Sewer pipe manufacturers

The reliability of any sewer system depends, as is well known, not only on the quality of its installation, but also on the type of pipes used for this. That is why before starting the installation of a sewage system on any object, it is advisable to familiarize yourself with the existing varieties of pipe products, their main characteristics, as well as which manufacturers of sewage pipes produce material of proper quality.

It should be noted that for a long time, the cast iron pipes produced by our industry met the basic requirements for sewer lines.

Tip! In recent decades, cast iron products are gradually being squeezed out of the market by new samples of pipes manufactured using the most modern technologies from different materials. Moreover, in their technical characteristics, most of them are noticeably superior to such familiar to us, cast-iron tubular products.

Types of pipe products

In accordance with the material used in the production process, all known samples of sewage pipes are divided into the following types:

- ceramic;

- metal (made of cast iron or steel);

- concrete pipes;

- plastic pipes (polyvinyl chloride, polyethylene or HDPE).

Let's consider each of these pipe products in more detail.

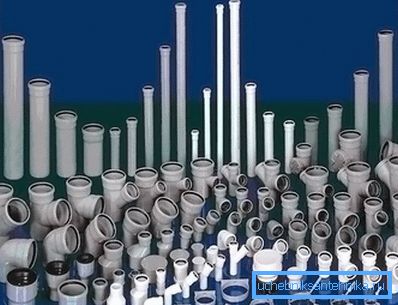

Plastic pipes

When conveyor production of plastic sewage pipes by most manufacturers, the method of so-called extrusion is used, through which a continuous process with a closed cycle is implemented.

The order of operations of this cycle can be represented as follows:

- First, granulated plastic enters a special extruder hopper.

- With the help of a special device (auger), plastic rotational granules are imparted to the granules, accompanied by their simultaneous fusion by ring heaters.

- The molten plastic granules in the form of a thick mass then get into the extrusion head, where under a high pressure a continuous pipe with a certain diameter is formed from it.

- The product thus molded is then moved to the vacuum processing section, where the pipe diameter is calibrated to a standard value.

- After that, in a number of cooling chambers, the temperature of the heated and formed billet is reduced to normal, after which it is cut into segments of the required length.

- For drawing the finished product, a special pulling device is used with tracks that reliably grab the tube blank and allow it to be removed from the molding mechanism without any damage.

- All cycles of the continuous workflow in the extruder are controlled using a special logic controller.

Tip! Many foreign manufacturers of PVC sewer pipes for their manufacture use low-quality plastic, since in Europe these products are mainly used for arranging external networks. At the same time, pipe products made in Germany enjoy the highest reputation.

Famous manufacturers

Before buying pipes for sewage, it is very important to correctly select a manufacturer whose products differ in the required reliability and long service life.

Wavin

Pipe products of the company Wavin, founded in 1955 and now settled in the city of Zwolla (Holland). Even in the last century, its founder Johan Keller decided to deal with the main drawback of water pipes - their corrosive destruction and the associated deterioration in the quality of drinking water. After he managed to do this, a number of European companies quickly mastered the production of products from the same material, but for sewerage needs. After that, companies and factories for the manufacture of products of this class began to spread throughout the world.

Pragma

Pragma polypropylene pipes differ from similar products from other manufacturers in the color of their walls and their structure.

Tip! The outer shell of such pipes has an orange color and is made in the form of corrugations, while the inner walls are white and smooth.

The length of the billets produced is 6 m, while at one end there is a rubber seal, and the second is shaped as a socket. Such pipes are intended mainly for work in the simplest non-pressure highways (in networks of external gravity sewage).

Korsis

Korsis sewage pipes are corrugated two-layer products made of propylene using Italian Polieco technology.

Tip! Products of this company are used mainly in the repair and rehabilitation works in storm sewage and domestic sewage systems, as well as in laying in-depth communications capable of withstanding a large radial load.

In addition, such pipes are used for removal of chemically active liquids and gases at ambient temperatures from 0 to 45? С. (at the same time it is allowed a short-term increase to 95? C). Sewerage pipes Korsis PRO with a diameter of 110 to 1200 mm and standard lengths of 6 and 12 m have stiffness allowing them to be laid without using a special protective sheath, i.e., directly below areas of possible surface loads (under road surfaces, for example).

Tip! Korsis PRO tube products are immediately recognizable by the smooth inner surface of a light blue color, as well as by the corrugated outer walls, which have a black protective coating with the addition of soot.

Ostendorf

Pipes under the name Ostendorf (Germany) are made of high quality special polypropylene, which absorbs sound well. They are used for the construction of domestic sewer networks and are compatible with products from other manufacturers. The presence on the outer wall of the centimeter scale, as well as the ease of the material itself, greatly simplify their installation.

Tip! The service life of Ostendorf products is at least 100 years.

Rehau

The main advantage of pipe products from Rehau is their ability to absorb noise. This is facilitated by the special three-layer structure of the polymer, reinforced at the branching sites, as well as the use of special noise-absorbing clamps for articulation.

Tip! The inner layer of Rehau pipes is resistant to corrosion, the middle one is reinforced with mineral additives, and the outer layer is shock and vibration resistant.

All elements of the Rehau pipe set, including special seals, are highly resistant to temperatures and aggressive media, which allows their use in any type of sewer networks, laid in special mines, in concrete (masonry) or behind suspended ceilings. The pipes have a nice white color that allows them to be used for external installation. The maximum lifetime of Rehau products is at least 50 years.

Polytec

The Russian company Politek specializes in the production of a wide range of elements of pipe systems, including the following names:

- polypropylene fittings and tubulars for internal and external gaskets;

- two-layer corrugated pipes of high strength of low-pressure polyethylene (HDPE);

- drainage pipes.

Tip! The majority of samples of pipe products Politek is made of stabilized polypropylene and is used in non-pressure sewage systems.

During their production, special substances are added to the starting material to improve the fire resistance - flame retardants. Due to this, the upper limit of temperatures that products of this class are able to withstand, increases markedly and amounts to +95? С. (compare: for PVC pipes, this figure is 60? C).

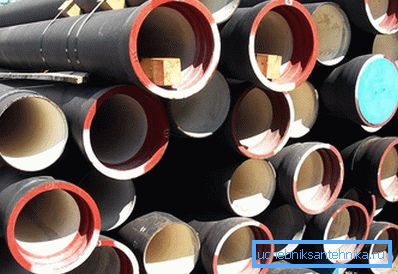

Modern cast iron products

Despite the fact that cast iron pipes are inferior to their plastic counterparts in many respects, the demand for some samples of these products (such, in particular, as Sml-free systems) is still quite high. The most famous manufacturers of such pipes should include the firms “Duker” and “Pam Global”, which manufacture products from foundry iron.

Next will be considered some of their features:

- First of all, we draw your attention to the fact that the main elements of these systems (fittings, tees and pipes) do not have bells as such. Their connection is carried out with the help of special clamps providing a butt-to-butt joint. It should be noted that the clamps are made of high-quality stainless steel, and the sealing cuffs use rubber that is resistant to aggressive media.

- Most often, these clamps are used in the construction of non-pressure sewer systems with a pressure inside the pipes of not more than 0.5 bar. If a special crimping cuff is mounted over the collar, the system is allowed to operate at internal pressures up to 10 bar.

- The use of special connecting clamps in the system allows to simplify all procedures related to its installation and disassembly. Indeed, to set the required bending angle of the sewer channel or to remove one of its elements, it is enough to loosen the fixing of the retaining clamps.

- Special shaped parts of such systems, as well as the pipes themselves, are manufactured in accordance with DIN 19522 / EN 877 standards used in the international classification.

- The diameter of cast iron pipes can vary from 50 to 300 mm, and their standard length is 3 m.

- All products of manufacturers of ironless products for sewer systems meet the standard requirements of GOST 6942-98.

- A special coating of modified epoxy resins reliably protects such pipes from possible mechanical and chemical damage.

Pipe systems of this class are ideally suited for operation in multi-storey buildings and office buildings, as well as in the premises of railway stations, airports, hospitals, supermarkets, hotels, underground parking lots, warehouses, as well as at facilities with special requirements for the level of noise and fire protection.

Video

From the video you can learn about the production of polyethylene pipes by extrusion:

If you are interested in learning about the production of corrugated polypropylene pipes, then we invite you to familiarize yourself with the following video: