Seamless pipe: scope and manufacturing process

When creating plumbing systems it is very important to choose the right pipes, which will be the main part of the whole structure. It should be noted that even among metal products the choice is rather limited. The fact is that the seamless seamless pipe according to GOST created is considered one of the most practical, which means there is no point for such systems to look for other options.

Features and application

First we need to say that this material is the most common and can be purchased in almost all specialized stores. However, it should be remembered that its price is sometimes calculated in kilograms, and not in meters. Therefore, going shopping or making an order, you need to clarify this point.

Nomenclature

There are many different sizes of seamless seamless pipe. (See also the article The diameter of sewer pipes: features.)

In this case, they most often differ in diameter, since the remaining parameters may depend only on the manufacturer.

- The length of the products is set at the factory and can vary greatly.. The fact is that not all manufacturers cut pipes into a certain size, as this greatly increases consumption.

- Most manufacturers work according to GOST 8732 78. This allows you to make products with a very approximate length. However, they must not be less than 7 meters or exceed 14 meters.

- Given this feature, and sold by weight. At the same time, such enterprises sell a size pipe, but its cost may be slightly higher.

Tip! When purchasing pipes, you should immediately think about the transport that will deliver the purchase. It is on this feature should be guided in the first place.

Manufacturing

If you create a seamless pipe according to GOST, then for this use metal round timber. At the same time it is possible to use both carbonaceous, and the alloyed steel. It all depends on the desire to get a certain brand of pipe.

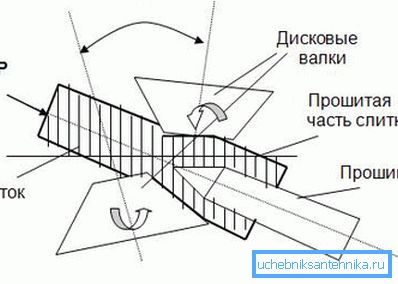

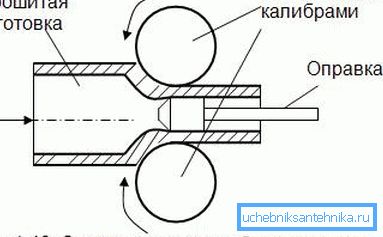

First, the metal is heated to a temperature close to the destruction of the crystal lattice. Then the round timber is punched in the middle and starts extending the hole to pull the pipe. It should be noted that all the work is done on a special machine, and the whole process is usually fully automated.

It is worth mentioning that the instructions for manufacturing involves the creation of a certain crystalline structure over the entire surface of the product. This is achieved by heating the already finished pipe to a certain temperature, after which it is cooled.

Tip! When purchasing this product is best to ask the seller in advance to provide a certificate of conformity to quality. Otherwise, you can purchase products with lower strength, which in some cases is very important.

Application area

First of all, such products are used for their intended purpose for the manufacture of plumbing systems or highways for supplying other liquids or compressed air.

At the same time, this material is in demand in almost all sectors of modern life, ranging from plumbing to aircraft construction.

- Some craftsmen, creating designs with their own hands, use pipes as supports and even piles. In this case, particular preference is given to products with a square cross section. (See also the article Garage of the profile pipe: features.)

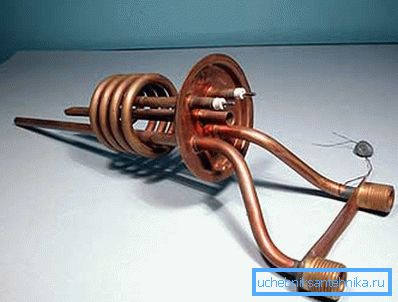

- Special attention should be paid to the fact that such products are very often used for the manufacture of various hollow cylindrical parts. This is due to the fact that it is much easier to use a piece of pipe in work than to grind out the necessary element on its own, consuming a large amount of metal. However, such blanks are significantly different from standard pipes that are used in the arrangement of water supply.

Tip! Practically in any economy even a small piece of pipe can be useful. Therefore, economical owners of summer cottages never throw away the remnants of the material after installation, and store it in the outbuildings.

Conclusion

After reading the video in this article, you can learn in detail about this type of pipe and their application. Also, taking into account the article above, it is necessary to conclude that this type of material is the most common and yet accessible from all that offers modern production. Recently, however, modern plastic structures have emerged that are beginning to displace metal pipes in the area of the water pipeline.