Seamless pipe: features of production and use

Despite the active introduction of modern plastic pipes to create all sorts of communications, steel counterparts are in no hurry to leave their positions. Due to the technical characteristics with which they are endowed, durable products are indispensable in some cases, in particular, their priority in arranging water supply systems at industrial facilities remains.

Classification and production methods of steel pipes

The pipeline is a very important element of any construction, which is why it is worth paying special attention to all the element of which it is composed. Further detailed information will be presented on seamless pipes, products that have no analogues in the construction market, many ordinary citizens may not even be aware of the existence of the latter.

Manufacturing

According to the method of production, an extensive range of steel pipes is conventionally divided into two groups:

- Seamless (cold rolled, warm or hot-rolled).

- Electrowelded (with a straight or spiral stitch).

Note! The first group is characterized by higher strength and performance characteristics, as well as a complicated production process. Among electric welded products, spiral-seam pipes are leading in terms of these indicators.

Wall thickness

Regardless of the method of manufacture, and in accordance with the diameter and purpose of steel pipes are produced and classified by wall thickness:

- Thin-walled. These are steel products with a diameter of up to 20 mm (wall thickness is equal to or less than 1.5 mm).

- Particularly thin-walled. These include pipes with a corresponding parameter of less than 0.5 mm.

- Thick-walled (thickness over 2 mm).

- Particularly thick-walled.

For seamless steel pipes, we use another recognition parameter - the ratio of the outer diameter and wall thickness:

- A seamless thick-walled pipe according to GOST has a ratio of these values from 6 to 12.5.

- The ratio of less than 6 units characterizes especially thick-walled pipes.

- For thin-walled, with a minimum weight per meter, this ratio is 12.5-40.

Normative base

To determine the class of pipes for the purpose of planning or designing specific objects there is a range. This is a technical standard that reflects all the basic parameters in this case of pipes, up to the grade of steel used in the manufacture of a particular product.

For example, the assortment on seamless pipes in accordance with GOST 8732 78 covers the production of continuous pipe-rolling without a seam (longitudinal) made by hot deformation from steel with different chemical composition.

Seamless pipe according to GOST 8732 78 may have the following geometrical parameters:

- Diameter ranging from 20 to 550 mm.

- Wall thickness from 2 to 45 mm.

- Length:

- Non-dimensional (4000-12500 mm).

- Measured in fixed sizes.

- Multiple dimensional.

The price of a seamless pipe depends on the production method, as well as on the quality and chemical composition of the raw material. Also, to the cost of products, you can add transportation to areas where such products are not produced, and this is in some cases about 20-30% surcharge.

GOST for seamless pipes is strictly regulated by the classiness of the steel from which they are made for a particular application.

In industries with increased requirements for performance characteristics is used:

- The pipe 12kh18n10t made of stainless steel. Such a product can work:

- Under pressure.

- At temperatures in a wide range from - 196 to +600 degrees.

- With aggressive media solutions (at temperatures up to +350 degrees):

- Acids (nitric, phosphoric, acetic).

- Alkalis

- Soleil

- Hot dip galvanized.

- Electro galvanic.

Galvanized seamless water and gas pipes with high corrosion resistance and resistance to deposits on the inner surface are mainly used to create internal systems:

- Water supply:

- Cold

- Hot.

- Heating.

- Gas supply.

Seamless hydraulic pipe, made according to DIN 2391 by cold and warm deformation, is used:

- When creating a special technique (road, agricultural and construction, etc.).

- When creating pneumatic and hydraulic shop lines.

Note! In general, equipment made from the above products, has high strength and long service life, of course, subject to the maximum permissible loads.

Hot deformation

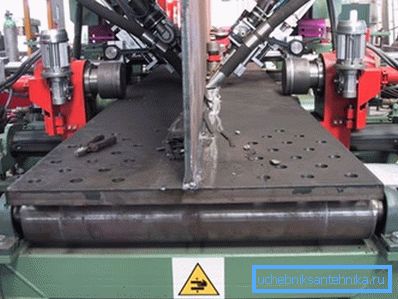

A few words about how to make seamless pipes. The production technology of a seamless pipe involves the use of a monolithic piece of cylindrical shape, called a rod.

The step-by-step instruction of this process is as follows:

- First, the billet is heated to a temperature above the crystallization threshold of the alloy by 50-60 degrees. The metal becomes plastic, but not yet melted (acquires the ability to change shape).

- On a special piercing press, the billet turns into a hollow cylinder that looks like a pipe with very thick walls.

- Next, perform the shaping of a pipe of a given shape with a certain wall thickness by hot deformation on various equipment (mills for various purposes):

- Pilgrim rolling.

- Automatic.

- Raskatochnom longitudinal helical rolling.

- Rail.

- Continuous.

- The formed pipe undergoes very rapid cooling and is refined (calibrated) on the rollers.

- At the end of the process, cutting into individual pieces of standard length is performed.

Note! All these processes are required to obtain a quality product, manufacturers that do not comply with the manufacturing technology, offer low quality pipes.

Cold forming

The production of seamless pipes by the cold method has two differences with the above described hot-forming:

- Cooling is carried out directly after the workpiece firmware. Pre-hire is carried out in a cold state.

- Before hitting the rollers, the liner is annealed for final formation, that is, it is heated to the state of recrystallization of the alloy. (See also the article Pipe rolling: features.)

Assembly work

There are no particular differences in the work with seamless and electric-welded pipes, however (especially when doing the work with your own hands), some nuances should be taken into account:

- The difficulty, and sometimes the impossibility of cutting threads on thin-walled pipes, limits the use of threaded connections on them.

- Thick-walled products before welding must be prepared-chamfer on the joint edge. This will help to perform high-quality welded joint, if this is not done, you can not boil the entire thickness of the metal, which will significantly reduce the reliability of the pipeline at the junction.

- It is better to connect thin-walled pipes with the help of gas welding, while observing the maximum allowable working temperature. (See also the article Butt-Weld Pipe: Features.)

Conclusion

I would like to once again highlight the main advantage of the materials described by us - strength along the entire length of the product. What can be said about the structures produced by welding and consisting of several elements.

Everything that was described earlier will help you make the right choice in favor of this or that material. In the presented video in this article you will find additional information on this topic.