Square tube - universal building material

Profile piping has a number of useful features that somewhat expand the scope of its use in comparison with a circular section. In particular, the flat surface makes it easy to use it for the installation of various structures. Also, due to its shape, the process of connecting individual elements into complex structures is facilitated.

general information

Such a pipeline can be produced both from steel and plastic, for example, from PVC.

The material largely determines the scope of the use of rolled products, such options are possible:

- steel pipe of this form is not suitable for the organization of water supply or heating system. But it can be used to create frames from pipes of various sections and even to make furniture with your own hands. A relatively small section can be used to block large spans, for this purpose trusses are made of them, and large sizes can be used as bearing elements, for example, columns;

- Square plastic pipes, of course, do not have the strength of a metal, therefore the area of their use is limited by the permissible load. For example, plastic piping can be used for nipple watering systems in poultry farms. Racks of plastic fences can be made of a larger standard size, as cable channels, air ducts, etc.

The use of rolled steel in ASG

The use of such a pipeline in industrial construction is somewhat different from the construction of an individual. First of all, the scale of the tasks and the load on the structure. Given the popularity of the rolled products, it makes sense to more detail the regulatory requirements and its use.

Regulations

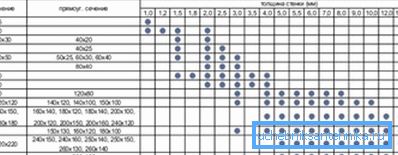

The GOST for square pipes contains the basic requirements for the geometric dimensions, tolerances for them, and the standard sizes are indicated in the assortment.

The situation with regulatory documents differs depending on the material:

- for the steel pipeline, there are 3 main standards: GOST 8639-68, GOST 8639-82 and GOST 30245-2003. The latter document combines basic information not only in square, but also in rectangular section. In the same documents you can find the weight per meter of a square pipe;

- as for plastic pipes, as such, the regulatory document for them does not exist. Therefore it is necessary to rely more on the information of manufacturers.

Use of the profile pipeline

In individual construction, small sizes are usually used. In this case, its scope is limited to the frame of the pipes under the greenhouse or racks for the installation of the fence. At the same time, the load on it is relatively small, so the weight of a square pipe does not play a big role.

In industrial construction, such material allows several times to reduce the time spent on the construction of structures. Particularly valuable is the fact that it can be used to cover significant spans. This technique is widely used, for example, when spans are blocked in industrial shops, hypermarkets and other large-scale facilities.

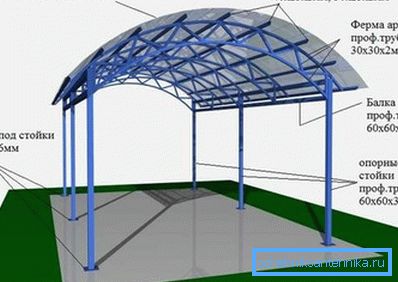

The only problem in this case is the mass of the square pipe, if you simply block a large span with a long pipeline, it will collapse only under its own weight. Therefore, for the overlap of large spans are made farm.

Pipeline trusses

Any farm consists of such elements as a belt (upper and lower) and bracing. In addition to the profile of the pipeline, they can be made of I-beams, corners and other rolled products. But trusses from rolled products are much more convenient to manufacture, while the weight of the structure remains small (it can be determined by GOST).

Farm can be classified according to the form, there are such types:

- with parallel belts;

- in the form of a triangle. A triangular square tube truss can be used, for example, as the basis of a truss system;

- trapezoidal;

- arched.

Note! To create an arched truss, you need a pipe bender. Instructions for its use is extremely simple - just enough to stretch the pipe between the rollers. It is better not to bend the profile rolling manually, the risk of spoiling it is great.

In the manufacture of special attention should be paid to the nodes of the truss from a square pipe. The geometry of the nodes strongly affects the operation of the structure under load.

Features of assembly units

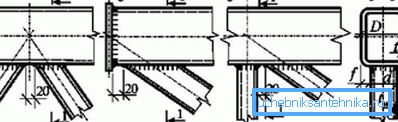

A node is a point at which at least 3 sections of a pipeline meet.

Most commonly used such methods of association:

- using welding;

- using bolts or rivets;

- additionally, you can use reinforcing knits;

- it is allowed to use expansion braces, supports to strengthen the node.

It is allowed to combine the elements of the farm as butt and overlap. At the same time the standard size matters, the sizes of a square pipe can be learned from a range.

Note! In a welded union, a metal gasket may be additionally used if the wall thickness is insufficient. Otherwise, the metal can simply be burned.

When assembling a unit, it is especially important not to displace individual elements relative to their design position. The axes of the belt and braces should intersect at one point, only in this case both braces will be loaded evenly.

However, there are exceptions to this rule. For example, in the case of using different sizes in braces or if there are restrictions due to the geometry of the belt, the centering of the node is allowed. The influence of the centering is noticeable in the plot of moments, the weight of the square pipes was also taken into account when constructing it.

Separately, it is necessary to mention the consolidation joints. Bolting can be used for this. In the case of bolts, high-strength bolts are used for the tensioned joint, and made of carbon steel for compressed.

Note! In case of flange joining of pipes, it is necessary to increase the rigidity of the flange in the stretched zone. To do this, you can simply reinforce the ribs, the price of such a solution is minimal, and the design is guaranteed not to collapse under load.

In conclusion

Profile piping is a versatile building material. Due to its geometrical characteristics, it can be widely applied not only individually, but also in industrial construction. The article focuses on the use of rolled steel in construction.

The video in this article shows an example of using a square pipe in individual construction.