Square and rectangular tube - types and features of this

Square and rectangular pipes are now actively used in almost all areas of industry. This configuration significantly increases the technical characteristics of the strength so necessary in construction, automotive design and in the manufacture of furniture. Every year the range of profile pipes is growing steadily, compared to the range that was produced 20 - 30 years ago, it increased by more than 2 times.

Why rectangle

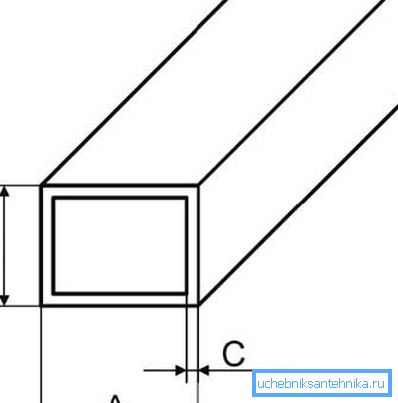

Round section is well suited for transporting liquids or gases. The cylindrical shape holds the pressure better and is much easier to manufacture. But the profile products are more resistant to external loads. The configuration and dimensions of rectangular tubes are such that they have 2 transverse ribs.

Varieties of products

All pipes with square or rectangular section are conventionally divided into 3 types.

- The most common type is considered to be welded construction.. Such a product is made from sheet metal bent and welded on special equipment. Metal welded rectangular pipes according to GOST 30245 are regulated. The price of such products is the most acceptable, therefore they are used more often.

- Hot-rolled products, have rather high operational characteristics, they are more expensive in production, but this technology allows producing pipes with clearly defined parameters.

- Structures made on cold rolling mills, initially have high strength, but weak elasticity. To increase the elasticity of the technology used "vacation". The metal is heated to a certain temperature and slowly cooled.

Important: any assortment of rectangular pipes according to GOST 8639 82 regulates the production of all-rolled products on tube rolling mills for hot and cold rolling.

What are the advantages of square and rectangular products?

- As mentioned earlier, due to the presence of natural parallel stiffeners, such structures have much higher strength than hot rolled pipes of the same section. Plus, hot-rolled metal is disproportionately heavier and bulky.

- At the present time, almost all metal products are subject to anti-corrosion treatment, which provides a significant increase in service life. Stainless and alloy steels do not initially need such processing.

- The rectangular or square shape of the pipes is well mounted on vertical and horizontal flat surfaces. Such designs are convenient to sheathe any finishing materials.

- In hollow products it is easy to place any communication. From cable lines to water supply.

- Rectangular or square designs are more convenient to store, pack and transport, compared with a circular section, these products take up much less space.

As for the calculations

To cover the entire range of rectangular pipes in one article is unrealistic. But the main thing to remember is that during the purchase and for transportation the weight of a rectangular pipe is of great importance, since the metal bases release the products by weight.

The weight of a running meter of a rectangular pipe depends on its size in cross section and wall thickness. Under field conditions, this value can be calculated as well as the weight of the sheet metal. In other words, to make a design scan in square meters, multiply by a fixed, in tables, the specific weight of this metal in grams and by the wall thickness in millimeters.

Values obtained by such calculations will be approximate. Of course, you can use them if you didn’t have a table with exact data at hand. It is even better if you can use an online calculator with which you can accurately calculate the weight of a rectangular pipe.

For example, we present a part of the table compiled according to GOST 8645 82 for steel structures. The same GOST for rectangular pipes regulates the parameters of products from stainless, alloyed and other special grades of metal.

Steel pipe weight.

| Rectangular tube section | Wall | Weight 1m / p |

| 20 X 15 mm | 1.5 mm | 0.810 kg |

| 20 X 15 mm | 2.0 mm | 1,070 kg |

| 25 X 15 mm | 1.0 mm | 0.620 kg |

| 25 X 15 mm | 1.5 mm | 0.930 kg |

| 25 X 15 mm | 2.0 mm | 1.225 kg |

| 30 x 20 mm | 1.5 mm | 1,178 kg |

| 30 x 20 mm | 2.0 mm | 1,554 kg |

| 40 X 20 mm | 1.5 mm | 1,401 kg |

| 40 X 20 mm | 2.0 mm | 1,853 kg |

| 40 X 25 mm | 1.5 mm | 1,554 kg |

| 40 X 25 mm | 2.0 mm | 2,057 kg |

| 50 X 20 mm | 1.5 mm | 1,660 kg |

| 50 X 20 mm | 2.0 mm | 2,198 kg |

| 50 X 25 mm | 1.5 mm | 1,778 kg |

| 50 X 25 mm | 2.0 mm | 2,355 kg |

| 50 X 30 mm | 1.5 mm | 1,849 kg |

| 50 X 30 mm | 2.0 mm | 2,449 kg |

| 50 X 40 mm | 1.5 mm | 2,100 kg |

| 50 X 40 mm | 2.0 mm | 2,790 kg |

| 50 X 40 mm | 2.5 mm | 3,470 kg |

| 60 x 20 mm | 1.5 mm | 1,849 kg |

Important: in the tables of profiled products indicated the theoretical value of the mass of the material. Standards allow the deviation of theoretical data from the actual weight within 12%.

Where are used tubes

Now almost every construction site uses profiled material. Remember how fast modern shopping malls, pavilions, exhibition halls and other similar structures are growing. All this became possible because the frame in them is assembled from metal beams and profiled pipes.

Construction, one of those areas where the external stability of pipes is claimed. Tightness of products in supporting building structures fades into the background. There is a separate GOST for rectangular pipes made by welding technology.

The range of rectangular pipes according to GOST 30245 2003, currently has the widest range of sizes for welded products.

Important: an I-beam in its characteristics of strength exceeds the profiled pipe, so square and rectangular pipes are used in intermediate, open structures, with an average load level or in places where the aesthetic side of the issue is important.

But profiled products in construction are used not only for the manufacture of bearing beams in high-rise buildings. No less popular is this material when arranging lightly loaded and technological structures.

Rectangular bimetal railing can be found in any office. Rectangular plastic pipe, well suited for arranging hidden cable lines in high-rise buildings. And finally, temporary collapsible exhibition or trade pavilions, as a rule, are made precisely from such a profile. (See also the article Cable laying in pipes: features.)

This form is widely used in the manufacture of furniture. We all went to school and remember, not always beautiful, but reliable and durable desks and tables, assembled on the basis of square or rectangular tubes. Modern furniture designers also do not overlook these profiles.

Now almost any moving wheeled vehicle has in its design bearing elements made of square or rectangular tubes. From the cart in the country, the trailer to the car and ending with a sports high-speed race car, there are such pipes everywhere.

And finally, country greenhouses, which both quickly assemble and quickly disassemble their own hands, are often made of exactly shaped light metal. Instructions for the assembly of such structures takes no more than 1 page and is understandable at an intuitive level.

The video in this article shows profiled tubes.

Conclusion

No one will argue with the fact that there are no universal materials in nature. Square and rectangular pipes are also no exception. But in many areas of the construction and manufacturing industries they are an indispensable material.