Ppu insulation for pipes to reduce heat losses inside the

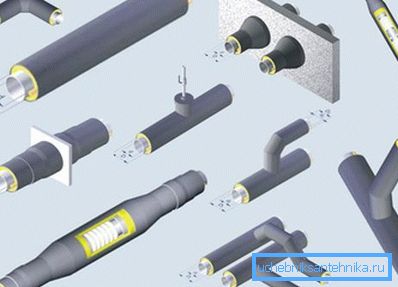

Some communication systems need maximum heat retention, so innovative innovations are being developed all the time. One option is the production of pipes in foam insulation. Such products can reduce heat losses by about 40 percent, as well as serve a long period of time.

Shell Material Consideration

The product is based on polyurethane foam belonging to the category of gas-filled plastics, which are formed by the method of foaming with the subsequent solidification of the liquid composition. The gas phase accounts for approximately 98 percent of the total volume of the material, therefore the thermal insulation characteristics are high. The following is a comparative table with other analogues.

| Material | Service life in years | Density in kg / m3 | Coefficient of thermal conductivity | Temperature range |

| Hard PU | thirty | 35-200 | 0,019-0,035 | -80- + 180 |

| Styrofoam | 15 | 15-35 | 0.043-0.064 | -80- + 80 |

| Mineral wool | 5-10 | 15-150 | 0,052-0,058 | -40- + 300 |

| Foam concrete | ten | 250-400 | 0.145-0.160 | -30- + 120 |

Note! From the table above it can be seen that the use of the material provides an opportunity to increase to some extent the useful volume of manufactured products.

The main list of advantages

- When using steel pipes in PU foam insulation, the timing of installation work during the laying of communications is noticeably reduced, since there is no need to set up pipe boxes.

- Thanks to the heat-insulating shell, the elements become resistant to environmental influences.. Their lifetime is significantly increased (up to 30 years).

- Reasonable price makes it possible to use products with thermal insulation in various branches of construction., Moreover, the amount spent is paid off not only with a long service life, but also with the absence of additional work.

- Pipelines with the presence of such a shell are able to retain heat well in the system, thanks to which the energy costs for heating the internal environment are greatly reduced.

Manufacturing process

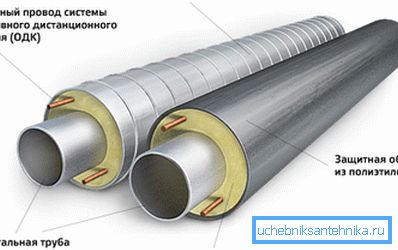

Pipes in PPU of isolation in accordance with GOST 30732-2006 are made, where the basic requirements to production are presented. First, steel products are trained to improve adhesion. They are placed in the heating chamber, after which they enter the shot blasting unit.

Cleaning with special brushes is performed there. This treatment allows you to enhance the ability to adhere to the components of the heat-shielding shell. After this, an assembly is performed in which the pipe is placed inside the insulation and fixed. Along the edges are left bare ends, to be able to carry out welding.

Assembly

Typically, pipes with PU foam insulation are used to lay the heating main in various buildings in order to heat or supply hot water. However, in some cases, the elements are used by individual developers, who heat additional buildings in the suburban area and the like. Therefore it is worth considering the installation process.

General provisions

- Isolation of joints start after testing welds non-destructive method. As an alternative method, hydraulic tests can be performed.

- Insulation of polyurethane foam pipes at the joints should be made at temperatures above -15 degrees. In case of precipitation, it is allowed to perform work only under a special shelter in order to prevent the penetration of moisture.

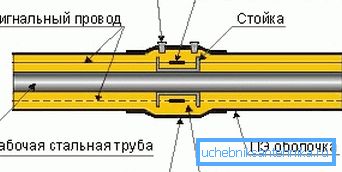

- When constructing a heating main with the presence of a remote control system for the state of the shell, it is mandatory to take into account the specialized instruction for connecting conductors.

- On elements with a diameter of more than 273 mm, the thermal shrinkage of the couplings is carried out using two gas burners at once.

Main works

To do the installation yourself, you need to have some knowledge in the field of welding of steel pipes. As for the other operations, they are quite simple.

For familiarization, the following is the procedure that should be followed to join the elements and insulate the joints.

- Directly before welding, a coupling is installed. The protective film is not removed until the process of closing the joints begins. Circular welding is in progress.

- The ends of the insulation, as well as the surface under the coupling are thoroughly cleaned from dirt. The steel pipe is brushed for metal to eliminate a completely loose layer of rust.

- The protection layer is removed approximately 15–20 mm, after which the signal conductors are installed, allowing control to be carried out at a distance. Control measurements are made.

- The polyethylene shell is degreased with a solvent. The part from the end is processed by 15-20 cm. After that, sanding is carried out with sandpaper and re-lubrication with a degreasing compound.

- Using a tape measure and a pencil, marks are made to mark the edges of the connecting piece. This is necessary in order to perform the centering. When drawing a marking it is impossible to apply chalk.

- The clutch is unpacked in a specific way. Its outer part should be on the polyethylene sheath of the element. Movement will occur on the inner surface.

- A hole with a diameter of 25 mm is drilled in the upper part of the connecting part, and the distance from any edge should be 150 mm. Surfaces on both sides are heated by a burner.

- On the heated base around the perimeter is mastic tape. About 10-15 mm recede from the pans. The overlap of the strip should not be less than a centimeter.

- The clutch gently slides onto the joint in accordance with the marking. The edges of the element are seated using the soft flame of a propane torch.

- The joint is insulated, for which a specially prepared mixture is poured into the hole. At the last stage, a polyethylene plug is installed.

Note! Tightness control before pouring the composition is carried out by pressing the pipes, when using a special device, air is pumped under a certain pressure.

Final part

Having studied the above information, it can be understood that the pipe in PU foam insulation is the ideal solution for arranging thermal routes that need perfect protection from cold and other influences. More detailed information about modern products with finished insulation and installation work is presented in the video in this article so that novice masters can fully understand the installation process.