Rectangular tubes: technical specifications and gauge

Parts that have an internal cavity and a cross-section in the form of a square or rectangle are called shaped tubes. They are often used to make various designs with their own hands. The material below will allow you to sort out the whole variety of existing parts and select products that best fit your needs.

Features of rectangular pipes

Manufacturing process

Profile metal pipes can be manufactured in two ways:

- By rolling round products. To do this, take the part of the desired diameter and is processed using a rolling mill. Depending on the technology used, the size and material of the parts, the following is applied:

- hot rolling - a round pipe is processed after it is heated to a certain temperature;

- cold working - changing the shape of the pipe occurs without prior heat treatment

- By pressing. In this case, the pipe is formed from a flat billet, followed by welding a longitudinal seam.

The advantages of profiled products

The material has many advantages over circular parts:

- Even with significant physical exertion, the product is practically not subject to deformation.

- Finished metal structures from square and rectangular pipes are very durable. In addition, they are distinguished by a lower price, since the hollow form reduces the amount of metal used (as opposed to fittings and square rods). (See also the article Hot-Rolled Pipe: Features.)

- Profile products have less weight compared to full-bodied parts.

- Correctly selected rectangular or square detail can be used for the manufacture of structures of very complex shape. It bends well without deformation and is easier to weld with other parts.

- The product has a long service life (especially those made of non-ferrous metals).

The size of the product is determined based on the tasks for which it is intended. Some types of profile pipes are made from special steel grades that can withstand aggressive environmental conditions. Such parts are used for the installation of drilling rigs in the open sea and areas with very low air temperature.

Note! The use of metal structures from profiled parts can significantly reduce the amount of concrete used and as a result, reduce the weight of the structure. Thanks to this, you can quickly build high-rise buildings and build a less massive foundation for them.

Kinds of pipes of rectangular section

Regulatory options

The range of rectangular pipes according to GOST is quite diverse. They are classified according to various criteria, which allows you to more consciously approach the choice of the variety you need.

General GOST for profiled pipes has the number 13663-86.

According to this document, there are several technologies that produce products:

- hot rolled seamless;

- cold formed seamless;

- shaped electric;

- cold-deformed electric products.

Separately, the following standards governing the technical characteristics of parts are distinguished:

- rectangular products - according to GOST 8645-68;

- square - according to GOST 8639-82.

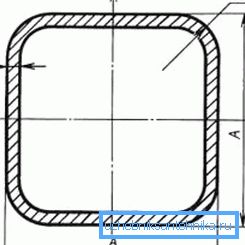

The above instructions stipulate that manufactured models should have the following parameters:

- the width of the side of the square part is from 10 to 180 mm (from 32 to 60), and the wall thickness is from 1 to 14 mm (from 4 to 6);

- dimensions of a rectangular product should be 15x10 mm (28x25), and the wall thickness from 1 to 12 mm.

The length of the products depends on the method of their production. In more detail, these parameters are listed in the table.

| Type of | Unmeasured | Measured | Multiples |

| Hot rolled seamless | from 4 to 12.5 meters | from 4 to 12.5 meters | from 4 to 12.5 meters |

| Cold formed seamless | from 1.5 to 9 meters | from 4.5 to 11 meters | from 1.5 to 11 meters |

| Electrowelded | from 1.5 to 9 meters | from 5 to 9 meters |

Scope of application

The main advantages of the products are obvious:

- high bending strength;

- small weight;

- good resistance to various loads.

Due to this, profile parts are widely distributed in many industries. Products come in various sizes, they can be given almost any shape. Most of the complex metal structures are made of square or rectangular pipes.

The main scope of the material in question:

- construction of supporting structures with low weight;

- construction of sites for various functional purposes;

- installation of metal supports and transverse stiffness bars;

- the creation of boxes for laying cables and so on.

From the products in question are very light and durable frames. Because this material is widely distributed in the automotive industry, it is used for the manufacture of advertising and other similar structures.

Products made of core elements contain 30-40% less metal, which allows the use of less massive foundations, further reducing the estimated cost of construction.

To connect parts of pipelines are usually used:

- electric welding;

- screw plug connection.

Other features

Thanks to the stiffening ribs formed by the four corners of a rectangle or square, the pipe is very durable because it is widely used in the construction of buildings. Its low weight and internal cavity practically does not affect the rigidity of the curved section.

This is due to the fact that when bent, the main load falls on the edges. At the same time, due to the lack of a core, the latter is not subject to destruction and severe deformation. The main task is to choose the correct section of the part.

Another important factor is cost effectiveness. Due to the fact that the cost of profiled pipes is about a quarter lower than that of conventional products of similar diameter, it is possible to significantly save on the acquisition of materials for construction. Moreover, they are easier to transport, store and mount on smooth surfaces.

The connection of these parts occurs with the help of automatic and semi-automatic welding machines. This seam has increased strength, because it is square and rectangular pipes that are used to create complex and massive metal structures.

Tip! When purchasing pipes for construction, be sure to check its quality. The weight of the pipe must exactly match the parameters specified in GOST.

Conclusion

Rectangular and square pipes are an excellent material that is widely used in the construction industry. Using them, you can not only design solid and reliable buildings, but also significantly reduce the estimated cost of work. More details about this can be found in the video in this article.