Production of polypropylene pipes - features of the

If earlier Western manufacturers of polypropylene pipes were valued much higher than domestic ones, then every year this difference becomes less and less. New modern lines for the production of this group of products appear in Russia, and with the observance of technology and the use of good raw materials, it is possible to achieve quality at the level of world standards.

What is necessary for the organization of production

Before you decide on the feasibility of a business project, you must carefully weigh all the nuances and features of the type of production. As for the variant we are considering, the following factors are important:

| Financial opportunities | The price of equipment can vary in a fairly wide range, but you should not save on quality in any way. Any breakdowns in the process of work mean downtime and, as a result, a significant loss of profits and the cost of repair activities. |

| The presence of the building | Experts calculated that a space of at least 100 m is necessary for the effective functioning of production.2. This figure may vary depending on the characteristics of the equipment, so it is best to consult with the manufacturer of the line and find out its recommendations. |

| Features of the range | No instruction will tell you which kind of polypropylene pipe will use more with millet in your area. It is necessary to carry out marketing research in order to study the structure of the market, its fullness with certain products and the presented price offers. |

| Payback period | This indicator depends on many factors. Therefore, it is not recommended to make calculations with your own hands, it is better to entrust it to qualified specialists, who will more accurately determine the approximate period for which the line will fully justify itself and begin to make a profit. |

Tip! A very important factor, forgotten by many business organizers, is the availability of sufficient space for storing raw materials and finished products; it is unlikely to be able to organize fruitful and efficient work without a spacious warehouse.

Features of the process

Equipment for the production of polypropylene pipes - this is not one machine that performs all the necessary functions. It will take a whole range of special devices that should work in a single system.

Extruder

There are several types of fixtures on the market:

- Screw type, the principle of operation of this group is simple: the auger crushes the incoming raw material and feeds it further for melting.

- Without screw. In them, the main working part is a special disk.

- Combined systems are a system in which there is a disk and a screw.

Note that the most popular option is the first because of its simplicity, efficiency and high reliability in the process.

A machine for the production of polypropylene pipes may have several screws, its work is carried out as follows:

- Initially, the raw material is poured into a special bunker, its capacity must be sufficient in order not to add raw material too often.. In the most advanced models can be provided for the automatic feed of raw materials.

- Next, the granules are fed into the extruder, where under the influence of high temperature, they melt, and the mass is given a uniform consistency using a screw.

- Next, the mass is passed through the forming head of the extruder, which sets the parameters of the future product. The quality of the polypropylene pipes coming out of production depends on how well the head is used.

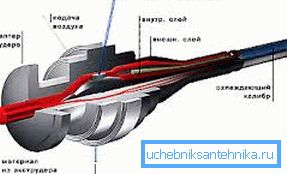

Bath calibration

The pipe left the extruder is not yet a finished product, in order to give it all the necessary characteristics it needs a cooling and calibration bath, it works as follows:

- Hot billet is served in a special device equipped with a cooling system. In addition, the product is affected by increased pressure to preserve the physical parameters of the pipe, the rapid cooling prevents disruption of the shape and allows for the highest quality.

- Next, the product passes through the calibration form, it is there that the final parameters are given to the pipe. Thanks to this node, all elements are obtained in exactly the same size with a smooth surface without sagging and scoring.

Note! It is best to buy a calibrating bath, all working elements of which are made of stainless steel, this ensures easy sliding of the pipes and long-term operation of the mechanism without breakage.

Other important devices

Undoubtedly, the equipment examined by us is basic, but the line for the production of polypropylene pipes will not be able to work without the following devices:

- The pulling and cutting device, this part of the line is responsible for the continuous movement of the pipe and cutting it into pieces of the desired length. Most often, the equipment has a meter that measures the pipe very precisely and cuts it as specified by the program.

- Depending on what type and diameter of the pipe is produced, you will need either a winder (which will assemble the product into coils and store them), or a stacker that will fold large diameter articles.

Conclusion

The production of polypropylene pipes belongs to the promising areas of production, since every year the demand for this group of products will only increase.

The video in this article will vividly show some features of the technological process.