Square metal pipe: the main characteristics, features of

In this article, we will talk about what a square pipe is made of metal, how it is made and what its scope is. The topic of the article is relevant, as the metal, which will be discussed further throughout the country is used in both industrial and individual construction.

In addition, such a pipe is used for household purposes in the arrangement of fences and temporary building structures. The popularity and demand for the product is largely due to the shape of the cross-section, since the square cut guarantees a number of advantages in comparison with the round shape of the cross-section.

So, what is the instruction for making square pipes, and what are the characteristics of these products?

Main characteristics

Chrome square tube, as well as analogs made of ferrous metals, is one of the types of rolled metal.

Products with a square cross-sectional shape, in contrast to round counterparts, are called profiled. With rare exceptions, these pipes are manufactured using low-alloyed and carbon steels, such as for example 09G2S and St3SP. In some cases, for the production of such steel, stainless steel alloys are used, which are characterized by increased resistance to the negative effects of environmental factors.

A more affordable price is peculiar to the profile pipe, which is not made of stainless steel, but of ordinary zinc-coated sheet steel.

The following qualities are peculiar to such products:

- durability due to high corrosion resistance;

- less weight compared to stainless steel;

- affordable price;

- ease of machining and, as a result, simple installation;

- possibility of carrying out both bolted and welded connections;

- wide range of sizes, so you can purchase exactly those pipes that are necessary to perform certain works.

Manufacturing process

Stainless square pipe is manufactured at special metallurgical enterprises. By production methods of cold and hot deformation of metal preparation are used. A round-welded pipe is used as a deformable billet.

Metal rolling production is carried out on full-cycle production lines as follows:

- Strip strips supplied in the form of sheet steel coils are cut into strips of the required width.

- Cut steel is fed to the forming rolling mill, where it acquires a rounded shape.

- Next, the workpiece is welded along the seam.

- Formed on the site of the weld, the influx (bur) is cut flush with the surface of the product.

- In the next step, the round billet, by means of special metal rollers for pipes, is deformed, giving its cross-section a square or rectangular configuration.

- In order to eliminate the possibility of a manufacturing defect, the weld is subjected to inspection using an eddy current detector.

- At the final stage, the product is cut into segments of the required length and subjected to heat treatment. At this stage, it is possible to remove from metal all the fatigue stresses that appeared during the deformation, and thus provide the required degree of strength.

Important: To ensure adequate resistance to the corrosion process, the finished metal is galvanized. During this process, the entire product is covered with a thin layer of zinc, which prevents the formation of corrosion centers and allows you to apply the rolled products under the open sky.

The described technology is used exclusively on large enterprises equipped with appropriate production facilities. Smaller enterprises use technology that eliminates the need for deformation of round pipes.

The production process, in order to reduce the cost price includes the following steps:

- the strip is cut into strips of the required width;

- stripes are deformed immediately, taking into account giving a rectangular shape;

- the product is welded and subjected to heat treatment with subsequent examination of the seam at the time of the presence of voids and cavities.

Important: The technology allows to produce products that meet the requirements of GOST 8639-82. But according to statistics, the operational life of such metal-roll is somewhat less in comparison with analogues made using the technology including a full cycle.

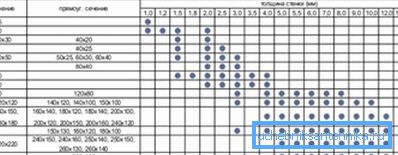

Actual standard sizes

In accordance with the standards governing the manufacture of profile metal, such dimensions of square metal pipes as the side from 32 to 60 mm are allowed, with a wall thickness of 4 to 6 mm.

Profile pipes available on the market can be manufactured taking into account the following lengths.

Measured length:

- for hot-rolled seamless modifications from 4 to 12.5 m;

- for cold-formed seamless modifications from 4.5 to 11 m;

- for electric-welded pipe modifications from 5 to 9 m.

Unmeasured length:

- for seamless hot-rolled modifications from 4 to 12.5 m;

- for electrowelded or cold-formed seamless modifications from 1.5 to 9 m.

Scope of application

Galvanized square tube has found wide application, both in the construction of industrial facilities, and in individual construction. In addition, this metal is used in the manufacture of high-voltage transmission lines, in the assembly of complex architectural structures, such as carcasses for domes, arches, etc.

And, perhaps most importantly, the production of factory and home-made greenhouses does not do without the use of profile metal.

Conventionally, the profile tubes can be divided into thin-walled and thick-walled modifications.

Belonging to one type or another most directly affects the features of the application.

- Thick-walled metal is primarily used to assemble frames for the construction of modern construction projects.

- Thin-walled steel is universally used for making light partitions with your own hands, advertising stands, bus stops, greenhouse frames and other structures that are not exposed to significant mechanical loads.

Conclusion

Now we know what are pipes with a square cross-section. We also found out where these products can be applied to destination. More useful information you can find by watching the video in this article.