Reinforced concrete pipes - features and application

Despite the fact that the market offers a large selection of metal and plastic pipes, reinforced concrete products have not lost their relevance. This is evidenced by the great demand, both for reinforced concrete pipes and new products.

Further we will get acquainted with their features, types and scope of application.

Features of reinforced concrete pipes

Merits

First of all it should be said that there are two technologies for the manufacture of reinforced concrete pipes:

- By centrifugal casting technology;

- By vibropressing.

Both of these options allow to achieve reliability and high quality products.

In particular, the following advantages of reinforced concrete pipes can be distinguished:

- High strength.

- Ability to withstand severe mechanical stress.

- Frost resistance, so that the pipeline of reinforced concrete can be operated in a harsh climate.

- Resistance to sudden temperature changes.

- The installation of the pipeline is simplified by the bell-shaped and faltsevoy structure. However, for the installation of large diameter pipes it is necessary to use lifting equipment.

- Resistance to corrosion and decay, so that the concrete pipeline in many cases more preferable than metal.

- Durability - the service life can reach 50 years.

- Affordable price.

Thus, concrete is the best material for pipelines, the operation of which is associated with possible high external loads, as it is more durable than plastic. Therefore, such pipes are most often used for industrial communications, as well as as structural bearing elements.

disadvantages

Of course, concrete pipes, like any other materials, are not without some drawbacks, among which are:

- Big weight - it complicates their transportation and installation.

- The inner surface of the walls has a rough surface, which increases the resistance to flow. However, in some cases, to eliminate this drawback, the surface is covered with special coatings.

- Instability to aggressive environment, so the reinforced concrete pipeline can not be used to transport chemicals.

Types and design features

Connection methods

Concrete goods of a pipe first of all differ as connection.

They are:

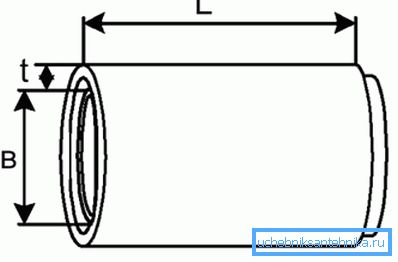

- Flange - in a form are similar to plastic and pig-iron sewer products. Sealing of the joints is carried out using special seals. It must be said that these pipes are the easiest to install, therefore, when constructing pipelines, they are most often used.

- Faltsevye - they are distinguished by the fact that along the edges they have selected quarters that allow individual elements to join. Instructions for their installation involves sealing the joints of the usual cement-sand mortar.

The main advantage of such products is that they have the same outer diameter throughout the length. However, if a reinforced concrete pipe is laid in a ditch, then it does not really matter.

It should be noted that both of these types of pipes are available in both pressure and non-pressure versions.

Marking

It is not easy for a beginner to choose with his own hands reinforced concrete pipes for various tasks, as they are of different types. To help in this matter will help the next marking, which is a combination of letters and numbers.

It is deciphered as follows:

- The first group of numbers - denotes the internal diameter in centimeters.

- The second combination - indicates the length of the pipe (in decimeters).

- The last digit indicates the class of the bearing capacity of the product. From this value depends on the allowable depth, which is allowed to bookmark highway.

Note! Pressure pipes are manufactured in four basic versions of the working pressure, which can be from 5 to 20 atmospheres. These products can be used to transport any non-corrosive liquids.

The letter abbreviation allows to obtain the following information about the product:

- Pressure pipes are marked with the abbreviation TH.

- Non-pressure bell-shaped pipes are marked with abbreviations - T, TBP, TP, TS, etc. Marking in this case speaks about the features of the docking station, for example, a socket with a rim, a socket with a sole, etc.

- Pipes with a folded joint are similarly labeled - TF, TBFP, DFP, TE, TH, etc.

Application area

Pipes from reinforced concrete successfully used in various fields of civil and industrial construction.

Most often, this material is found in such structures:

- Sewers for removal of industrial and domestic wastewater. Large diameter products are widely used when laying trunk collectors.

- Sewer storm nets.

- Highways for transportation of liquids (not aggressive in composition).

- Drainage systems through road embankments.

Note! Recently, reinforced concrete chimneys, which have a number of advantages over steel analogues, have become widespread.

In addition, as mentioned above, rectangular and round pipes are often used as structural elements, for example, in the construction of foundations, as supports for fences, etc.

Conclusion

Reinforced concrete pipes have become the traditional material in the construction of a number of civil and industrial structures. This is due primarily to their strength and many other characteristics. However, due to some shortcomings, like any other material, they cannot be called universal.

From the video in this article, you can get more information on this topic.