Production of plastic pipes: from raw materials to the

Due to the expansion of the sales market, the production of plastic pipes in Russia can be quite regarded as a fairly profitable business. Naturally, before investing in such an enterprise, you should at least familiarize yourself with the features of the production scheme, as well as examine the demand and assess the potential profitability.

Features of plastic pipes

Polymer pipes made of various materials (polyvinyl chloride, polypropylene, polyethylene, composites, etc.) are widely used today.

As a rule, such parts are used for arrangement:

- Water pipes.

- Technological pipelines.

- Sewer systems (internal and external).

- Heating systems, including "warm floors".

Among the reasons for the popularity of plastic pipelines are the following:

- Good performance.

- Durability.

- Simplicity in processing and installation.

- The wide range allowing to pick up products practically for any purpose.

- Affordable price.

Every year, experts note an increase in the volume of the market for such products, and therefore in the near future it is possible with a certain degree of confidence to predict an increase in consumer demand.

Based on these considerations, manufacturers of plastic pipes in Russia are gradually increasing their production volumes. So if you want to get your share of profits in this segment of the business, then you should hurry, while the niche still holds new market players.

Technological process

Equipment

One of the advantages of manufacturing pipe products as a business is the relatively low complexity of the manufacturing process itself. At the same time, of course, the investment will be considerable, but high profitability with proper organization of the process will quickly “go to zero”, after which the line will start to bring net profit.

For a start, all the equipment can be placed in the workshop with an area of 50 to 100m2. It is also desirable to allocate separate rooms for the storage of raw materials and finished products. Over time, it is possible to expand production, for example, the installation of several more lines or equipment for the manufacture of more complex products.

Equipment for the production of plastic pipes includes:

- Bunker, in which the mixing of raw materials.

- The drive feeding technological polymer at the stage of molding.

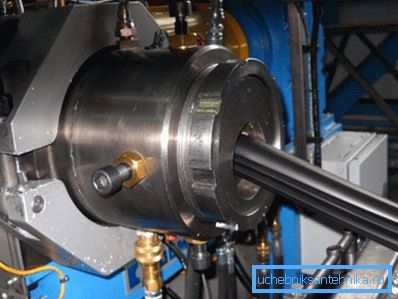

- The extruder, working on the principle of the grinder: polymer mass is extruded through a calibrating plate with holes corresponding to the diameter of the pipe (die).

- Device for pulling and calibrating products.

- Cooling bath

- Cutting mechanism (guillotine or circular saw).

Note! This set is suitable only for the manufacture of the most simple products. For example, the production of metal-plastic pipes requires the installation of a more complex extruder, which automatically combines foil liners and polymer blanks, and for the manufacture of fittings a molding machine with a set of dies is necessarily needed.

Raw material

The selection of raw materials depends entirely on what kind of products you plan to produce and sell.

Usually, the basis of the purchase is granulated polymers:

- Low-cost polyethylene is cheap enough. Its cost ranges from 30 to 40 p / kg.

- A few more expensive purchase of granulated PVC - about 55 p / kg.

- Polypropylene copolymer is considered the most expensive - 60 p / kg and above. At the same time, pipes from such raw materials are obtained most durable, so from the point of view of financial efficiency, the choice will be quite justified.

- In addition to the basic materials will also need funds for reinforcement - aluminum foil and fiberglass.

It should be noted that when a single line is fully loaded, the consumption of materials ranges from 80 to 150 kg / hour. That is why we recommended above to allocate a place for storing a stock of material for at least two or three days of work.

Note! It is advisable to conclude an agreement for the supply of raw materials with one enterprise, since the replacement of materials is usually accompanied by reconfiguration of equipment, and it is rather difficult to do it yourself. So it is better to avoid the cost of attracting specialist fitters.

Basic operations

Technological instruction for the manufacture of tubular products by extrusion method includes the following steps:

- Polymer pellets are moved to the extruder feed hopper using an auto-feed device.

- The screw inside the extruder distributes the raw material and ensures that it is fed into the so-called material cylinder.

- Heaters installed on the outer surface of the cylinder, provide the melting of raw materials, after which a tubular billet is formed.

- Passing under pressure through a die plate (the extrusion process itself), the polymer takes the form and dimensions of a pipe.

- Next, the workpiece passes the calibration of the outer diameter. At the same time, the wall thickness is adjusted by changing the pulling speed.

- The molded and calibrated pipe enters the cooling baths, where its temperature is equalized and reduced to standard values.

- At the last stage, either trimming the pipes to size or winding a certain area into the coils is performed. Usually this process is controlled by the meters in automatic mode.

Note! Here is the simplest flow sheet. Introduction to the composition of the wall of the reinforcing belt repeatedly complicates the manufacturing process, because usually such pipes are made on professional equipment under the guidance of an experienced technologist.

Finished products must pass a quality control. During this operation, each batch of pipes is checked for internal and external diameter, wall thickness, the presence of deformations, etc.

Conclusion

To buy a machine for the production of plastic pipes is not even half the battle. This business will be effective only if you can choose the right raw materials and start production. And this will only be possible when you thoroughly study both the technology and the requirements for the finished product.

So if you decide to engage in this type of activity - start by watching the video in this article.