Profile pipe 40x20 mm - characteristics and application

The industry makes pipes of different section - round, rectangular, square, oval. In this case, the “music is ordered” by the consumer who feels the need for them. And thanks to its qualities, steel profile pipe has long become an indispensable element of most metal structures.

Production of specialized products

The process consists of two technological operations:

- A round billet produced on a rolling mill is pressed.

- The tape profile is being welded, which is formed on a special machine..

The first option today is practically not applied. This is due to the high cost of seamless steel tubes compared to welded.

Below we will tell about two technologies in more detail:

| Seamless |

|

| Welded |

|

The latter method is much cheaper to work, and the products are not inferior to the seamless in strength characteristics, since welding reduces this parameter only by 5-10%. In addition, the material retains its natural plasticity.

In addition to conventional structural steel, its alloyed grades are also used in production. An example is a profile stainless steel pipe, alloyed with chromium. From this, the cost of the pipe 20x40 increases.

Assortment

Product classification is based on the following parameters:

- length;

- cross section;

- profile type.

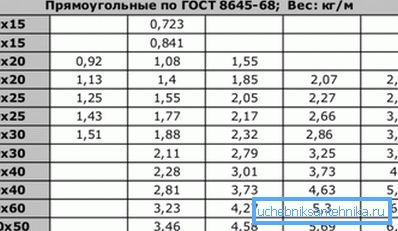

Also, they often take into account the grade of steel and the fact of finishing heat treatment. The length of the products is consistent with GOST 13663-86, where it is indicated that the shaped tube is produced in the form of measuring segments in the range of 1-12 m. The section is defined by GOST 8642-68, in which the parameter is divided into 36 standard sizes.

Profile type is divided into:

- rectangular;

- square;

- oval.

Strength properties depend on the above parameters, which affects the range of use of these products.

Where apply

The main area of use of profile pipes is the manufacture of metal structures.

Here it acts as a decorative, loadable or loadable decorative element.

- They can be used as loadable and decorative elements - sofa legs, table frame, stair railing, or as components for metal decoration. Designers prefer the profile hire of stainless steel or chrome products, which are used to form the visible frame of the furniture. They can also be used to imitate wrought decor on the stair railing, in the fireplace grates and other decorative elements.

- Due to the fact that the weight of a 40x20 square pipe is small, as well as its plasticity and strength, it provides the necessary rigidity of the frame metalwork and reduces its weight by 30-40 percent or more. At the same time, the hollow profile tube is easily bent into the desired workpiece without the use of thermal heating. To do this, use special equipment - pipe benders for bending pipes.

Tip: the characteristics of the profile tubes allow you to construct the frameworks of any complex shape.

- In construction, they are used as a beam or supporting frame. In this case, the profile of a rectangular shape is valued higher than the channel or I-beam, since the weight of the product is less, and the strength is almost the same.

Tip: You can use the cavity inside to lay a power line or conduit.

Steel rectangular shaped pipes are used in the form of frames for interfloor ceilings, roofing systems and stairs. But, at the same time, it is necessary not to forget about the weight of products, which affects the design of the supporting walls and the foundation. It should also be remembered that when heated, the product begins to lose its rigidity due to its high resistance to fire.

The fence of the profile pipe 40x20 mm

From the previous paragraphs it became clear that the profile tubes are a fairly versatile product that can be used to create various kinds of structures. Today we will consider an option that is often found in everyday life, namely, a fence.

It will be relevant to the suburban area, if you want to give it more security and protect your life from prying eyes. You can build it without much difficulty with their own hands.

Simple profile pipes will be a good consumable, and their price will not hit hard on the budget. In addition, the article will help you make the installation yourself, which also contributes to significant savings.

Tip: during operation, take into account that the weight of 1 meter pipe 40x20x2 is less than 2 kg.

Prepare materials and tools:

- carrier pipe with a length of 1 m - width 50 mm;

- 6-8 pieces of a profile pipe about 300 mm long;

- two columns with loops and bolts for fixing - 60 mm wide;

- welding machine;

- Bulgarian or hacksaw;

- electric drill;

- Spanner or spanner wrench for bolts.

The following is a guideline for creating a fence:

- Mark the plot using threads and pegs.

- Every 1 m mark the place for installation of pipes.

Tip: installation depth should be about 300 mm.

- Weld two hinges to the pipe, which are required to secure the intake span. This can be a sheet with a thickness of 3 mm, and 2 chain links are common, when one end is welded to the pipe, and the other serves to fix the span. The last ring should be cut and diluted, then the ends will fall into the hole of the pipe. These are important nuances that need to be given due attention.

- Creation of the span is done with the help of a grinder or a hacksaw. You need to cut 7 pieces of pipe of 300 mm. But, not necessarily to maintain dimensions, it will be a plus decorative design.

Then cut a 900 mm long pipe for the base. Make a hole in it with a drill, in which the pipes will then be fixed. For vertical products, holes can be made using plasma welding or a conventional welding machine. Insert the pipes into them and connect them to the supporting structure.

- Attach the span to the hinge bars and fix with bolts, observing the level. In this case, the span can be raised above the ground, but if chains are used, it must touch the ground to withstand wind gusts. Remember that the weight of a 40x20x2 pipe with a length of 1 m does not exceed 2 kg.

Conclusion

This article has been considered profile steel pipes. They can be used in various sectors of activity, ranging from construction to finishing. More, we stopped at the most common pipe section of 40x20 mm, which is used for the manufacture of fences, pillars, gates and trellises. The video in this article will help you find additional information on this topic.