Profile pipe: how to determine the quality of purchased

A shaped tube is a hollow metal inside, having a square, rectangular, or other cross-sectional configuration (with the exception of the circular one). This type of metal is widely used in modern construction for the installation of various complexity of structures.

In order to calculate various engineering parameters, it is necessary to know the exact weight of the running meter of the shaped tube. The instructions given in this material will tell in detail how to determine the various technical characteristics of these parts.

Method of determining the weight of profiled metal

Why do you need to know this indicator

The mass of the profile pipe is one of the characteristics by which you can determine the quality of the purchased goods. The running meter of metal-roll made according to GOST contains a certain amount of material, because the mass will fully comply with the value specified in this regulatory document (this statement is also true for used parts).

Otherwise, there is a violation of the technological process, which can lead to breakdowns of metal structures during their operation.

The second reason why it is necessary to determine how much a profiled pipe weighs is to calculate the engineering parameters of the finished structures.

Knowing the mass of parts, an experienced engineer or architect can calculate:

- loads that the used part will withstand when it is used in metal structures;

- loads that she herself exerts on other elements of a building or structure.

And vice versa, having an idea of how many meters of a shaped pipe are in a ton, it is possible to calculate the amount of material needed for construction.

Note! When calculating the final mass of metal structures, it is necessary to take into account the weight of additional parts, which include, for example, a crab-system for shaped pipes and other similar fittings.

Parameters affecting this indicator

The weight of the profile pipe, first of all, depends on how much metal and what brand it took to make it.

Therefore, the factors that affect the mass are:

- cross section configuration - square, rectangle and so on;

- side width - larger items will obviously weigh more for obvious reasons;

- part wall thickness - the more this parameter is, the harder the detail will be;

- material density - aluminum, as is known, is less dense than carbon steel, therefore the weight of 1 meter of a profile pipe from it will be less.

Calculate the weight of the finished product

For the manufacture of metal structures are most often used shaped rectangular sections. Depending on the size of the future building or structure, elements from 20 to 100 millimeters or more in width are used (see also the article Profile rectangular tube - dimensions and features).

Naturally, their weight can be found in the relevant building directories.

However, in practice this indicator is not always equal to the normative, since it is influenced by other factors arising in the production process:

- what type of tube rolling machine was used;

- what amount of impurities does the alloy used to make metal;

- what environmental conditions (temperature, humidity) were at the time of manufacture, and so on.

Note! A small deviation of the mass in one direction or another is not evidence of marriage. Also, the price of products does not depend on it.

GOST allows certain allowances for manufacturers. It is within this framework that the value you define should be.

So, in order to calculate the engineering indicators of the metal structures produced, regardless of the presence of accompanying and regulatory documents, it is necessary to calculate the necessary parameters with your own hands.

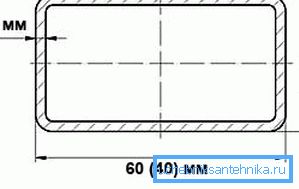

To do this, set the following parameters:

- the length of the acquired profile parts;

- wall thickness;

- width of the sides.

The values obtained are substituted into the following formula:

Mn = S * 2 * (A + B) * p, where:

- Mp is the mass per meter in kilograms;

- S - wall thickness in meters;

- A and B - width of the sides in meters;

- P is the density of the material from which the product is made (7.86 g / cc for steel).

Calculate the amount of material used

In the method described above, the weight of the product was determined by multiplying the volume of material used to make the pipe by its density.

Let us consider in more detail how to determine the value of the first factor in this formula.

There are several ways to do this:

- by determining the difference between the volume of the all-metal rod, which is a pipe and the volume of the internal (empty) space;

- by calculating the volume of a flat metal sheet from which the shaped part was subsequently made;

- by summing the volume of each facet of the product (this was done in the previous section).

Let's stop on the first method:

- We take a small piece of parts, the weight of which we need to determine.

- Measure the length of this piece.

- Determine the external dimensions and the dimensions of the internal space (in transverse projection).

- Then we multiply separately all values for the external and internal section.

- After that, you need to subtract the second value from the first value and eventually get the volume of the metal that you used to make the product you purchased.

- Finally, the resulting value of volume is substituted into the above formula.

The second way is as follows:

- The wall thickness is measured. This value is constant for the product, as the welded profile parts are made of sheet metal.

- Set the outer perimeter of the cross-section of the measured product.

- After that, you need to multiply the thickness, perimeter and length of the workpiece. Get the amount spent on the production of metal-roll material.

Note! The latter method is absolutely not suitable for determining the amount of material spent on the manufacture of profiled products by rolling. In this case, the statement that the wall thickness is the same throughout the product does not correspond to the truth and, therefore, the calculations will be incorrect.

Conclusion

Despite the fact that the weight of the profiled pipes is specified in the regulatory documents and accompanying documentation, it is necessary to additionally determine it yourself. Only then can we guarantee that the calculations of the mass and strength of the metal structures being erected will be correct (see also the article Steel Pipe - types and features).

You can learn more about this question from the video in this article.