Profile pipe 100 per 100: understand the technical features

Pipes of profile type are widely used in various spheres of human life. Depending on the area in which the product is used, the required size, shape, section type, wall thickness, steel grade from which the production was carried out is selected. The only factor determining the similarity of products of various dimensions and technical characteristics is the method of selling such products.

The price of one running meter of materials of different properties is determined depending on what the weight of the pipe is 100 100. Next, the article will present the factors affecting this indicator, and the method of calculating the mass will be described.

Why you need to know the weight

In order to acquire a sufficient amount of material for solving the tasks set, it is necessary to know the exact number of kilograms in 1 meter.

Parameters that affect mass

Note! Mass is an indicator that directly depends on how much raw material was spent on the manufacture of a product, thus, the weight of the pipe 100x100x3 will depend on the amount of metal consumed for its production.

In addition to such factors as the mass of the raw material, the weight of the profile material will also be affected by such characteristics as:

- The width of the walls;

- The density value of the material that was selected as a raw material;

- The shape of the finished product;

- The thickness of the walls of the profile pipe is 100 per 100.

In this way, the weight of a 100x100 square tube made of aluminum and steel will be different even if the overall dimensions are absolutely identical.

Why do you need to know the mass

Not only the determination of the cost of purchased products is the reason that it is necessary to know the weight of 1 meter of pipe 100x100x6. This need is also associated with the definition of the operating conditions of such shaped materials from various types of metal.

A scope of similar production with square type of section is the construction sphere, and is more specific:

- Production of powerful welded frames;

- Creation of various building systems and structures;

- Furniture manufacture;

- Creating supports for the installation of the gate;

- Production of car bodies;

- Shipbuilding, etc.

It is this scope that determines the fact that the design engineer, starting from such a parameter as the weight of 1m pipe 100x100x3, calculates all possible loads:

- which during operation can withstand the profile frame;

- which this framework itself will create on the underlying structures.

Knowledge of this indicator allows you to produce the highest quality design facilities for various types and purposes. Competently made calculations will guarantee the absence of threats of destruction.

Pipe 100x100x5 - the weight of which must be able to determine during the design, and on which such characteristics of the structure as physical and mechanical properties will directly depend.

Based on the weight of various types of products, designers select the most suitable for the construction of a particular structure, giving it the optimal characteristics.

The required weight of materials used in the manufacture of a particular design, is selected depending on the purpose of the finished frame and features of its operation.

Note! Under these conditions, the more complex the projected framework will be, the more difficult the challenge will be for the architects involved in the design. Considering the mass, they will have to calculate the strength of the frame, resistance to bending, as well as a huge number of important and significant characteristics before starting to work.

The specialist selects materials related to this class, which will allow them to fully perform all the assigned tasks and functions, while coping with the retention of the entire structure of the created object.

With an accuracy to determine the weight of the pipe 100x100x6 in 1 pm quite difficult, for this you need to have some knowledge and have the skills of making calculations in practice.

Council Weight is an objective criterion for determining the class of material, and the higher this class, the greater the load it can withstand during operation.

How to determine the mass

Profile metal products usually have a standard cross-section of rectangular or square shape. This type of product is endowed with the most optimal combination of indicators such as strength and cost. The most common sizes are 20x40, 40x40 and a 100x100 square tube.

How is it possible to determine the mass of 1 m of products, for example, with dimensions of 100 per 100, in order that this indicator could be included in the technical documentation for the object under construction?

Instructions for determining the value of this parameter for standard profiles differ depending on one indicator, even in cases where they have the same wall thickness and cross-sectional area.

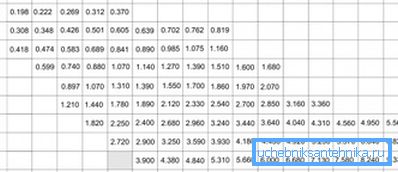

Note! Even the value in kilograms of linear meter, which the material possesses according to the table according to GOST, may differ from the real indicators due to the fact that manufacturers can produce their products corresponding to certain tolerances.

In order to calculate the exact mass of the material you need to use a specialized formula that will have some slight difference from the formula according to which the mass of products with a standard circular cross section is determined.

The weight of such a product, such as, for example, a pipe 100x100x3, can be determined using a mathematical formula that has the following form:

MP = Sx2x (A + B) x ?, where:

- S is the wall thickness of the product;

- A - profile width;

- B - profile length;

- ? - The density of the material used for manufacturing.

Note! The presented formula is used only in cases where the designer does not have the opportunity to use the specialized tables used to determine the mass, which the pipe has 100x100x8 or materials of other sizes.

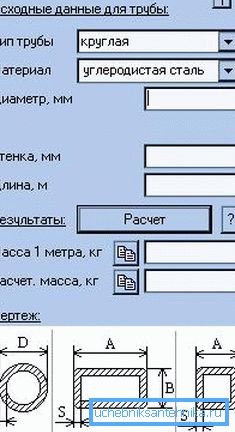

In addition to the table and the presented formula, you can find out the value of the mass of the profile material using specialized software. Moreover, these programs work in such a way that you can find out the parameters of not only products with a rectangular or square section, but also of any other form.

As a rule, the initial data for a computer program to cope with the task of weight indicators is the following list of characteristics:

- The length of the profile type of the product;

- The type or shape of its cross section;

- Wall thickness options.

Tip! In addition, you will need to specify the type of raw materials used to manufacture the material from the options identified by the program.

The mass of pipes, most often used in practice

In practice, not all profile sizes are in demand. Mostly used a small number of their species.

Let's take a look at the severity values of some of the most popular:

- Steel product section in the form of a square, the side of which is equal to 20 mm,

- Edge thickness 0.1 cm - 0.62 kg per running meter;

- Edge thickness 0.15 cm - 0.93 kg per running meter;

- Rib thickness 0.2 cm - 1.225 kg per running meter;

- Steel product section in the form of a rectangle with the sides width - 20 mm, length - 40 mm:

- Edge thickness 0.15 cm - 1.410 kg per running meter;

- Rib thickness 0.2 cm - 1.853 kg per running meter;

- Steel product of square section, the side of which is equal to 40 mm:

- Edge thickness 0.1 cm-1.24 kg per meter;

- Edge thickness 0.15 cm - 1.849 kg per meter;

- Rib thickness 0.2 cm - 2,447 kg in running meter;

- Steel pipe 100x100x6 - 17.22 kg in running meter.

Finally

Pipes of profile type 100x100 or other sizes are, of course, an excellent basis for the construction of frame-type buildings, as well as reliable construction. But in order for the structures created from them to be reliable and durable, it is necessary to calculate the loads based on the weight of the material used.

And the video in this article will reveal to you the secrets of not only how to choose the necessary product, but also make the installation of the frame.