Soldering polypropylene pipes: how cheap to replace the

When installing a plumbing or heating system from plastic pipes, it is important to correctly connect all parts. Usually a specialized construction team is hired for this job. However, having learned how much it costs to solder polypropylene pipes, many decide to do all the procedures with their own hands. The method of operation and all the important nuances of this process are described below.

Self-installation of polymer parts

Tools used

The technology of soldering polypropylene pipes involves the use of a special welding machine, which in common people is called “ironing”. Its price is quite high, because if you are not going to professionally deal with the installation of water supply systems, it is advisable to rent this tool.

The device is light and compact. It works from a usual household electric network. Comes with a set of nozzles that are used for welding pipes of various sizes.

The instruction attached to the soldering iron describes in detail all modes of its operation. The soldering temperature of polypropylene pipes is very important here - the table given in the accompanying documentation for the device will help to correctly heat up and connect individual parts.

Before starting work it is recommended to make several trial packs. To do this, you need to buy additional fittings and dock. This will help calculate the correct time to solder polypropylene pipes.

Assembly process

A feature of plastic parts is that they can be laid in various ways:

- open secured with brackets;

- hidden in technical rooms;

- in specially equipped gates on the walls and under the floor.

If you strictly follow the rules of soldering polypropylene pipes, ready-made engineering network can serve you up to 20-30 years without problems and breakthroughs.

The essence of the process is as follows: using a soldering iron, it is necessary to heat two connected parts (pipe and fitting), and then connect them with each other and hold them for a few seconds until the plastic solidifies.

Note! The strength and durability of the connection depends not only on the correct heating temperature, but also on the accuracy and density of the pipes inserted into each other. If at the same time to allow distortions, the connection may collapse from the pressure of the fluid.

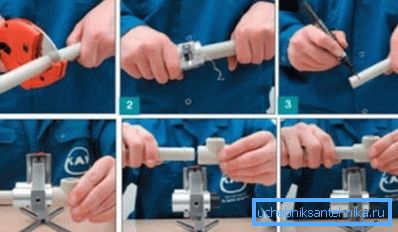

The soldering of pipes from polypropylene is made in the following sequence:

- Before starting work, it is necessary to turn on the soldering iron in the network and wait until its working body is heated to a temperature of 270 degrees Celsius.

- The ends of pre-prepared pipes of the required diameter and size should be cleaned of debris and burrs, as well as the remnants of aluminum foil (when installing reinforced parts).

- In order to better control the depth of fit of the pipe, you must insert it into the fitting and make the appropriate mark on the outer surface of the product.

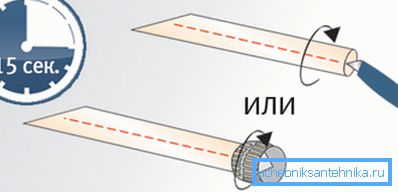

- After this, the parts are put on the soldering iron tips. They should enter as smoothly as possible. If during the melting process to allow distortions, the joining of water pipes will be of poor quality, which can lead to a gust during operation.

- After a few seconds (as soon as the plastic layer melts), they should be removed from the iron and inserted into each other until it stops. In this case, you will need to make an effort, but not excessive.

Note! Details can not be scrolled around its axis, otherwise the seam will turn out fragile and the work will need to be redone again.

- As soon as the docking is completed, it is necessary to hold the parts still for several minutes until the assembly is completely cooled. After this, the seam will become monolithic and airtight.

Remember that pipes should always be heated outside, and fittings for connecting pipes should be heated inside. If you ignore this rule, the engineering network will be unreliable.

The table of soldering of polypropylene pipes will help you to get the strongest connection, where the time of heating and cooling of various polymer parts, depending on their diameter, is indicated.

| Diameter | Heating time | Time permutation | Fixing | Final stand |

| sixteen | five | four | 6 | 2 |

| 20 | five | four | 6 | 2 |

| 25 | 7 | four | ten | 2 |

| 32 | eight | 6 | ten | four |

| 40 | 12 | 6 | 20 | four |

| 50 | 18 | 6 | 20 | four |

| 63 | 24 | eight | thirty | 6 |

| 75 | thirty | eight | thirty | 6 |

| 90 | thirty | eight | thirty | 6 |

| 110 | 50 | ten | 50 | eight |

| 125 | 60 | ten | 60 | eight |

When welding polypropylene pipes of small diameter, it is necessary to ensure that swollen plastic does not clog the internal space of the water supply system. After the assembly has cooled down, it is necessary to check its permeability by running water or blowing the product.

Common errors when soldering pipes

End face pollution

An experienced plumber always checks the ends and the internal space of the parts to be welded together. In case of dust or dirt, they should be thoroughly removed. Most often, the dirt sticks to the product when they are put on the dirty floor. Therefore it is recommended to keep clean in the room.

Moisture brings even more trouble. A few drops of water, which fell on the heated end, form steam, which leads to the deformation of the joint and the loss of its strength.

Tip! Salt or bread crumb will help to get rid of water droplets in the internal space of the pipeline. Of course, after the end of the work, these aids must be removed.

In addition, remnants of aluminum foil that is present in reinforced pipes can affect the strength of the joint. It must be carefully removed with a tweezer or a regular knife.

It is necessary to clear not only the pipes, but also the working element of the soldering iron. Molten polypropylene must be removed before processing the next compound.

Errors made during soldering of polypropylene pipes may not manifest themselves immediately. Sometimes the place of adhesion remains stable, but after some time (usually, up to a year) a leak appears.

Uneven docking

Having warmed up a pipe with a fitting and having inserted them each other, you have some seconds to give them a correct position. It is better to do everything as quickly as possible. If you exceed the time limit shown in the table, the deformation during movement will not allow the polymer to harden properly, which will lead to depressurization.

Many inexperienced craftsmen begin to remove the emerging influxes immediately after the connection. This is wrong, since such actions can lead to deformation.

Note! If during soldering of water pipes made of polypropylene, you constantly have nodules, it means that you overheat the pipes. Check the table again and reduce the heating time.

Poor pipe quality

The total cost of plumbing includes the cost of soldering polypropylene pipes and the material itself. Many, wanting to save money, buy cheap plastic parts, the quality of which leaves much to be desired.

It is hardly worth adhering to this practice, because as the famous saying goes, the miser pays twice. No matter how skillful the installer is, he will not be able to achieve a quality connection of such materials. And after a while you have to start work from scratch.

Another common mistake is connecting pipes from different manufacturers. Each plant independently develops the chemical composition of the polymer and, as a rule, they have different technical characteristics.

As a result, it is almost impossible to produce high-quality heating of such parts and, naturally, their docking.

Violation of the rules of installation

Incorrect connection may also occur due to errors during the connection of an already heated pipe:

- The pipe is not fully inserted into the fitting. In this case, a small gap forms between these parts. Its diameter is slightly larger, and the wall thickness is slightly smaller than that provided by engineering calculations. All this leads to leakage.

- Excessive force during pipe insertion into the fitting. In this case, a large influx is formed, which closes the internal space of the water supply system. This leads to a decrease in the capacity of the engineering network, which will adversely affect its work.

- Use damaged fitting. Some workers use broken connecting elements (especially if the whole is not at hand). A sealed butt joint will also not be able to last for too long and will eventually lead to leakage.

Conclusion

Soldering polypropylene pipes is an easy process. But you can achieve a really high-quality connection only by observing all the rules listed above. More details about the installation of plumbing systems can be found in the video in this article.