Ppr pipe - features and application

PPR pipes or PPRS (abbreviation of the same material) are better known as polypropylene pipes - this is perhaps the most common type of plastic pipes. Their main advantage is the ability to withstand high temperature and high pressure.

Next, we take a closer look at the features of such pipes, their types and installation technology.

General information

The main material for PPR pipes is polypropylene, and not clean, but with the addition of ethylene (also read the article Exhaust pipes - what should be this necessary element of ventilation).

This additive affects the material as follows:

- Increases elasticity;

- Improves mechanical properties;

- Reduces the consumption of propylene, thereby reducing the price of products.

But, most importantly, the melting point of this plastic is +176 degrees Celsius, so that boiling water can be run through the pipeline without worrying about its safety. Therefore, often use pipes PPR for heating.

In addition, as mentioned above, they tolerate high pressure well - they can be operated at a temperature of 95 degrees and a pressure of about 10 atmospheres. For comparison, metal-plastic pipes at the same temperature of a liquid are able to withstand a pressure not exceeding 6 atmospheres, and, their temperature margin is only 113 degrees.

For this reason, serious construction organizations work only with “polypropylene”, despite the fact that a special soldering iron is needed to install such a pipeline.

Merits

Among the advantages of these products are the following points:

| Corrosion Resistance | It distinguishes them favorably from metal counterparts. This quality increases the life of the pipeline several times. |

| Low hydraulic resistance | Due to this property, the pressure loss is minimal. |

| Resistance to chemical and biochemical factors | This property also increases the durability of the pipeline. |

| Environmental friendliness | The material from which the pipes are made does not adversely affect the human body. |

| Frost resistance | At low temperatures, the pipeline expands, but does not crack. As a result, the integrity of the system is not violated. |

| Easy installation | You can assemble the pipeline very quickly. However, as mentioned above, you need a special soldering iron for pipes PPR. |

| Low weight | In this regard, transportation and installation does not cause any problems. |

| They have a low thermal conductivity. | Due to this, the liquid flowing through them loses much less of its heat than in the case of metal pipes. In addition, they do not form condensate. |

| The smoothness of the inner walls | They do not settle sediment, which also increases the life of the pipeline. |

In addition, it should be said that there are special fittings of various types on sale. Due to this, the distribution of SPR water by pipes can be performed of any complexity.

disadvantages

As for the shortcomings, there are two serious points that should be paid attention to:

| Large thermal expansion | This indicator can be up to 5 cm per meter of pipe. Therefore, when installing the pipeline you need to use compensators. |

| Oxygen permeability | For water supply systems, this property does not play a special role, but for a heating system, this is bad. True, pipes with solid aluminum reinforcement are devoid of this drawback. In addition, their coefficient of thermal expansion is lower by almost 70 percent than other CPD pipes. |

Types of CPD pipes

Wall thickness

First of all, the products differ in wall thickness, on which the maximum allowable pressure inside the pipeline depends.

There are such types of them:

- pipe PPR - 20 atm .;

- 16 atm .;

- 10 atm

Reinforcement

Another important difference is the type of reinforcement, which prevents deformation and allows to maintain hardness even at high temperatures of the flowing fluid.

So, the products are:

- Single layer - no reinforcement.

- Fiberglass reinforced - such reinforcement increases the strength and reliability of the product, but at the same time increases its weight. It is possible to distinguish from their features that the PPR pipe reinforced with fiberglass does not require stripping before installation.

- Reinforced with aluminum - similar reinforcement gives the product durability, but is not displayed on its mass.

Aluminum reinforcement is of two types:

- solid;

- perforated.

As mentioned above, continuous reinforcement reduces the oxygen permeability of products and the coefficient of thermal expansion.

- Consisting of more than three layers - such pipes have a supplemented layer of hot melt adhesive and are the most durable.

Tip! It is very simple to distinguish a reinforced product from an unreinforced product, just look at its cut - the PPRS reinforced pipe consists of several layers.

Diameter and color

PPR pipes come in a variety of colors, however, their properties are independent of color. The exceptions are black products that are most resistant to UV light. As for the section, the pipes and fittings PPR are with a diameter of 1.6 to 12.5 cm

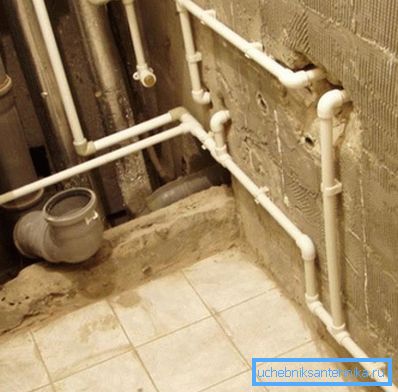

Pipeline installation

The installation manual for the pipeline is as follows:

- First you need to turn on the soldering iron to get the working temperature.

- Next you need to prepare the pipe and fitting that will be soldered.

- After that, both parts must be inserted into the soldering iron connectors and wait until they soften.

- Then the pipe and fitting must be pulled out of the soldering iron and connected to each other with their hands.

- Details in this position need some time to hold until they are completely set.

If all actions were performed correctly, then in the end you will get a solid welded seam. Thus, soldering pipes PPR is nothing complicated. The most important thing is to do the work carefully, avoiding errors in the measurements.

Tip! Before proceeding to the installation of the pipeline, it is advisable to practice on trimming pipes. Having filled your hand, you can take on the main work. This will avoid marriage in the first stages of the installation of water supply, and thereby save material.

Conclusion

Pipe PPR have several advantages over metal or metal-plastic counterparts. Therefore, at present they are most popular in the construction of domestic water supply systems and heating systems (see also the article Viniplast pipe - features and scope).

Properly performed their installation will allow you to forget about replacing the pipeline for decades. From the video in this article, you can get more information on this topic.