Production of profile pipe: analysis of the technological

Today, the production of profile pipes is in demand in almost all branches of technical activity and therefore there is a demand for it in civil and industrial construction, the automotive industry and aircraft construction, in the production of furniture and in the manufacture of decorative structures.

This, of course, is far from being the entire list of areas where such material is used: its purpose also depends on the steel grade, cross-section configuration, coating and sizes.

Of course, we will not be able to tell you about everything in the smallest detail, but provide you with a schematic overview of the main operations.

Production technology

Main ways

The most common is the welded manufacturing technology:

Note. According to GOST 8645-68 (modified and supplemented 01/07/2010), the steel tubular profile is made of low-alloyed and carbon sheet steel (strips), which as usual comes in rolls, as required by the instruction.

- The blank, which is cut from strips, is processed on a specialized machine that is designed to bend sheet metal.

- The resulting profile of square or rectangular cross section has a longitudinal joint of the edges of the strip, which is cooked by the welding machine along the entire length in the environment of protective gases or inductor welding (depends on the requirements to the product). For seam strength, compression is enhanced by rollers.

- After that, a burr (protruding molten metal) remains, which is removed with the help of a cutter (the whole process can occur either in the hot or in the cold state of the metal).

- Also, the billet can be supplied to the rolling mill in the form of a pipe, where it is given the required square or rectangular shape by rollers.

Cold and hot deformation

The finished product can be hot-deformed and cold-deformed, with the first option implying tempering (gradual cooling).

During hot deformation, the price of the profile increases with the quality - such structural material has less internal stress, which, in turn, allows it to retain its original shape during storage and operation.

- For cold deformation, the equipment for the production of shaped pipes is small, therefore, the area of production workshops is reduced. This entails lower prices for finished products, as it produces less cost.

- These lines are very popular and the market, of course, responds with a large offer, therefore, there is always the opportunity to purchase machines of different capacities and from different manufacturers, including both domestic and foreign.

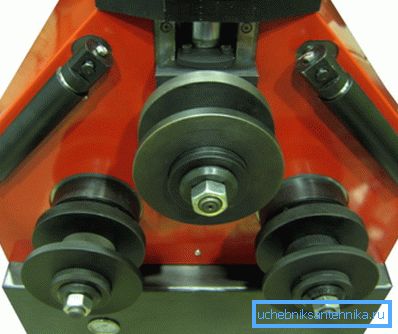

- As a rule, such equipment is a set of rollers, which give the desired section to the workpiece (deformation process), and the installation capacity is usually sufficient to deform seamless pipes.

- But cold processing has a significant drawback - it is impossible to obtain a high-quality profile that will withstand serious loads.. Therefore, such material is not used for various supporting structures - this is a segment of furniture production and decorative ornaments.

During hot deformation, the pipe after heating is cooled by the emulsion and the forming stage begins - it enters the rolls, which press on it from different sides and give it a shape that is specified by the program.

- The quality control of the weld is made by the vortex flaw detector., which compares the electrical and magnetic properties of the metal, changing under the influence of physical defects and chemical composition of the seam.

- After that, the profile is cut into pieces, moreover, this is done not by hand, but automatically, determined by the setting of the production line, but the end of the cycle is the heat treatment of the pipe profile.

- The pipe is heated to the desired temperature and released. (gradually cooled) - this process allows you to relieve internal stress, which in any case is formed during deformation processing of the profile.

Machine selection and production organization

For the serious development of the production of the production of the profile pipe, you will at least need:

- Profile bending machine.

- Automated welding line.

- Machine for deformation (transformation by rolls of the round form).

- Device for fragmentation (cutting).

It is very important to monitor the quality of production and for this you will need a vortex flaw detector and a worker who can take readings from it.

Note. Your business plan for the production of profile pipe in the first place, will depend on the availability and size of production areas. The larger they are, the more powerful equipment you can install there.

Competition in such a production is quite tough, so you should in no way neglect the quality of the products. To ensure this quality, the finished pipe must be heat treated and then released.

With an increase in the quality of products for it, naturally, the demand grows, despite the fact that its retail price rises, therefore, this way you will be able to compensate the costs invested in production much faster. After all, for the manufacture of goods with a low price and low quality you will only have enough rolls, but so you lose your reputation, and then demand will inevitably fall.

Conclusion

Today, there are quite well-known manufacturers of profile pipes in Russia, among which are references to Altima CJSC, Areal TD LLC, Armispromstroy CJSC, WELD-Metiz LLC, Veteran VET and others. Despite the abundance of enterprises, demand is still there, and you will be able to join the competition in ensuring the quality of production (see also the article Production of polypropylene pipes - features of the technological process).

The video in this article will help to understand the nuances and get an idea of the scope of the work ahead.