, the protrusion on the groove enter this groove, providing additional joint strength.

In conclusion

No pipeline can be laid without encountering the problem of joining individual sections. You will have to choose between a variety of options, each of which has its own advantages and disadvantages. The article provides a brief overview of popular pipeline docking methods.

Beginner plumber with the help of this information will be able to determine the best option for installation. The video in this article discusses some types of detachable connections.