Profile pipe 50 50: characteristics and scope

Metal structures have always been actively used in construction, from elementary reinforcement to the construction of complex frames or trusses. At the same time there are such products that are most in demand in almost all areas of installation work. One of these elements is a 50x50 profile tube.

Purpose and characteristics

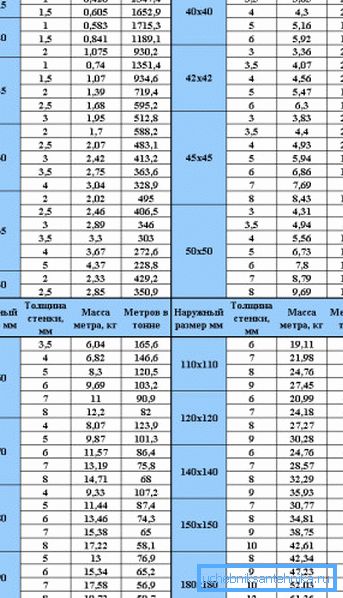

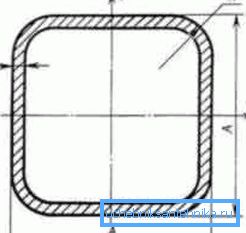

To begin with, it is necessary to say that this type of material is made of ordinary structural steel. However, its thickness may vary depending on the application, which is indicated by the number at the end of the marking. For example, if it costs 3, then just as many millimeters will be in the metal itself (read also the article Pipe 100x100x4: production, use, regulatory documents).

Sturdy construction

For the manufacture of supports or products, which will be heavy loads, it is necessary to use a material with thick walls. Therefore, professionals choose metal with a thickness of 4 or more.

However, it must be remembered that the larger this indicator, the higher the weight of the product.

- If the structure is overloaded with heavy elements, then its strength may not be useful, since it will collapse on its own.. Also large loads on the base can significantly shorten its life.

- First of all, it is worth knowing that the weight of 1 meter of a 50x50x4 shaped pipe is 5.78 kg.. Therefore, even with such a wall thickness, sagging may appear in a horizontal position. Given this, for each type of such products there are standards for the installation of supports or struts, not to mention stiffeners.

- It should be noted that the profile pipe 50x50x4 in a horizontal position fits mainly only on a specially prepared place. The fact is that to create strong beams, designers prefer to use an I-beam or channel bar.

- Considering all these features, the 50x50x5 shaped tube is used almost exclusively for the manufacture of columns or racks. This is due to the fact that the vertical load under its weight, it will carry a lot easier than in a horizontal location. At the same time there is another material for these tasks, the price of which is several times less.

Tip! When creating any structures made of metal, it is necessary to have a project with a drawing, in which all characteristics of the selected material and especially its weight must be taken into account.

Frameworks and trusses

The standard weight of a 50x50x3 profile pipe is 4.43 kg. This makes this type of material one of the most popular in the manufacture of various kinds of frames. In this case, experts recommend using it not only for vertical racks, but also in the manufacture of jumpers.

However, it is necessary to take into account that such a thickness of metal requires the presence of a special tool for cladding, since it is rather problematic to install a screw even with a pre-prepared hole with your own hands. It is better to always have a drill and a screwdriver on hand.

The main advantage of such products is that their thickness is perfect, both for working with self-tapping screws, and when using a welding machine. However, the installation manual strongly recommends selecting appropriate electrodes and try to avoid long joints.

Tip! It is important to know the exact weight in the running meter of the material, since many suppliers sell metal per kilogram. This will not mislead you or take advantage of this ignorance to gain additional benefits.

Lightweight construction

Based on the specification, the weight of the 50x50x2 profile pipe is 3.01 kg per running meter. That is why this material is used if necessary to facilitate the design. It is installed as jumpers, crossbars or small stiffeners.

Also, such products are used to create small structures in the form of greenhouses, greenhouses or kiosks. However, experts strongly recommend the use of products with greater strength in the corners of such buildings.

Special attention should be paid to the fact that the 50x50x2 shaped tube fits well into the category of thin-walled materials. Therefore, welding should be done very carefully so as not to burn the product.

Tip! It is best to use these types of materials as auxiliary products to facilitate installation or when organizing a bundle. However, some craftsmen cut them in half lengthwise to get two specific channels, which can be used as linings or in the manufacture of lintels on a window or door.

Conclusion

Having studied the video in this article, you can get acquainted in more detail with these types of metal products and their area of application. Also, thanks to the article that is presented above, it is necessary to conclude that when designing such structures, it is necessary to pay attention not only to strength, but also to the weight of the material used (see also the article Pipe 60 to 60 square profile: technical parameters and features of production ).