Sizes of metal pipes and their influence on the particular

In this article we will talk about the diameter of metal pipes and how these or other sizes affect their throughput and scope.

The topic of the article is relevant, as the sizes are exactly the parameter that determines where the metal will be used, what capacity it will be characterized by, and what media can be transported through it. Again, sizes are of particular importance because, in accordance with these parameters, the price of the product is determined.

Features of application according to standard sizes

For a long time, metal pipes of large diameter, as well as their small-sized counterparts, are used in a wide variety of industrial fields and various areas of human economic activity.

Rolled metal with a radial cross-section configuration is widely used in construction, in the chemical and food industries, in agriculture in the automotive industry, etc. Of course, this list of applications is incomplete, but even looking at it you can understand that this type of hardware is very popular, and therefore is represented on the market by a wide choice of dimensions and configurations.

At present, welded, seamless seamless types of rolled steel with a round section are produced. Welded modification is characterized by simplicity of industrial production, and therefore its price is more affordable. Seamless products are more expensive, but they are more reliable, as they demonstrate high resistance to mechanical loads.

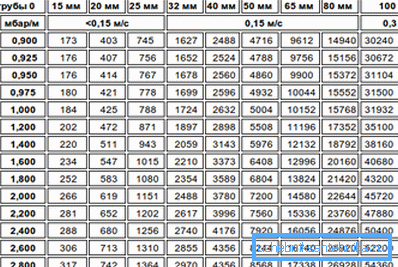

For greater durability, products from ferrous metals are processed by galvanizing. Regardless of the internal surface treatment methods, metal pipes have a lower throughput compared to polymer counterparts.

The most important parameter that must be considered when choosing and subsequent use of pipes is the size of the cross section. The diameters of the metal pipes should correspond to the size of the connecting fittings, with the use of which the assembly of plumbing, heating, sewer and other systems is carried out.

Internal and external dimensions of the section

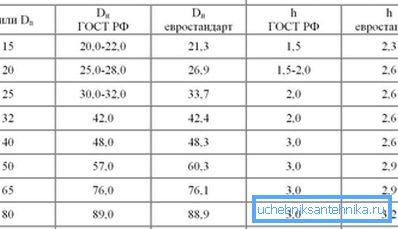

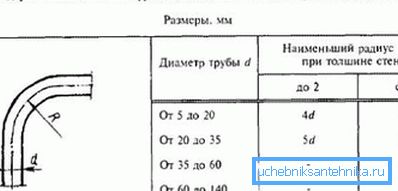

The difference between the internal size of the cross section and the external one is determined by the thickness of the walls. The thicker the wall, the more the outer diameter will differ from the inner diameter. Conversely, the thinner the wall, the smaller the difference.

That is why, when choosing components for assembly of various systems, the attention first of all turns to the dimensions of the internal space of the pipe.

Important: Along with the cross-section parameters, the wall thickness is of considerable importance, since taking into account this value at the design stage, it is possible to calculate the set long-term allowable load on the system.

The modern sizes and the range of metal pipes in accordance with GOST extends to all range of similar products which are made in the industrial way.

Having accurate information about these parameters, it is possible not only to select fittings and other accessories of the appropriate size, but also to correctly carry out design calculations for the construction of systems for transporting a particular environment. Moreover, with data on the external and internal size of the section, it is possible to design water supply and other systems, taking into account the presence of weak points and their subsequent elimination.

Traditionally, the marking of the parameters of steel and cast iron products used internal size. Marking on the copper rolled products is applied taking into account the outer diameter.

Features of sizes

The diameters of metal pipes are divided into the following categories:

- conditional;

- nominal;

- outdoor;

- internal.

Important: All the above parameters are indicated in millimeters in the designation of domestic products and in inches in the designation of products of foreign production.

Standardization of sizes

The first generally accepted table of the size of metal pipes appeared when uniform standards for connecting elements were developed, with the use of which plumbing, sewage, heating and other systems were assembled. The introduction of standard parameters has significantly expanded the scope of application of water components from steel and improve the quality of their assembly.

The appearance of uniform parameters entails additional advantages when carrying out large-scale design of various highways, since it is now much easier for specialists involved in development and design to select connecting elements, having accurate information about the external dimensions of pipes.

Now it is possible to choose and acquire various outlets, transitions, plugs, tees and stop valves knowing only one internal diameter. As a result, both an experienced technician and a novice plumber can cope with the assembly of plumbing or heating.

Classification in accordance with GOST

Let's find out the difference between a metal pipe 100 mm from similar products with other sizes.

In accordance with the regulations prescribed in the relevant state standards, plumbing components made of steel and metal alloys are classified according to the following indicators:

- The size of the outer diameter:

- up to 102 mm - small items;

- 102-530 mm - products of average value;

- 530-1420 mm - products of great value.

- The ratio of wall thickness and diameter:

- modifications with particularly thin walls;

- modifications with thin walls;

- modifications with an average wall thickness (normal products);

- modifications with thick walls;

- modifications with particularly thick walls.

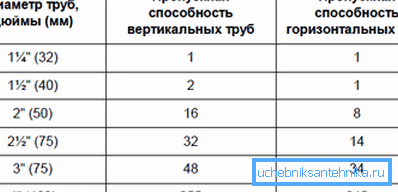

Important: When constructing plumbing and heating systems in buildings for residential and public use, pipes with an internal diameter in the range of 10-30 mm are used.

Selection according to size

Now let us try to determine what metal pipe 32 or similar products with smaller or larger cross-sectional dimensions can be used for:

- Metal pipe 20 mm is used in the device water supply systems from the riser to the tap.

- Products with a diameter of 40 to 50 mm, as a rule, are used to construct centralized systems for hot and cold water supply, as well as heating in residential buildings.

- Products with a cross section of 150 mm are used to create domestic and industrial water supplies.

- Products with a diameter of 273 mm have found wide application in solving a wide range of tasks characteristic of the chemical and oil industry.

- Galvanized steel products with a size of 325 mm and more are an excellent solution for the construction of complex centralized heating systems.

- Galvanized steel products with dimensions of 530-1020 mm are in demand when transporting liquid combustible media, such as natural gas and refined products.

- Products with an internal diameter of 630 mm are used in construction when constructing complex frame elements, industrial water diversion systems, etc.

Conclusion

So, now you know what is the instruction of the selection and application of pipes in accordance with their standard sizes. Given the variety of plumbing components and related accessories on the market, the findings will be useful and can be applied in practice.

Do you have any questions to clarify? In this case, more useful information can be obtained by watching the video in this article.