Profile rectangular tube - dimensions and features

Profiled rectangular pipes are a special kind of tubular steel. The uniqueness of this product lies primarily in the non-standard cross-sectional shape. In this article, we take a closer look at the features of these products, their existing dimensions, as well as the scope.

Features of profile pipes

The unusual shape of the cross section of this product is primarily due to its purpose. Rectangular and square pipes are not used in pipelines, but used in frame metal structures. The fact is that the hollow tube has the same strength as a metal rod, and weighs 30-40 percent less.

Thus, the use of this material allows you to reduce the mass of metal structures and their cost, while their strength and cost will remain unchanged. However, it should be noted that these properties of the product have only if they are made according to GOST 8645 - 68.

In other words, shaped pipes have high strength only at certain section sizes. Even a small deviation from the norms can affect the overall strength of the steel structure or increase its mass.

In addition, design calculations of beams of steel structures for rigidity are usually based on standard dimensions, the values of which are indicated in the tables of the corresponding State Standards. Accordingly, if the sizes of the profiles do not meet the standards, the calculations will turn out to be incorrect.

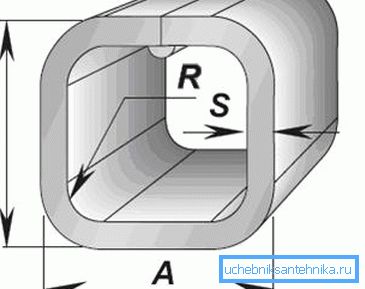

What sizes depend on

Under the size should be understood:

- The height of the walls of the product;

- Width;

- Thickness;

- Rounding radius.

All these parameters usually depend on the method of manufacturing products.

In industry at the moment there are three technological process of production of these products:

- Technology of cold deformation of a standard pipe;

- Hot deformation technology;

- Profile forming and subsequent welding of pipe joints.

The features of these technological processes affect:

- The method of alignment (calibration) of the profile section of products;

- Wall thickness;

- Rounding radius, etc.

Next, consider in more detail the features of products made by different production technology.

Application area

The scope of profiled pipes is very extensive.

Most often they are used:

- In construction - during the construction of various pavilions, sheds, stalls, etc.

- In the manufacture of furniture - shelves, racks, school furniture, etc.

- Automotive industry - in the manufacture of trailers and frames, etc.

- Agriculture - for greenhouse frameworks of pipes and other certain structures.

Of course, this material can be useful in the household, from it you can make arbors, fences, garden furniture, stairs and much more.

Merits

Among the advantages of this material are the following points:

- Strength;

- Low weight;

- Affordable price, thanks to the cavity material;

- Large assortment - thanks to this, you can pick up a product of the most suitable section size

- Plasticity - if necessary, the product can be bent, for example, by an arc.

- Easy installation due to low weight. Assembly instructions consist in the usual welding of parts.

Tip! It is possible to assemble metal structures not only by welding, but also on bolts. Such a compound is usually used for precast racks, scaffolding, all kinds of commercial equipment, etc.

Types of shaped tubes

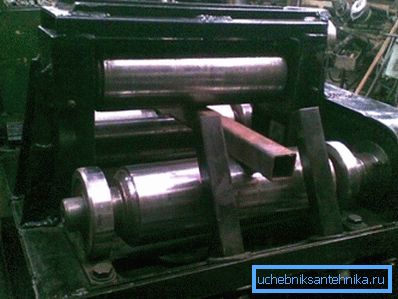

Hot rolled

Hot-rolled manufacturing process of these products is as follows:

- The billet in the form of a sleeve or a glass is heated to increase the plasticity.

- Then, the billet is rolled by molding rollers, as a result of which a pipe with a circular cross section is formed.

- Next, the semi-finished product is sent to a molding press, where it is transformed into a square, oval or rectangular product.

- The next step is cooling the billet and rolling on the sizing rolls.

- When the product is ready, it is heated to the temperature of the formation of the grain and gradually cooled in natural conditions. This operation allows you to remove the voltage in the crystal lattice.

The result is a product that meets the state standards, according to which the size of the pipe wall can not be less than 60 mm. Those. if the section has a rectangular shape, the height of the rectangle cannot be less than the specified value.

The range of a rectangular profile pipe in accordance with GOST 8639 - 82 (per square profiles) contains about two dozen sizes. The same size is determined by GOST 8645-68. Moreover, the dimensions of the section vary from 60x60 mm to 230x100 mm. True, the production of hot-rolled square tube allows a limit of 180x180 mm.

As for the other sizes, the profile rectangular pipes according to GOST 8639-82 may have:

| Minimum wall thickness | 4 mm |

| Maximum wall thickness | 14 mm |

| Minimum length | 4m |

| Maximum length | 12.5m |

Cold rolled

Manufacturing technology of cold-rolled profiled pipes consists of the following steps:

- The first is the preparation - the landing of a round hole in the washer.

- Then, the workpiece is rolled, as a result of which round tubes are formed.

- Next, the product is crimped in the press and roll mill.

- Then, as in the previous case, the calibration and heating (tempering) of the finished product are performed.

This technology allows to obtain smaller sizes of a rectangular profile pipe and its thinner walls. According to GOST, the minimum height of the section face is 10 mm. The maximum size of the cross section is limited to 120x120 mm.

This standard contains 17 standard sizes defined by state standard specification 8639-82, and also 16 standard sizes defined by state standard specification 8645-68. In general, it can be said that the choice of products of this type is justified if you need seamless pipes with thin walls.

Welded

The production process of welded rectangular profiles is as follows:

- First of all, dimensional sheet blanks are formed, which are cut off from a non-dimensional steel sheet.

- Next is the molding of the workpiece under the shape of the pipe section.

- The next step is welding of the seam by the method of induction melting and welding or in an inert gas environment.

- The final stage of production is the calibration of the semi-finished product by the method of cold deformation on the rollers.

The strength of these products practically does not differ from seamless ones, since the weld seam weakens rigidity by only 5-10 percent. But this technology, unlike all of the above, allows you to perform pipes with wall thickness from 1 mm to 5 mm. According to GOST 30245 2003 the minimum section size is 40x40 mm, and the maximum size is 300x300 mm.

Tip! When assembling structures from shaped pipes, for example, decorative elements, you can use all sorts of fittings - tips and other elements.

Here, perhaps, are all the main features of the material in question.

Conclusion

Profile pipes have a number of advantages, the main of which is good strength. Due to the above properties of these products and an extensive range of products, their area of application is very extensive.

The only products must comply with certain state standards, only in this case they have high strength characteristics. From the video in this article, you can get more information on this topic.