Profile square tube as a durable and reliable material in

Profile products thoroughly overshadow their predecessors (rental of a different configuration) in almost all areas of construction and industry. High strength characteristics of structures made from square and rectangular pipes allow building reliable, but at the same time, cheaper structures than using analogs of similar purpose.

Advantages of a square shaped tube

First of all, it is best to start familiarity with this product with the characteristics that the material possesses.

The great popularity of the profile pipe, besides the economic factor, was provided by the following factors:

- Products with a square or rectangular profile are much more effective in load-bearing structures subjected to plane bending.

Interesting! Resistance to loads and deformations at the rolled steel is higher by one third compared with the similar characteristic of a round pipe. However, in fact, it all depends on the quality and technology that was observed in production.

- The use of the profile pipe significantly reduces the construction time and facilitates the installation work as much as possible.

- Reducing the load on the foundation by reducing the mass of metal structures can significantly simplify and cheapen the stage of construction of the base.

- The rectangular and square shaped pipe according to GOST allows for the construction of the most incredible configurations. At the same time, it is not recommended to experiment on your own, as you may endanger yourself. To create unusual designs requires the skill and ability of the architect to make the right calculations.

- And finally, rolled sections are by far the easiest to process, as for special compositions for:

- Providing increased heat resistance.

- Anticorrosion protection.

Note! Some manufacturers produce products already fully prepared for installation, but most are limited only by the release of products from quality material. Therefore, purchasing products, check with vendors, suppliers, the need for preparation and pipes for installation.

All of the above makes square and rectangular pipes very attractive not only for industrial facilities, but also for private construction carried out on their own.

The manufacture and use of profile pipes

Depending on the method of manufacturing, the profile tubes are distinguished by:

- Welded.

- Seamless.

Hot-rolled sheet welded pipes

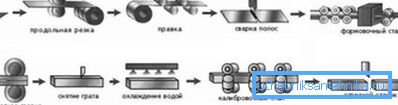

For the manufacture of welded shaped pipes at the mills, hot-rolled steel strip is used as raw material.

In the production of such products of small and medium size steel is used:

- 1 sp / ps

- 2 sp / ps

- Less often 3 sp / ps.

This relatively inexpensive raw material makes a square and rectangular tube made of it widely used in the construction of various structures, mostly external, such as:

- Frameworks from pipes of different types of visors.

- Metal doors.

- Pavilions and canopies.

- Fences and railings.

- Constructions for public transport stops.

- Small architectural forms.

The use of large-size rolled products for the construction of load-bearing structures has led to its manufacture from steels 3-5 categories, which are characterized by normalized:

- Chemical composition.

- Mechanical characteristics.

Cold rolled profile tubes

The production of rectangular and square pipes is also carried out from cold-rolled steel tape with the formation of a steel profile on a special tube mill with high-precision rolling. This ensures electric cold-rolled products with high definition of geometry and trimming.

Cold-rolled welded profile products are used in the manufacture of furniture and interior items.

Of these products are made:

- School Desks Frameworks.

- Support and frames transforming sofas.

- Lamella bed bases.

- Elements of outdoor advertising.

- Racks for trading floors and warehouses.

The price of such products is quite high, so they are only involved where their technical characteristics are necessary:

- High quality surface.

- Precise geometry.

- Flexibility when bending.

A square tube made of metal with the use of cold-rolled steel 08ps, 1-2 ps is usually produced with a small cross-section and a wall thickness of 0.8 to 1.5 mm. Often these profiles are covered with protection from special anti-corrosion compounds.

Seamless square tubes

In the field of construction, where particularly high demands are placed on the reliability and safety of operation of structures, seamless square and rectangular pipes are used.

Note! Of course, in the area of the weld, the welded profiles have lowered strength indices by 10-15%, and this is subject to a uniform load distribution. Therefore, when installing it is very important to observe all the features of this product and arrange it correctly.

The cost of a seamless profile product due to the particular complexity of the production process is high and, therefore, the area of its application is not extensive and specific. But it is in these areas that products do their job better than others.

The design of any kind of structures is performed using technical documentation, which for metal products of this type is called:

- Range on profile square pipes in accordance with GOST 8645-68. This standard covers seamless (hot-rolled and cold-drawn), as well as electric-welded rectangular pipes. The sizes of products from this range are in the range from 10x15x1 mm (width; cross-section length; wall thickness) to 150x180x12 mm. According to GOST 13663-86, the following technical requirements are imposed on these profile pipes (depending on the purpose):

- Group A with the obligatory standardization of mechanical properties, production of steel of steel, grade 2-4 kp / ps.

- Groups B with obligatory rationing of mechanical properties are made of steel of grade 2-4 kp / ps, possibly 10-35 and 08kp.

The grade for a profile pipe is a detailed instruction containing the following information about each specific product:

- Section dimensions (length, width, wall thickness, rounding radius).

- Cross-sectional area.

- Mass of one running meter of pipe.

- Moment of inertia.

- Moment of resistance, etc.

Conclusion

In modern construction it is hardly possible to find an object on which the above described products are not used. They can be used not to create the foundation, but, for example, to reinforce any structural elements, as additional supports. In any case, we hope that the above information will be useful to you and helped to find answers to the questions posed.

In the presented video in this article you will find additional information on this topic.