Pvc sewer pipes: how to choose the appropriate material for

The time is long gone when the main material for the manufacture of drainage systems was cast iron. Now his place is firmly occupied by plastic, or rather one of its types - polyvinyl chloride. The sewer pipe of NPVH (PVC) possesses a set of advantages which allowed it to take the leading positions in this sphere.

What is the secret of such popularity?

Product Features

Performance parameters

Consider the main technical characteristics of PVC sewer pipes, emitting them from other similar materials.

| Parameter | Description |

| Long service life | There is no rust on the plastic, because such pipes can serve for quite a long time - the period of operation, guaranteed by manufacturers, is more than 50 years. |

| Low weight | These products are easy to transport and install without the use of special engineering equipment. In addition, in the arrangement of sewage can be used lightweight fasteners, which has a positive effect on the cost of the entire system. |

| Ease of installation | All work on the design of the sewer system can be done by hand. You do not need special equipment or glue. It is enough to clean the ends of dirt and dust, lubricate for reliability with liquid soap or silicone (optional) and connect the parts. |

| Low price | Compared to cast iron or steel sewer systems, the cost of material and work will be much lower. |

Pipe classification

Before you choose the size of PVC sewer pipes, you should decide on other parameters, which also play an important role.

At the place of installation, these products are divided into several types:

- Outdoor Used to create trunk drain pipelines, storm sewers and other similar hydraulic structures. The diameter of PVC sewer pipes used in this case is 110 mm or more. In their production, a more durable plastic is used that can withstand mechanical stress.

- Internal. Suitable for installation of the drainage system in residential and office buildings. Here such PVC sewer pipes are common: 75 mm, 63 mm, 50 mm.

Another classification criterion is the parameters of the working environment inside the pipeline.

There are such varieties:

- Free-flow. They are intended for transportation of fluid, the rate of which natural flow (without using special equipment) is no more than 8m / s. The pressure inside the pipeline must not exceed atmospheric.

- Pressure head. Increased pressure may build up inside. Depending on the cross section and design features, the PVC pipe walls can withstand pressure reaching and exceeding 10 atmospheres.

- Corrugated. The feature of this pipe is flexibility. With its help, you can create pipelines of complex configuration without the use of shaped parts, which prevents the formation of traffic jams and blockages in the sewage system.

Note! The bulk of PVC products is intended for the transportation of non-aggressive and slightly aggressive liquids. If you need a pipeline for oil, fuel and other similar substances, you should purchase special parts made using more sophisticated technology.

Tips for purchasing material

Choosing pipes for the manufacture of sewage systems, pay attention to the following features:

- internal and external size;

- the length of each individual section;

- strength of plastic used;

- internal environment parameters;

- special characteristics (for example, there are pipes made of plastic, which is not subject to burning and melting - they are used for laying electrical cables).

PVC sewer pipes are manufactured according to GOST.

Therefore, regardless of the name of the manufacturer, they all correspond to the following parameters:

- have the marking approved by regulatory documents;

- undergo various tests necessary to analyze their technical characteristics;

- shipped in standard protective packaging.

Tip! The final certificate to ensure that the purchased material complies with GOST. Require a copy of such a document for review before purchasing. Only this way you will be sure that you will receive a quality product.

Assembly process

Compound

Having dealt with the order of selection and purchase of materials, it's time to go to the question of how to connect PVC sewer pipes.

The instruction describing the process is quite simple:

- Make sure that the cut of the pipe is trimmed and the chamfer is removed.

- Check for rubber o-ring in the socket.

- If necessary, clean all elements of dust and dirt.

- Apply liquid soap or silicone grease to the smooth end of the pipe or fitting.

Lubricant:

- will provide easy installation of PVC sewer pipes;

- reduce the coefficient of friction between the parts and prevent deformation due to high temperature, and also eliminate the possibility of sticking and warping of the drain system;

- will keep tightness of a rubber sealant for a long time.

Note! Lubricate the inner surface of the socket is optional.

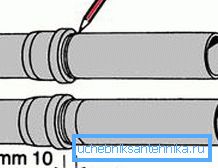

- The parts are connected to each other, after which a risk is marked on the element with a smooth end, marking the location of the socket.

- Then move the part back 10 mm. Measure it will help markup. This gap can compensate for the linear expansion of the pipe as a result of the high temperature of the fluid flowing through it.

- If a molded part is mounted, its smooth end can be left in as far as possible.

Cutting

Sometimes it is necessary to cut the pipe. To do this, you can use a regular hacksaw for metal or a special device that forms a chamfer at the end of the cut section.

If you do not have it, do not get upset. You can give the desired shape with the help of a file.

The angle should be about 150 degrees. This will protect the O-ring from damage.

Remember that shortening shaped parts is prohibited.

Conclusion

The right choice of material for the installation of a sewer system is a guarantee of its long and trouble-free operation. For more information about the materials used, you can learn from the video in this article (see also the article Properly equipped sewage in the bathroom).