Square tubes: 2 methods for the production of profiled

Square metal tube is one of the most popular types of rolled products. Such products are produced in a very wide range, which is largely due to the huge range of tasks for which such pipes are used.

In our article we will talk about the technology of production of these products, and also pay attention to the scope of their use.

Manufacturing process

Method 1. Rolling production

The manufacture of tubular products of rectangular and square sections is regulated according to GOST 8639 - 82.

According to this document, such products are produced:

- Seamless hot-rolled.

- Seamless cold.

- Electrowelded cold-formed (folded).

Pipes without technological seam are made by rolling technology.

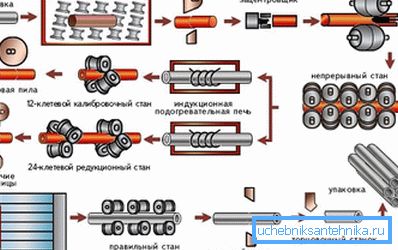

Production instructions include the following operations:

- Square all-metal billet (rod) is heated in a furnace to a certain temperature.

- Then the blank is placed in the press, where the product profile is formed using a special calibrating device.

- In the "cold" method of production, the sleeve is cooled, and then fed to the rolling mill, where it is processed before reduction to the nominal size.

- In the “hot” method, finish rolling is performed on a preheated part. This allows the manufacture of pipes with thinner walls without the risk of deformation.

- Then the metal is released. This is done in order to restore the natural granularity of the surface of the product, smoothed out during processing at the rolling mill.

Note! After completion of rolling and tempering, all products must be checked for compliance with the design dimensions. Pipes that have deviations in the cross section or wall thickness are rejected.

This applies to metal products. The plastic profile pipe is most often produced by extrusion technology, in which the workpiece is pulled through a sizing device - a spinneret.

Method 2. Welded manufacturing

Suture products are made somewhat differently:

- At the first stage of production, a steel sheet of a certain thickness (most often alloyed steel from 3 mm is used) is cut into blanks in the form of strips - the so-called strips.

- Next, strips are fed to the folding unit, where the profile of the future pipe is formed with the help of roller mechanisms of different sizes.

- Designed billet enters the area of welding, where the seam is formed.

Note! Industry produces only longitudinal pipes of rectangular and square profiles: there are simply no spiral-seam models.

- Next, the product is placed in a rolling mill for final processing. At this stage, the pipe is calibrated, the wall thickness is flattened and the surface is cleaned.

- Before shipment of finished parts to the warehouse, a flaw detection of the seam is mandatory.

Note! The allowable amount of bur (thickening on the surface at the weld penetration point) is from 0.5 to 1 mm. If these dimensions are exceeded, an additional cleaning of the pipe surface may be carried out.

The range of square tubes according to GOST 30245 - 2003 (namely, this document regulates the production of suture-type products) is quite extensive.

It includes:

- Square blanks from 40x40 to 300x300 mm.

- Rectangular blanks from 50x25 to 400x200 mm.

In some cases, other production technologies are used. So, in the presence of a round pipe of the appropriate size, it is possible to make a square or rectangular one by hand using a rolling mill for pipes. However, the quality of such a product will be very doubtful, therefore, it is strongly not recommended to use such parts for responsible work.

Use of shaped tubes

The main advantages

The advantages of square tube blanks include the following:

- High technology - if desired, the parts can be given almost any shape, and the installation of structures is carried out with relatively little labor.

Note! The shape with flat edges makes it easier to dock pipe products with brick and concrete surfaces: the gap is minimal and much less effort is required to seal it.

- Connection reliability both with use of welding, and at installation on arms with use of fixture.

- Good load bearing capacity due to the verified geometric shape and the minimum number of welds.

- High corrosion resistance and the impact of other environmental factors, which is provided primarily by involvement in the production of high-quality steel.

- Good fire resistance.

If we talk about the financial side of the issue, the price of such products can be considered quite affordable. Naturally, it is different for varieties using different steel grades, but in most cases it is possible to choose an option even for budget construction.

Scope of application

Profile pipes are perhaps one of the most versatile building materials.

The scope of their use is extremely wide and includes:

- Frame construction. Details are used for the construction of supporting structures of residential buildings and farm buildings, as well as for small architectural forms - sheds, gazebos, greenhouses, etc.

- Roofing. Square or rectangular pipes can be used as the main material for rafters and floor beams, especially where the roof does not require high thermal insulation values.

- The construction of enclosing structures, frame farms, elements of outdoor advertising, etc.

- Making furniture. Here the profile acts as legs and frame elements, ensuring uniform distribution of loads.

Conclusion

Frameworks, gazebos, fences, trusses of square tubes can be produced with minimal metal working skills. Such blanks are distinguished by the highest manufacturability, which ensures their popularity as a universal material. Learn more about the technology of production of square pipes, as well as how to use them, by studying the video in this article.