Square aluminum tube: scope and specifications

In modern construction uses a large number of different metal structures that perform a very different function. At the same time, they have a rather large weight, which affects the overall loads of the foundations. That is why many designers use such material as an aluminum square tube, which is almost as good as steel products and at the same time has a small weight.

Scope and characteristics

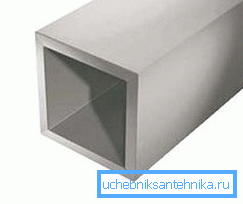

First we need to say that this type of material is made with a profile in the form of a full square. There are no joints or connections in it, which means that the loads will be distributed over all the walls evenly.

Properties

- Even the smallest 20x20 aluminum square tube can withstand rather heavy loads.. At the same time, it should not be used as a carrier system, since completely different products exist for solving such problems.

- Aluminum is very well drilled and processed by hand.. It allows to use bolted connections, completely having refused welding works.

- It is important to mention that this material is well tolerated by various environmental influences.. That is why it does not need a protective coating or additional processing.

- The most running is considered an aluminum square tube 40x40. It is great for most construction processes and is most often used in the installation of structures.

- Among the shortcomings of such products, it can be noted that if the use of welding is planned, then creating a reliable and high-quality weld will be obtained only when using special units or specific electrodes..

- It is also necessary to mention that the price of such materials is much higher than that of exactly the same structures, but from ordinary metal..

Tip! All work must be done in strict accordance with the project. Therefore, it is forbidden to replace metal elements with aluminum products. The fact is that a certain difference in strength still exists.

Application area

A typical 50x50 aluminum square tube can be used as pillars for fences, and a material with a smaller section is perfect for creating jumpers.

- Due to its anti-corrosion properties, such material is very often used to create structures that are located near the sources of salt water. The result is a structure that is not completely afraid of rust, sometimes caused even by sea air.

- Some varieties of such pipes are great for creating decorative elements. However, you need to select the appropriate type of material.

- It should be noted that a typical installation manual involves the use of such products for a bunch of supporting elements, columns or structural details. (See also the article Frame made of pipes: features.)

- Also, such a pipe can be used to create crates, if a typical profile can not withstand a large weight cladding panels.

- Very often, such a profile is used for the manufacture of various equipment and even tools. It allows you to make lightweight products that are easy to transport.

Tip! Given the high cost of such products, experts recommend using it only in situations where it is necessary to lighten the entire product or system in an active environment. At the same time, it is necessary to consciously go to such expenses only in strict accordance with the project.

Recommendations of the masters

- If the work is done by hand, then it is necessary to determine in advance the scope of such pipes and the need to use them. Otherwise, you can get a big overspending on finances with a design of excellent quality, which could be replaced with cheaper products.

- It should be noted that welding or brazing aluminum requires not only the availability of special equipment, but also the availability of appropriate skills from the contractor. Therefore, such work may cause certain difficulties. (See also the article Butt-Weld Pipe: Features.)

- It is also important to mention that with intensive heating products made from this material may undergo a certain deformation. Therefore, experts in the design of structures try not to make too large spans and install additional stiffeners.

Conclusion

After studying the video in this article, you can get more complete data on similar types of products and the method of their installation. In this case, based on the text presented above, it should be concluded that this material has a number of positive qualities, but they all fade into the background when the issue of cost is raised.