Rollers for profile pipe

The only tool that can change the shape of a shaped pipe is the rolls. And since bent metal products are often used in construction, this tool is simply indispensable. Rollers for the profile pipe are of different types, including they can be made independently.

Types of rolls

Structurally, this tool for the formation of shaped tubes of arcuate shape can be divided into types, according to the source of applied force.

Electric rollers are the most productive, they are characterized by the largest number of bent products produced per unit of time compared to other types. Productivity increases due to the presence of a working electric motor, with the help of which the formation of a new pipe shape occurs fairly quickly.

The main structural elements of electric pipe bender:

- the basis which is a metal bed;

- from 3 to 5 rollers that rotate by means of an electric motor;

- power plant in the form of an electric motor;

- deforming clamps.

Manual rollers for bending the profile pipe are considered practical portable tool. Due to their relatively small size and the absence of an electric drive, they are installed in any suitable place, even where work space is limited. The design of the hand rollers for bending the profile pipe is similar to the electric one, with the only difference that they do not have an electric drive, and the feed rollers are interconnected by transmission to a chain, which with the help of clamps deforms the pipe.

Manual pipe benders are characterized by design flaws. Despite the fact that such rollers are very convenient to perform a small amount of work, they need to use considerable physical force. It is not so easy to bend a metal pipe with a transmitting force on clamps and chain transfer to one person. If the worker is not a sufficiently physically developed person, or fatigue from frequent repetition of operations has accumulated, such a tool in production will be unproductive. Therefore, such a hand tool is useful only in the manufacture of small batches of bent products.

Hydraulic rollers are considered the most powerful technique in comparison with the above described analogs of bending tools. A hydraulic press in combination with a clamp transmits such a powerful force to the profile pipe that it bends like a reed. Such a unit can rightly be called a "super heavyweight." The bending force in a particular case is built up by the hydraulic complex, which is easily maintained and controlled. If, in addition to the existing equipment, to add an electric motor acting on the feed rollers, the efficiency of the unit increases significantly, the performance and capacity capabilities will be combined.

Tip! Such a device can be further improved. If the feed drum is replaced with a profiled shaft, then in one run it will be possible to bend several profiled pipes at once. Due to the properties of the hydraulic press and electric drive, such a machine is able to process any number of products.

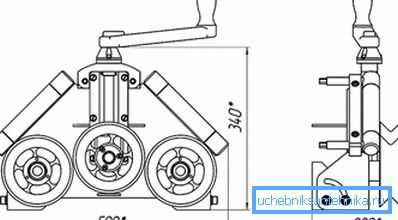

Unfortunately, hydraulic rollers weigh a lot. This disadvantage is manifested in the fact that if you install it somewhere, then this place will remain for the unit as a worker for a long time - it will be very difficult to move it from its place. In order to understand the device of the tool and, in principle, the deformation of the profile pipe, you can see the below drawings of the rollers with the dimensions applied.

The principle of operation of the rollers

To bend the profile tube on the rollers, no special knowledge and skills are needed. An employee needs to perform only a few operations:

- The pipe falls on two feed rollers.

- With a certain force, the pipe is pressed against one bending roller to choose from.

- The gear is engaged.

As a result of the passage of the profiled pipe through the working area, it is bent at a planned angle. In case of insufficient degree of deformation, the workpiece is once again passed through the working elements of the tool, while it is necessary to control the clamping force.

Making homemade rollers

Today, self-made rolls for a profile pipe are often found in everyday life. For a bed the wide channel is applied. The bending mechanism can be made from a U-shaped design using a hydraulic jack or by welding with a wrench top plate.

- If you use a jack, it should be located under the bed, and the power to rush from above to the feed rollers.

- In another case, the pipe is bent threaded clamp. The stud is screwed into the nut, and the heel is welded to the end of the desired shape.

When feeding pipe, you can use a regular bicycle chain. Asterisks are welded onto the drive and driven shafts and the chain is tensioned. The handle is attached to the drive shaft.

Tip! In terms of hardness, the feed rollers must exceed the profile tube, so they are hardened.

Video

We suggest you look at the homemade pipe bender: