Profile pipe 80 to 80 - the main features of the manufacture

In the manufacture of any type of structures requires the erection of the frame, which will be responsible for rigidity. And if earlier it was necessary to use labor-intensive concrete work and to use not very comfortable reinforcement and round timber, then with the advent of profiled metal, everything became much simpler. The weight of the profile pipe 80 to 80 is quite small, but at the same time, reliability and durability are very, very large, which determined its popularity among developers.

The main advantages of this product group

To understand the reasons for the popularity of profiled products, first of all you should familiarize yourself with their advantages over other options:

| Application width | With the help of a proftrub, even non-standard architectural solutions can be realized, while the work is feasible even with your own hands, which cannot be said about other options. Of course, it is necessary to have some experience, but at the same time it is possible to master all the wisdom of the process without help. |

| Affordable price | If you compare materials in terms of price-quality factors, square designs look much more attractive than other options. You will not only simplify your workflow, but also be able to save significant funds. |

| Light weight | For example, the weight of 1 meter of a 80x80x3 profile pipe is only 7.13 kg, but at the same time its strength and resistance to deformation is much higher than that of round pipes of similar diameter. And if you compare with reinforced concrete, the difference in mass will be several times less |

| The convenience of use | The square shape greatly simplifies both transportation and handling, and installation. Due to the flat sides, the elements fit snugly to each other and to various surfaces in order to assemble a perfectly flat frame, no instructions are needed, everything is adjusted right on the spot |

Features of choosing one or another option

In order for the structures to be built to be reliable and durable, it is important to select elements with optimum strength indices. The most important characteristic testifying to the quality and deformation resistance is the mass of products.

Tip! Whichever option you choose, be sure to verify that the seller has documents certifying quality. Only products manufactured in accordance with the standards of GOST fully meet all the stated parameters.

The weight of the elements - the information necessary for each

Any profiled pipe has the following basic parameters:

- The length of each element, needless to be reminded, that a solid fragment is much stronger than a welded. Therefore, it is important to pre-calculate the necessary parameters so that you do not have to buy more material later.

- The size of the side, there are many options for both square and rectangular pipe products with different configurations. Naturally, the more parameters, the higher the mass.

- Wall thickness, without a doubt the main parameter that directly affects the reliability and load-carrying capacity of the structure. Naturally, the pipe 80 to 80 to 2 will be less durable than 80 to 80 to 3, it is worth proceeding from a specific situation. If the elements are not subjected to heavy loads, then less reliable options are sufficient, but if the impact on the structure is high, then the safety margin will not hurt in any case.

There are many options for calculating the mass per meter of products, we consider the most common ones:

- Using online calculators, the option is quite common and popular. The main thing is to choose the correct calculation system to avoid mistakes.

- The use of special mathematical formulas, this option is suitable if there is no computer at hand. But it is important to note that the actual result may differ from the calculated one due to the fact that the products differ in their actual parameters from the ideal geometric shapes.

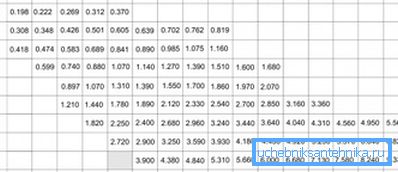

- Special tables with ready values are the easiest and most convenient way to calculate, since they already have all the ready data depending on the size and wall thickness. For example, if you need to know the weight of 1 meter of a profile pipe 80x80x4, you simply find the desired value. This simplifies the planning and calculation process.

Features of the production process

Note! Due to the fact that the products are mainly made from ordinary steel grades, it is very important to protect the surfaces from corrosion. The easiest option is to paint with special paints, which will not only protect the structure, but also improve its appearance.

Due to the configuration features, the process of making rectangular elements is more complicated than ordinary pipes, most often the following options are used:

- Hot-rolled pipes are made by deforming the blanks under the influence of high temperatures. This group of products has a very affordable price and a large range of thickness (most commonly used options are 80 by 80 by 4 or less).

- Cold-deformed pipes are more expensive, but their indicators of strength and resistance to deformation are much higher.

Conclusion

The use of hollow products with a square cross section allows you to quickly build reliable designs of a wide variety of configurations. The video in this article will tell some features of this group of materials in more detail and in detail.