Reinforced polypropylene pipes for heating: the choice and

Polypropylene reinforced pipe for heating (type PN 25) has found wide application in the construction of residential and public buildings.

Features of products from polypropylene

The urgency of using these products is not accidental, since they have such advantages as:

- increased throughput;

- long operational resource;

- ease of installation work with your own hands;

- resistance to mechanical deformations;

- less likely to cause blockages;

- more affordable price compared to the cost of metal counterparts.

In this article we will consider the main characteristics of these polymeric products, as well as describe the features of their selection and operation.

Main varieties

In the domestic market, polypropylene reinforced pipes for heating have appeared relatively recently, but have already gained sufficient distribution.

These polymeric products are available in the following varieties:

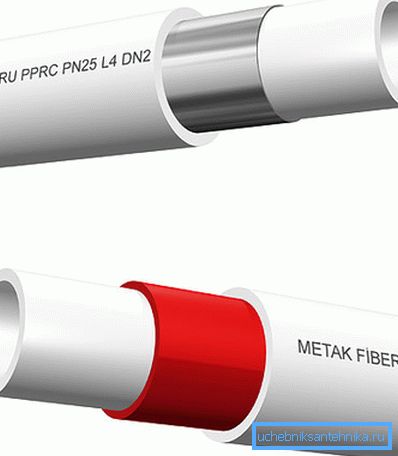

- Three-layer modifications consist of the outer and inner layers of polypropylene, while the interlayer between them is made of aluminum foil or fiberglass.

- The five-layer modifications also consist of an inner and outer polypropylene layer and of a fiberglass or foil layer. But, in addition to the listed interlayers, two layers of hot melt adhesive were used in such pipes, which provides products with higher strength with a slight increase in wall thickness.

Important: Despite the fact that both of these modifications are equally suitable for transporting coolant, it is the five-layer pipe that can be used in systems where heated water circulates under high pressure.

In accordance with the type of reinforcement, the following types of polypropylene pipes are distinguished:

- Modifications reinforced with an aluminum continuous sheet (marking PPR-AL-PPR), in which aluminum foil is applied over the entire outer side of the product. When mounting, the aluminum layer at the ends of the pipes is cut to the distance required for the installation of connecting fittings.

Important: Stripping aluminum foil at the ends of the pipes is carried out using a special device, the shaver.

- Modifications in which the reinforcement with an aluminum sheet is uneven and is enhanced either towards the ends or towards the middle of the product. Such pipes before installing the fittings are not cleaned.

- Fiberglass reinforced versions (labeled PPR-FB-PPR) are three-layered pipes where the inner and outer surfaces are made of polypropylene.

- Modifications reinforced with composite materials (a mixture of polypropylene and fiberglass) are also represented by pipes, where the internal and external surfaces are made of polypropylene.

Important: Some manufacturers produce pipes, where the reinforcement is made of aluminum perforated sheet. Acquisition of such products for use in autonomous heating systems is not recommended due to the increased oxygen permeability of the product.

Due to the presence of perforation, it is likely that oxygen will accumulate in the heating system, which will adversely affect the operation of the heating equipment.

Manufacturing features

The instruction for the industrial production of reinforced polypropylene pipes is based on the dual coextrusion method. During the production process, special equipment is used - an extruder.

Through a special nozzle of the aggregate, the polymer mixture is squeezed out by two layers, which form the inner and outer sheath. Despite the seeming simplicity of the production process, the use of an extruder is high-tech and requires a qualified approach to carrying out these works.

The production of heating pipes is carried out taking into account a wide range of sizes, including the length of the product and the internal diameter of the cross section. That is why the choice of a product allows you to purchase everything you need for heating in most country houses.

Polypropylene pipes for heating reinforced with fiberglass or aluminum are complemented by special connecting elements - fittings.

Currently, specialized brands produce a wide range of fittings that allow to perform installation work without the use of metal parts.

A separate category of fittings is designed to connect polypropylene pipes to a metal pipeline. Such connecting elements are made of polymeric materials and at the same time are equipped with brass or silumin inserts, which, in contact with steel reinforcement, do not provoke a corrosive process.

A wide range of polypropylene products is made taking into account various color designs. For example, you can purchase pipes and fittings in gray, white, black, and green.

One or another color does not guarantee any advantages. Therefore, when choosing a color you need to be guided by how the pipes fit into the interior.

Important: According to experts, polypropylene products, painted black, are characterized by increased resistance to ultraviolet radiation.

Main characteristics

Pipes reinforced polypropylene for heating characteristics of which are in many ways unique, are the most popular material from domestic plumbers.

Such pipes are installed in various types of cabling, and this is not surprising, since PN 25 products are characterized by the following properties:

- Operating life of at least 50 years in the case of a properly performed installation and at a normal pressure in the system (no more than 10 Bar with a maximum temperature of up to +95 ° C). The problem of overpressure in heating systems today is almost never encountered, as boilers with the ability to adjust this parameter are commonly used. If the pressure above the specified parameters can be purchased metal pipes, designed for more pressure.

- Ideally smooth internal surface resistant to most applied coolants. For example, if the entire metal water supply is covered by micro-relief from within, due to the influence of the coolant, the PP-pipes remain perfectly smooth throughout the entire life cycle.

- The possibility of mounting using easy-to-use equipment, the price of which is low. If the formation of a metal pipe requires equipment for cutting threads and bending individual elements at the right angle, then in the case of plastic pipes, everything is an order of magnitude simpler. As a result, the installation of polypropylene can be performed in any conditions.

After we have decided on the main characteristics of reinforced polymer pipes, we will look at the instructions for assembling heating systems using these materials.

Features of the installation

Important: Welding multi-layer polypropylene pipes using conventional polymer fittings requires a special approach. The fact is that the bare ends on products with PPR-AL-PPR markings in contact with the pressure of hot water are eroded as a result of cavitation processes. As a result, the aluminum layer gradually stratified, which leads to the destruction of the soldering.

How to avoid destruction of the aluminum layer when welding pipes and fittings using a special soldering iron?

There are several recommendations, following which you will avoid the negative effects of contact of the metal and the coolant:

- When starting welding, make sure that the end face is even. This will eliminate the formation of gaps between the edge of the section and the internal cavity of the fitting.

- Carefully check the inner surface of the pipe at a distance of 1 cm from the cut. There should be no scratches, abrasions and scuffing throughout this distance.

- Welding the pipe and fitting, we combine both parts with maximum force up to the stop. In this case, the cutting line will be buried in the internal cavity of the fitting and melted, which will exclude the contact of aluminum with water.

Important: All the above recommendations should be observed when working with composite pipes with composite reinforcement. As a result, the result of the installation will be especially high quality.

Conclusion

So, we have learned what a polypropylene pipe with a reinforcing layer is. In addition, we looked at how these products can be applied for their intended purpose so that they can be operated efficiently and as long as possible. You will find more useful information by watching the video in this article.